Main machine apparatus for testing lubricating performance of fuel oil

A technology of lubricity and test equipment, which is applied in the field of host equipment for diesel lubricity, determination of gasoline, and host equipment for determination of fuel lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] According to the following detailed description of specific embodiments of the application in conjunction with the accompanying drawings, those skilled in the art will be more aware of the above and other objectives, advantages and features of the application.

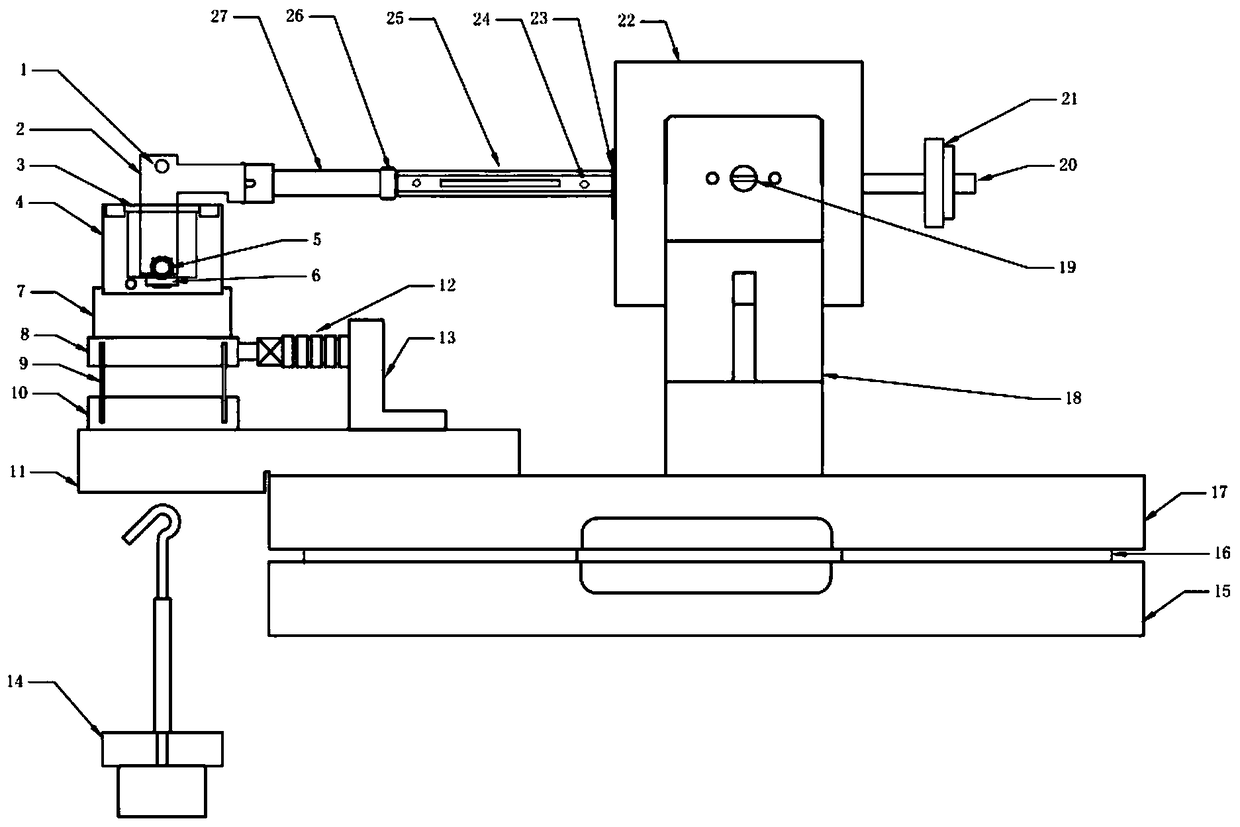

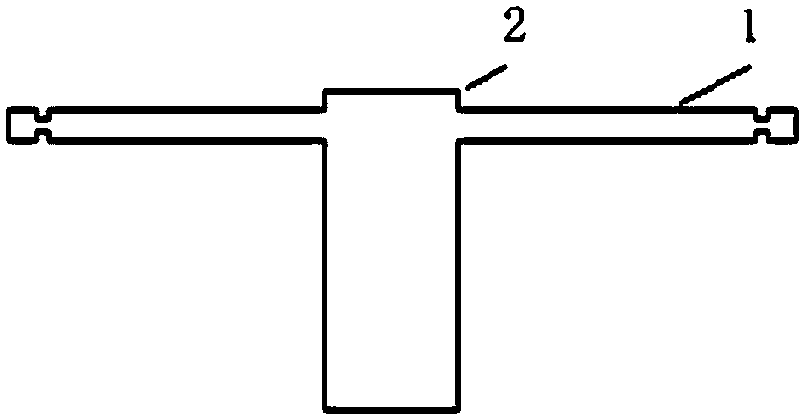

[0040] Embodiments of the present application provide a device for testing fuel lubricity. figure 1 is a schematic structural diagram of an embodiment of a device for testing fuel lubricity according to the present application. The device includes: a vibration exciter assembly, a heating and vibration measuring assembly, a drive shaft assembly with a length adjustment function, and an anti-vibration base assembly. The device can evaluate the lubricity of gasoline and diesel through high-frequency reciprocating test.

[0041] The anti-vibration base assembly includes: an upper plate 17 of the anti-vibration base, an anti-vibration pad 16 and a lower plate 15 of the anti-vibration base, and the anti-vibration pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com