A Pad Structure

A pad and contact structure technology, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as failure, device performance and yield reduction, damage to pad devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

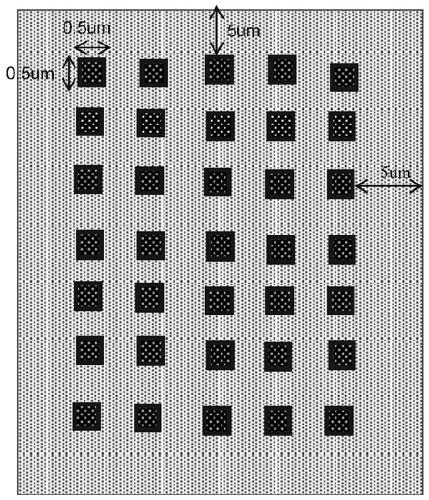

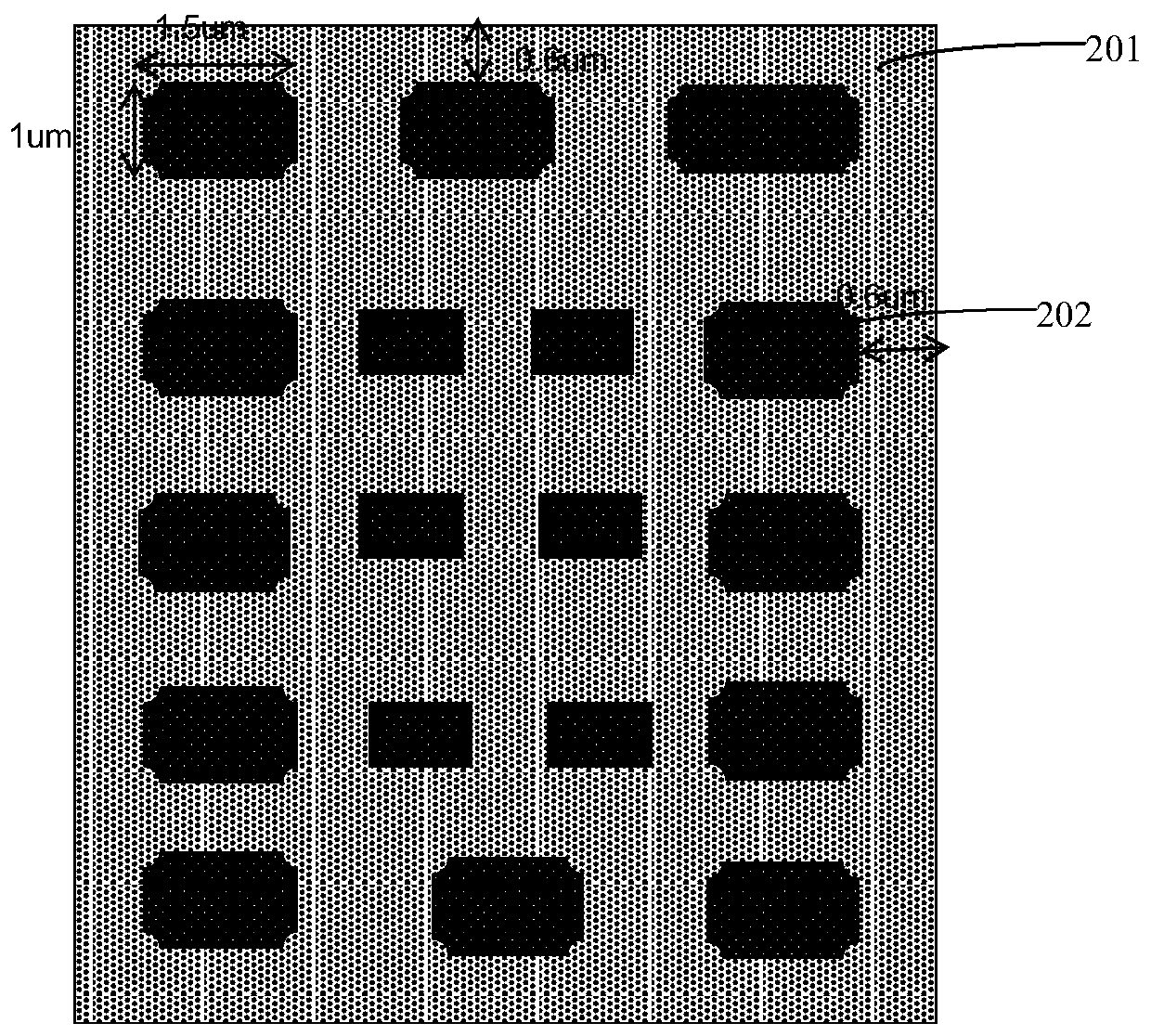

[0042] The preparation method of the semiconductor device of the present invention is described in detail below with reference to the accompanying drawings, figure 1 A top view of a pad structure in the prior art is shown; figure 2 A top view of a pad structure in an embodiment of the present invention is shown.

[0043] In order to solve the current problems, it is necessary to ensure that the top view area of the through hole, that is, the contact structure will not decrease, while the side wall area of the contact structure will decrease. Therefore, the present invention provides a solution based on the above research and analysis. A pad structure such as figure 2 As shown, the pad structure includes a contact structure 202 and a pad layer 201 disposed on the contact structure for electrical connection, and the contact structure includes several contact units arranged at intervals;

[0044] At least one of the contact units is integrally formed with another contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com