Cutting machine capable of automatically switching sawblade

A technology for automatic switching and cutting machines, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of saw blade damage, operator danger, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

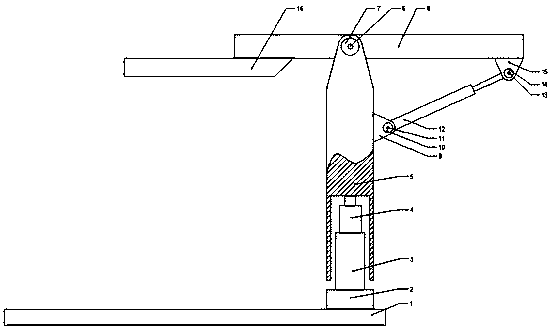

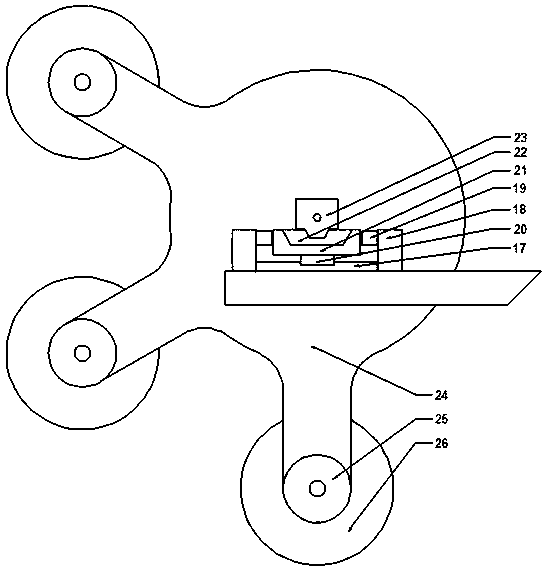

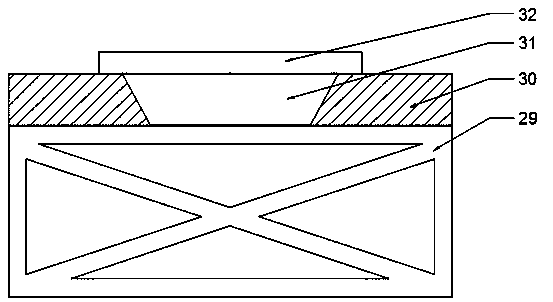

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a cutting machine that can automatically switch saw blades includes a base 1, the base 1 is located above the ground, and a saw arm mechanism is respectively arranged above the base 1, and the saw arm mechanism is fixedly connected by a The saw arm base 2, the saw arm heightening linear motor mounting frame 3 fixedly connected above the saw arm base 2, the saw arm heightening linear motor 4 installed on the saw arm heightening linear motor mounting frame 3, the saw arm heightening linear motor 4 The saw arm heightening frame 5 fixedly connected to the telescopic end, the saw arm heightening frame bearing 6 installed on one end of the saw arm heightening frame 5, the saw arm rotating arm shaft 7 inserted on the saw arm heightening frame bearing 6, and the saw arm rotating arm The saw arm rotating arm 8 fixedly connected to the shaft 7, the rotating arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com