Complex adjusting mechanism for nozzle

An adjustment mechanism and nozzle technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of increasing the burden on workers and inconvenient adjustment of nozzles, so as to improve automatic adjustment ability, reduce labor burden, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

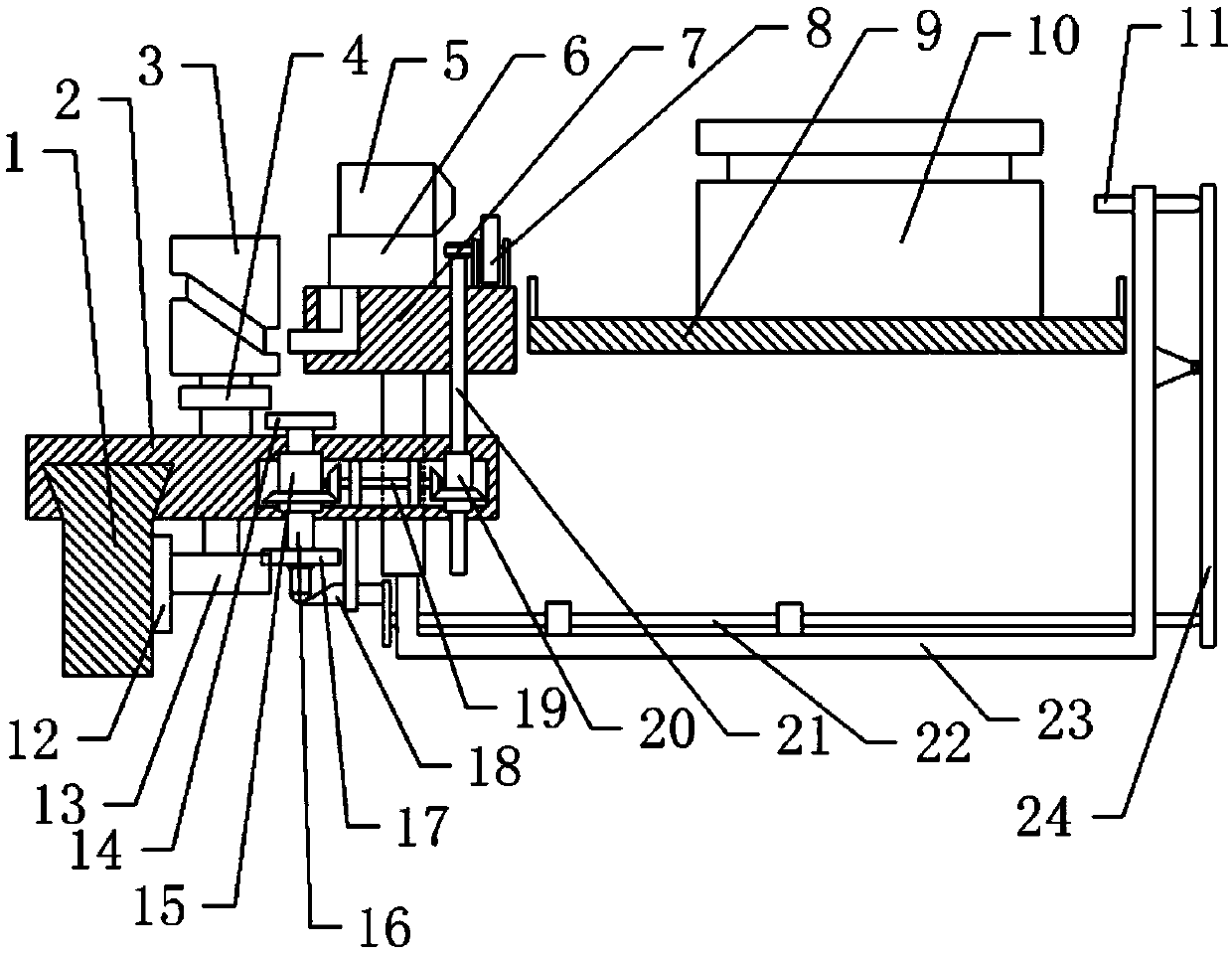

[0016] The reference signs in the drawings of the description include: guide rail 1, slider 2, cylindrical cam 3, vertical drive gear 4, nozzle 5, mounting seat 6, support block 7, wind wheel 8, material tray 9, workpiece 10, top Rod 11, rack 12, transverse drive gear 13, upper drive gear 14, second drum 15, second shaft 16, lower drive gear 17, wedge 18, drive shaft 19, first drum 20, first shaft 21, push rod 22, mobile frame 23, lever 24.

[0017] The embodiment is basically as attached figure 1 Shown: the composite nozzle adjustment mechanism, including a bracket (not shown in the figure), the bracket is provided with a horizontal adjustment assembly, the horizontal adjustment assembly includes a horizontal guide rail 1 welded on the bracket, and a rack is arranged on the guide rail 1 along the length direction 12. The rack 12 is connected to the guide rail 1 through bolts; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com