Assembled decoration suspended ceiling

A prefabricated and suspended ceiling technology, applied to ceilings, building components, buildings, etc., can solve problems such as low efficiency, high noise, high cost of curved roofs, and shaped roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

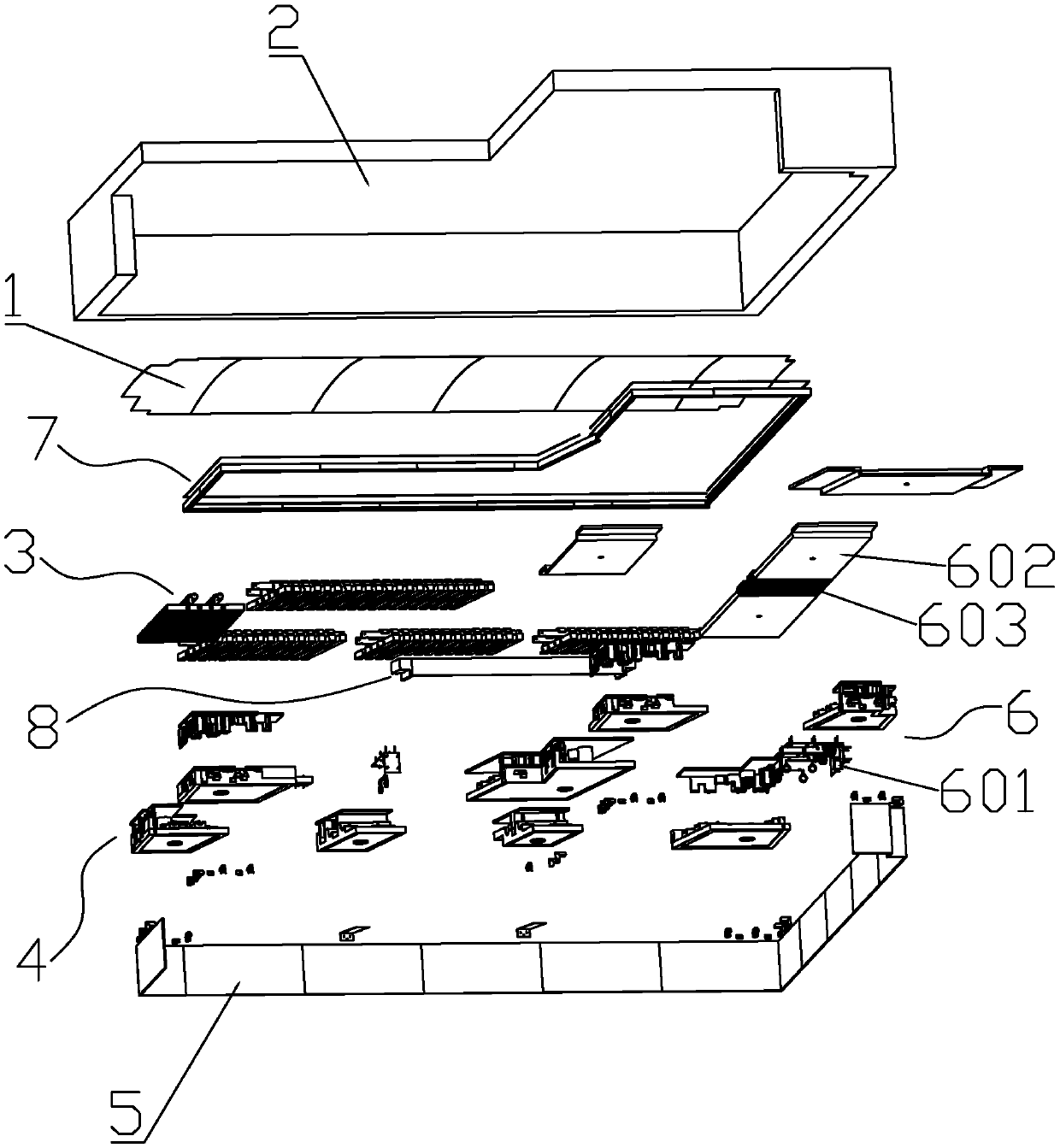

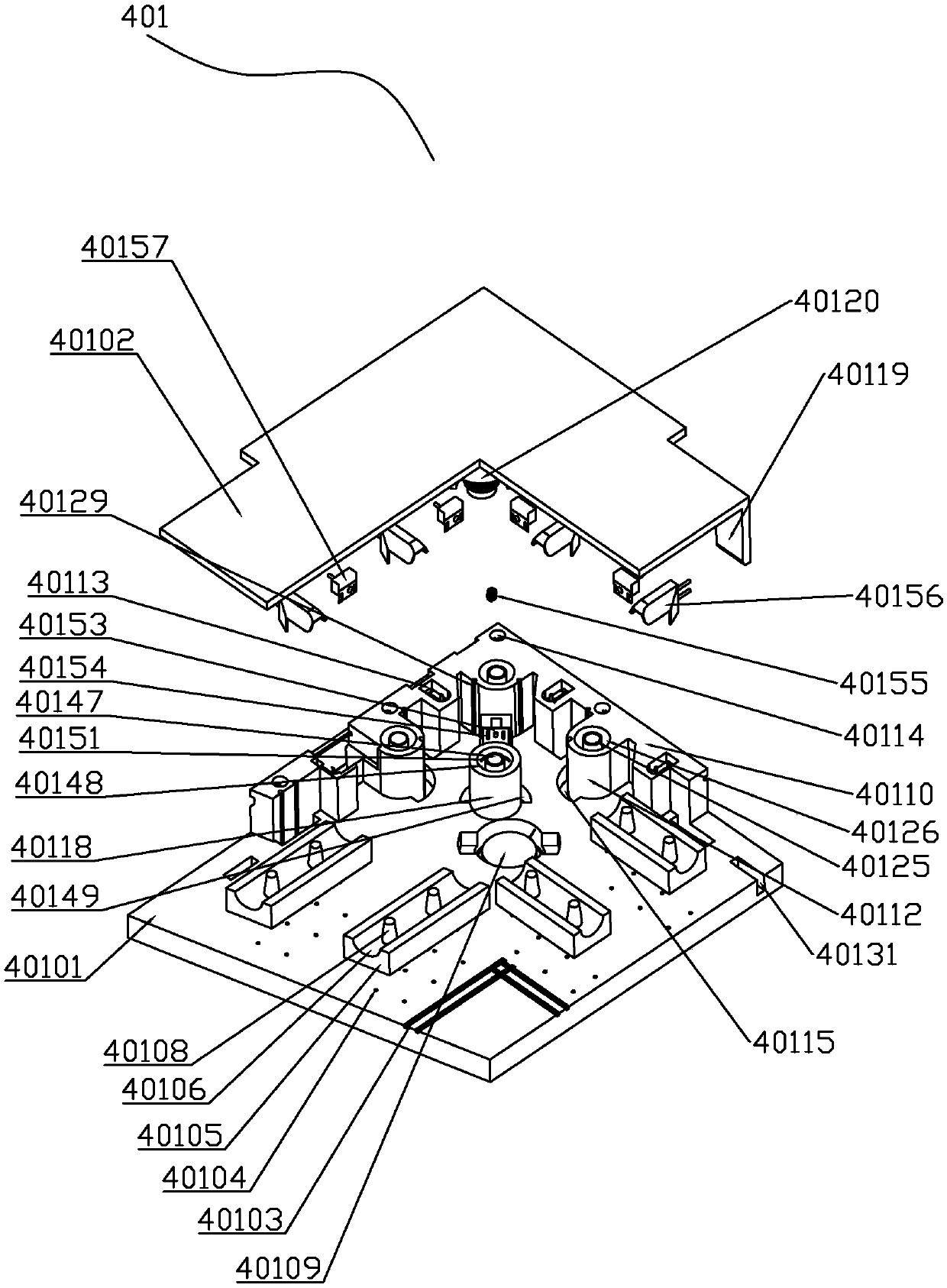

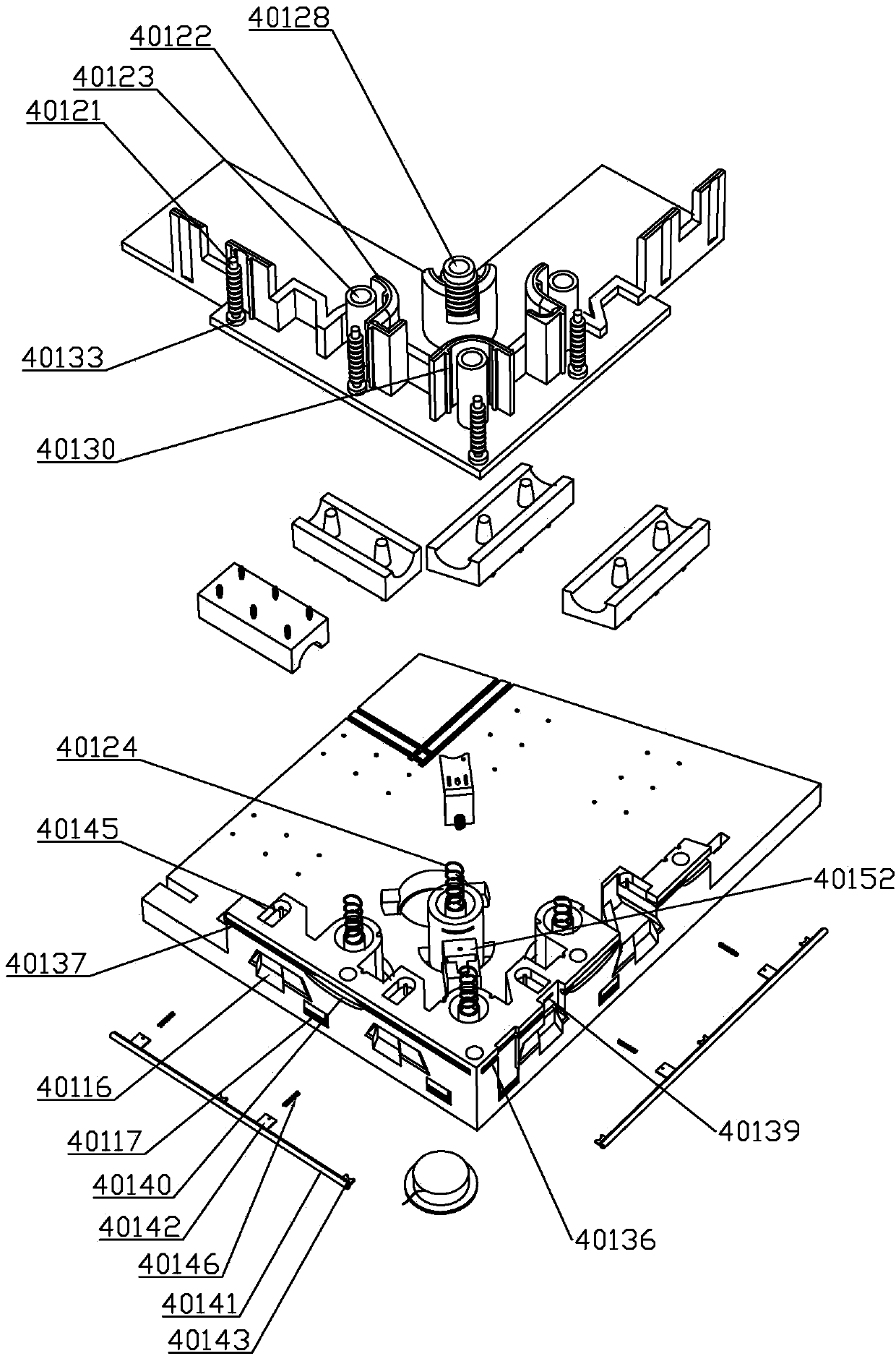

[0049] Such as figure 1 As shown, a prefabricated decoration suspended ceiling disclosed by the present invention includes a first-level suspended ceiling and a second-level suspended ceiling. The first-level suspended ceiling includes a suspended ceiling plate 1 (which can be an arc plate or a flat plate) fixedly connected to the ceiling. The size of the plate 1 is smaller than the size of the ceiling 2; the secondary suspended ceiling includes several grid telescopic modules 3 located under the ceiling plate 1, the grid telescopic modules 3 are arranged on the vertical wall panel 5 through the support module 4, and the grid telescopic modules 3 The width is greater than the distance between the edge of the ceiling board 1 and the vertical wall panel 5, and an adjustable intermediate module 6 is also provided on the grid telescopic module 3; the grid telescopic module 3, the support module 4 and the middle module 6 are located on the same horizontal plane, The bottom surface ...

Embodiment 2

[0076] Such as Figure 13 and Figure 14 As shown, the difference between this embodiment and embodiment 1 is:

[0077] The grid expansion module 3 corresponding to the window position has a gap, and the curtain box module includes side hanging top hanging blocks 804 (only one is drawn in the accompanying drawings) that are located at the two ends of the gap, and between the two side hanging top hanging blocks 804 The front panel 802 and the top panel 803 constitute a traditional curtain box; the side hanging top hanging block 804 is provided with a side hanging piece groove 80401, and the side hanging piece groove 80401 is provided with a hanging piece mother piece 80102 through screws, and the vertical wall panel 5 is provided with a Pendant female piece 80102 matched with pendant male piece 80103, side hanging top hanging block 804 is equipped with top hanging piece accommodation groove 80104 and top pendant mother piece barb protruding stick accommodation groove 80105, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com