Controller system and vacuum pump

A controller and vacuum pump technology, applied in pump control, pump testing, pump components, etc., to solve problems such as vacuum pumps not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

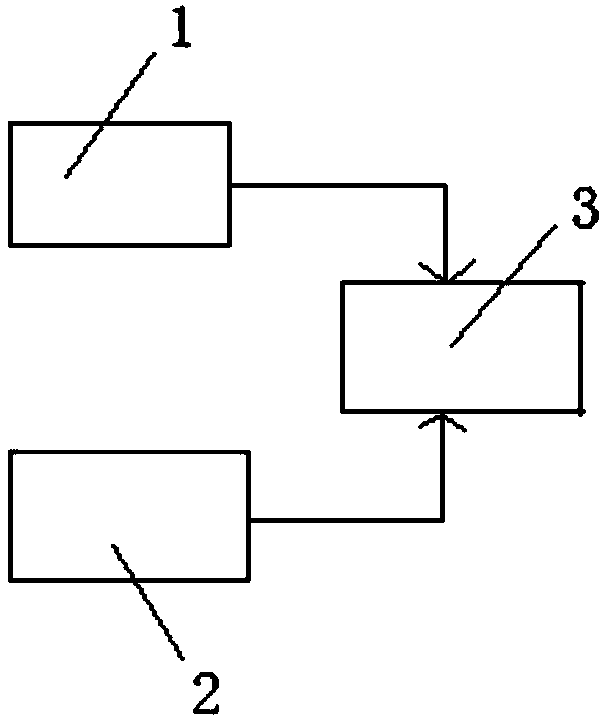

[0038] like figure 1 As shown, the present invention discloses a controller system, wherein the controller system includes an absolute pressure sensor 1 , a relative pressure sensor 2 and a controller 3 .

[0039] The absolute pressure sensor 1 can detect the altitude of the environment. The absolute pressure sensor 1 communicates with the atmosphere of the environment and can detect the pressure value of the environment. According to the detected pressure value, the pressure value signal can be converted into the corresponding pressure value by the conversion device. altitude signal. The absolute pressure sensor 1 can be a piezoresistive absolute pressure sensor 1 or a capacitive absolute pressure sensor 1 .

[0040] The relative pressure sensor 2 can detect the pressure value inside the vacuum pump.

[0041] Both the absolute pressure sensor 1 and the relative pressure sensor 2 are connected to the signal of the controller 3, and the controller 3 is connected to the signal...

Embodiment 2

[0044] In the second embodiment provided by the present invention, the structure of the controller system in this embodiment is similar to that in the first embodiment, and the similarities will not be repeated, and only the differences will be introduced.

[0045] In this embodiment, it is specifically disclosed that when the absolute pressure sensor 1 detects that the altitude is less than or equal to the first preset height value, the relative pressure sensor 2 detects that the pressure value is greater than or equal to the first opening pressure value and less than the first Stopping the pressure value, the controller 3 can control the vacuum pump to turn on, and when the relative pressure sensor 2 detects that the pressure value is greater than or equal to the first stop pressure value, the controller 3 can control the vacuum pump to turn off.

[0046] When the absolute pressure sensor 1 detects that the altitude is greater than the first preset height value and less than ...

Embodiment 3

[0058] The present invention discloses a vacuum pump, including the controller system described in any one of the above embodiments.

[0059] Since the vacuum pump provided by the present invention includes the controller system in any one of the above embodiments, the beneficial effects of the controller system are included in the vacuum pump disclosed in the present invention.

[0060] In the present invention, "first", "second", etc. are for distinction in description, and have no other special meanings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com