Hydraulic torque converter with reversing dragging function

A hydraulic torque converter and functional technology, applied in the field of mechanical design, can solve problems such as difficulty in starting, and achieve the effects of expanding functions, increasing fuel economy, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

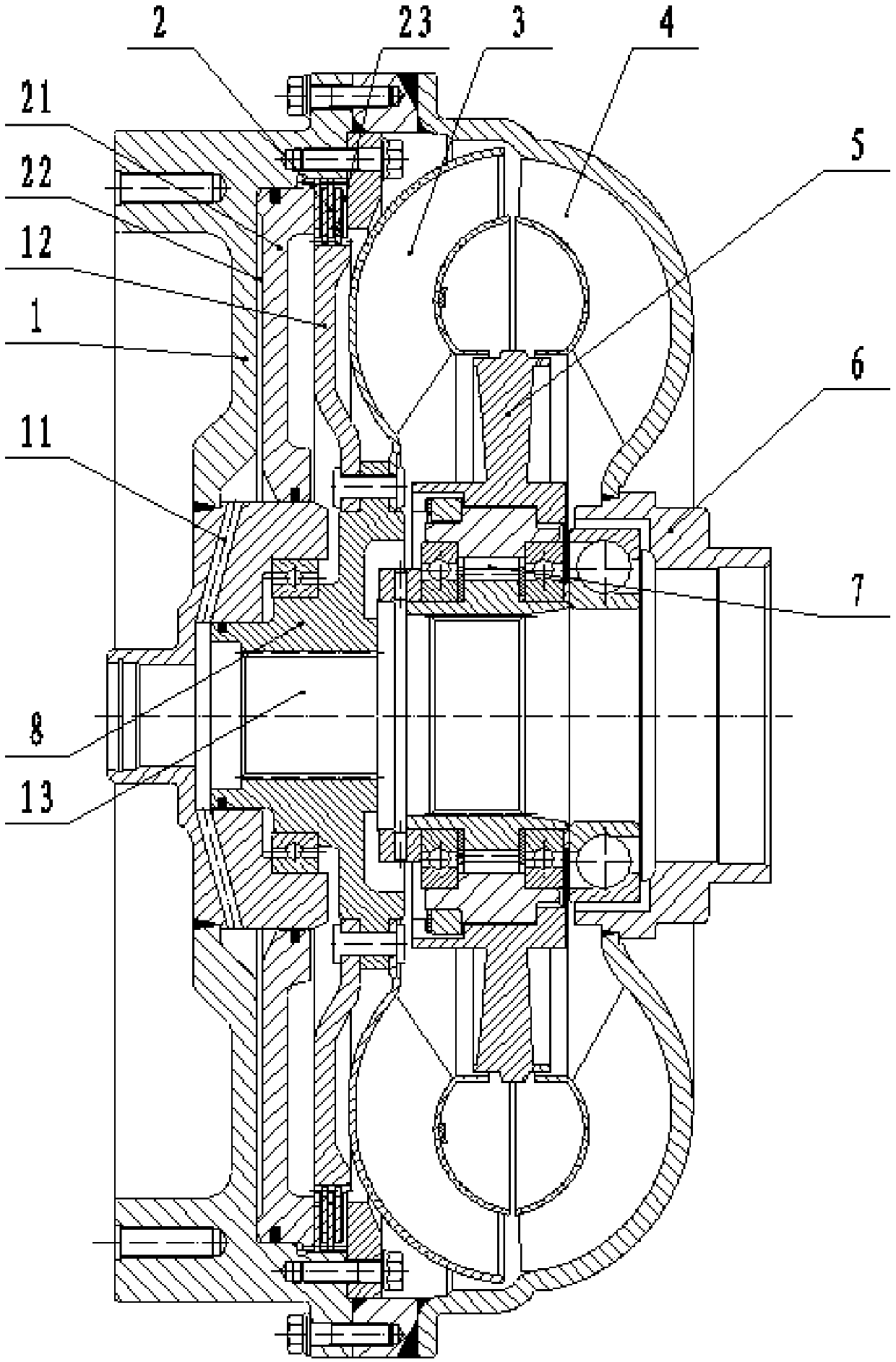

Embodiment 1

[0025] see figure 2 , the hydraulic torque converter of this embodiment is in figure 1 An anti-drag device is added to the structure of the conventional torque converter with a lock-up clutch, specifically, an anti-drag device consisting of an anti-drag inner ring 9 and a second one-way clutch 10 is added inside the cover wheel 1; The inner ring 9 is arranged on the output shaft of the conventional hydraulic torque converter; the end of the outer wall of the anti-drag inner ring 9 away from the cover wheel 1 is splined to the turbine hub 8, and the middle part of the outer wall of the anti-drag inner ring 9 is connected to the second unit It is fixedly connected to the inner ring of the clutch 10; the outer ring of the second one-way clutch 10 is fixedly connected to the cover wheel 1; when the power is input from the output shaft, the second one-way clutch 10 is in a locked state; When inputting, the second one-way clutch 10 is in an overrunning state. The second one-way c...

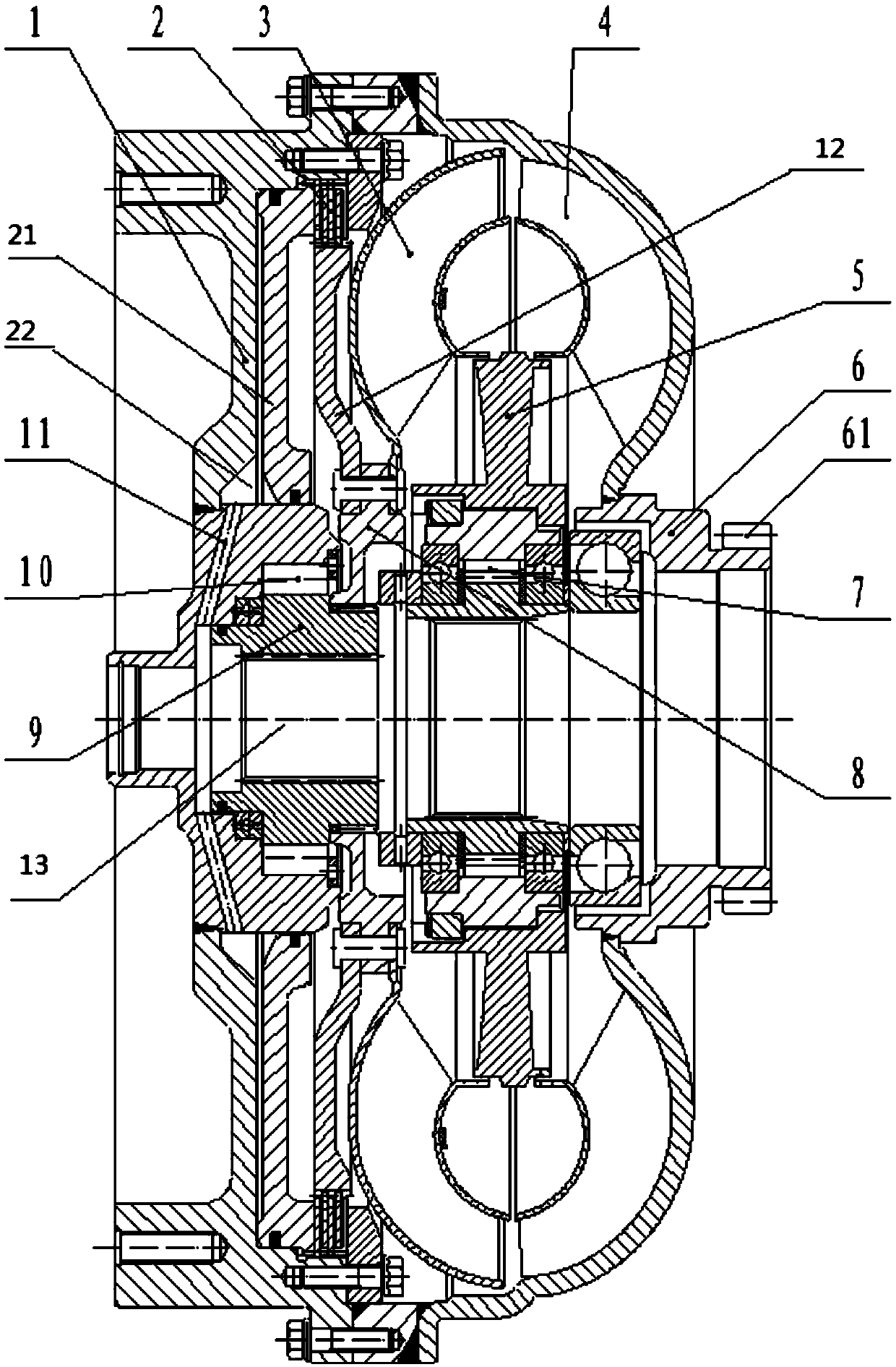

Embodiment 2

[0035] see image 3 In this embodiment, an anti-drag device is added to the structure of a traditional hydraulic torque converter without a lock-up clutch. The difference from Embodiment 1 is that the lock-up clutch 2 and the torque converter lock-up oil passage 11 are omitted in this embodiment. The hydraulic torque converter of this embodiment can work in the following working conditions:

[0036] 1. Hydraulic working condition

[0037] When the vehicle starts and climbs, the hydraulic torque converter works in the hydraulic condition, at this time the second one-way clutch 10 is opened (in the overrunning state), and the power transmission route is: cover wheel 1→pump wheel 4→turbine 3 →turbine hub 8→anti-drag inner ring 9→output shaft 13.

[0038] 2. Anti-drag working condition

[0039] After the vehicle has been stationary for a long time in a low temperature environment, it is difficult to start the vehicle due to the relatively low ambient temperature and the relativ...

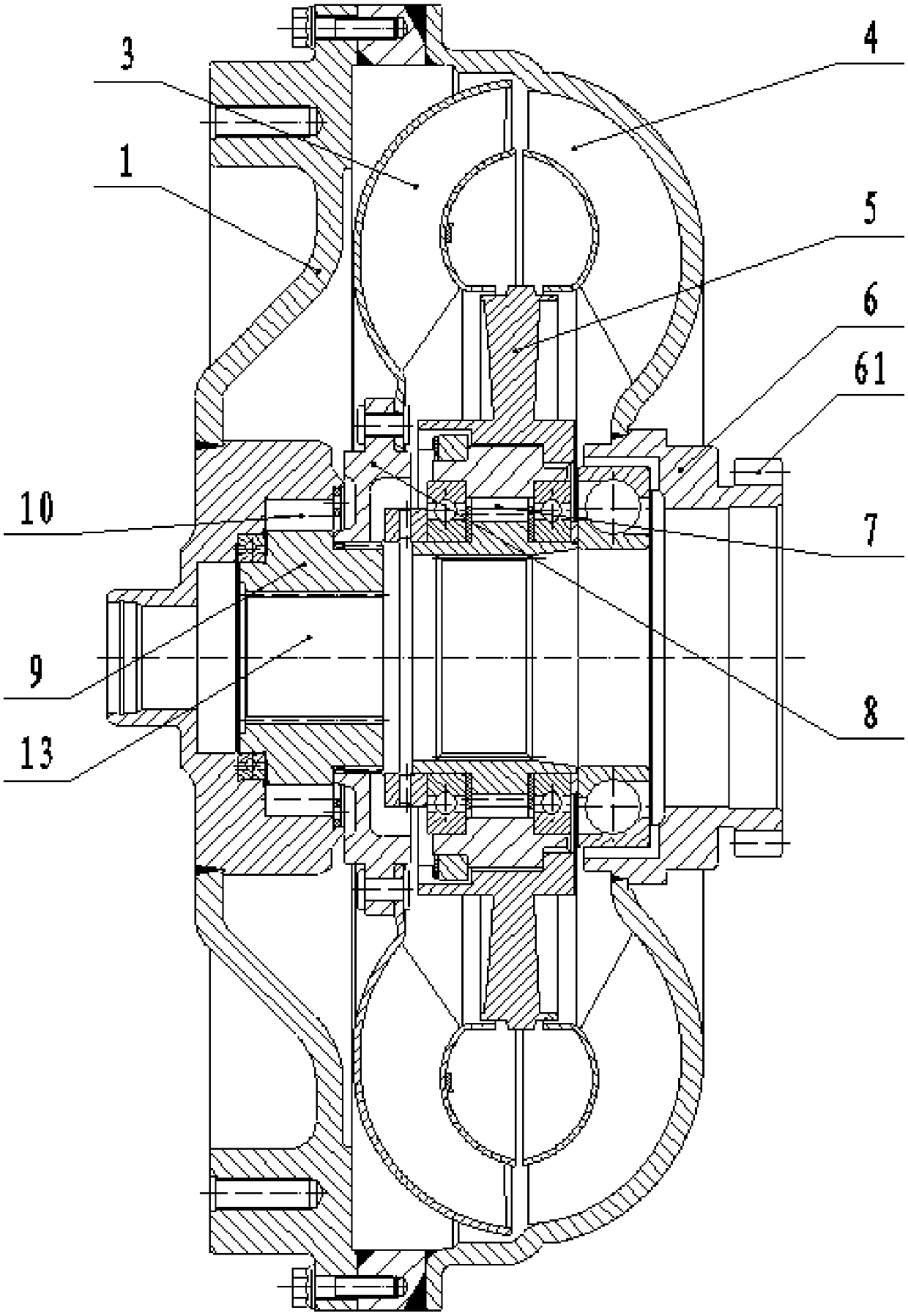

Embodiment 3

[0042] This embodiment is based on the structure of Embodiment 1 or 2, and a power take-off gear 61 is set on the pump hub 6. When the vehicle is stationary, the engine is started. Full power power is taken at 61, and the power transmission route is: cover wheel 1→pump wheel 4→pump hub 6→power take-off gear 61. All the other working conditions are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com