Quick coupling male component capable of automatically relieving pressure

An automatic unloading and male head technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of large structural restrictions, unstable supply pressure, bulges, etc., to improve stability and reliability, and reduce swelling and damage , the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

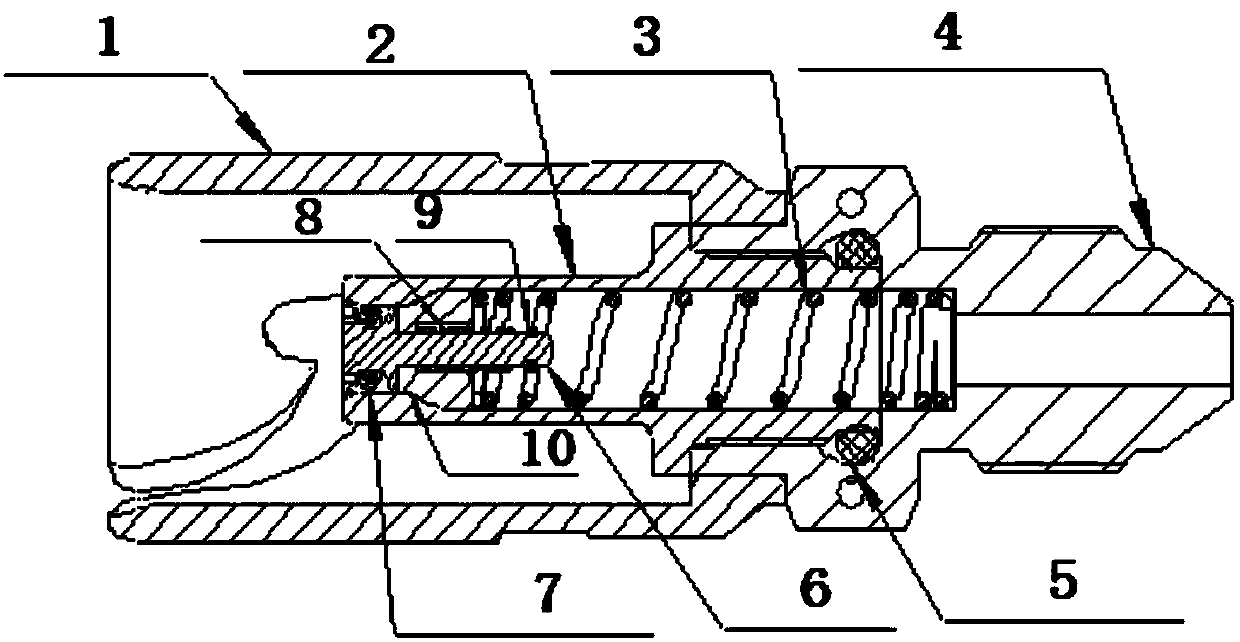

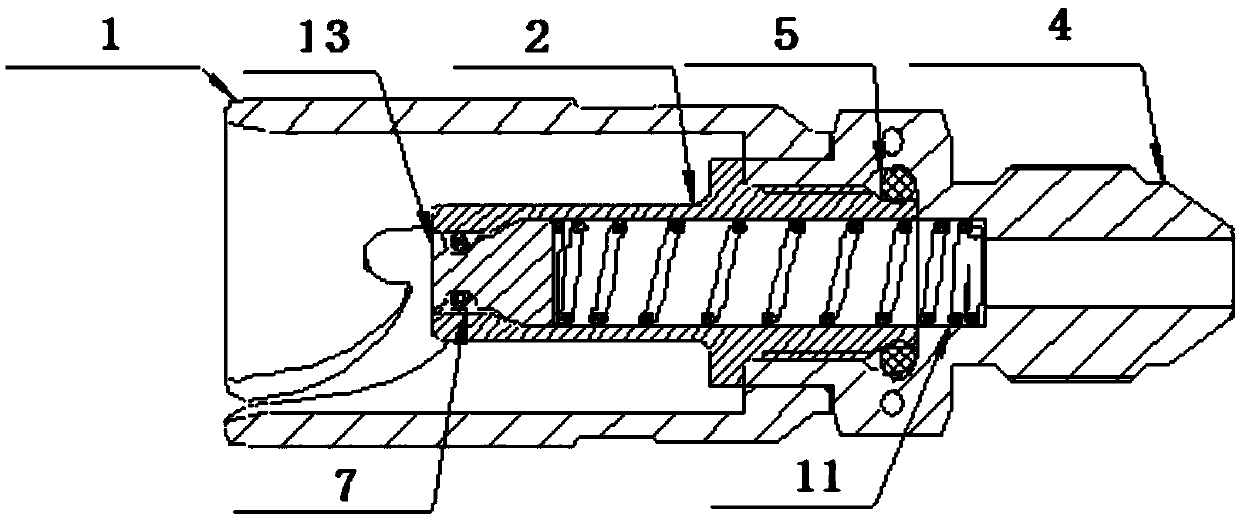

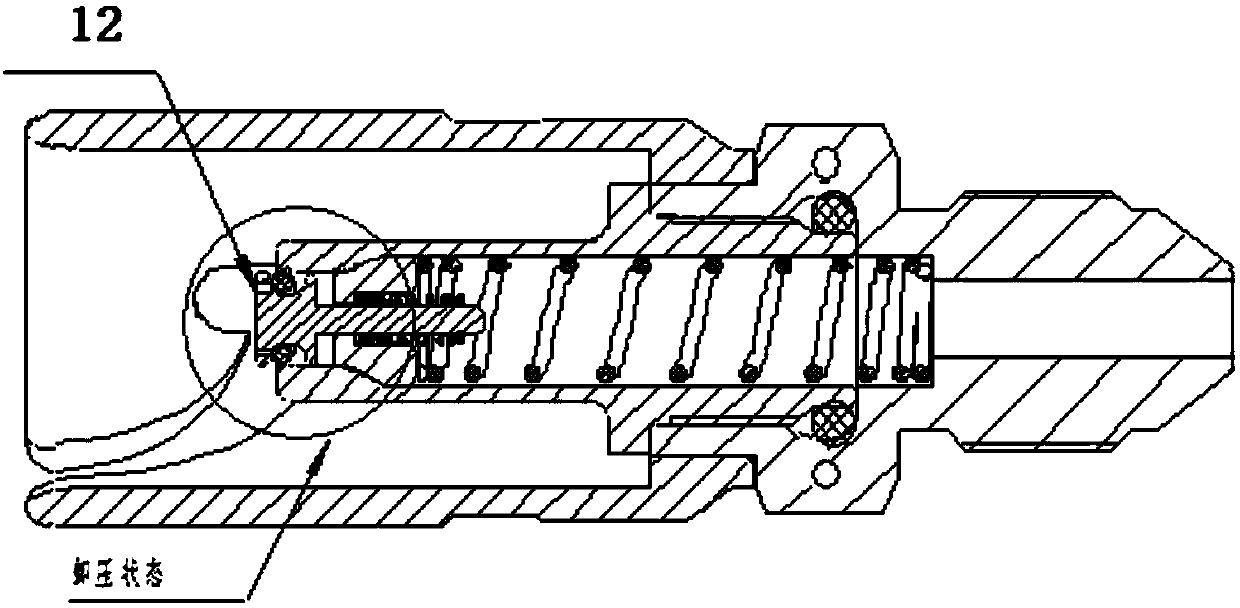

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The inventive idea of the present invention is as follows: when the internal space pressure formed by the quick connector male assembly and the module is lower than the pressure value P1, the quick connector male assembly realizes the self-sealing function; when the internal space pressure formed by the quick connector male assembly and the module When the value is higher than P1 and smaller than P2, the quick connector male assembly will automatically release the pressure to discharge the internal pressure to protect the module from being exploded by the sharply increased pressure; when the internal pressure of the module drops to P3 after the pressure is discharged, the pressure relief will be closed , The quick connector male head assembly re-realizes the self-sealing function. Among them, 0~P1 is the self-sealing work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com