Air tightness testing equipment for canned food

A technology for air tightness detection and canned food, which is used in liquid/vacuum measurement for liquid tightness, fluid tightness test, and machine/structural component testing, etc. Achieve the effect of improving quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

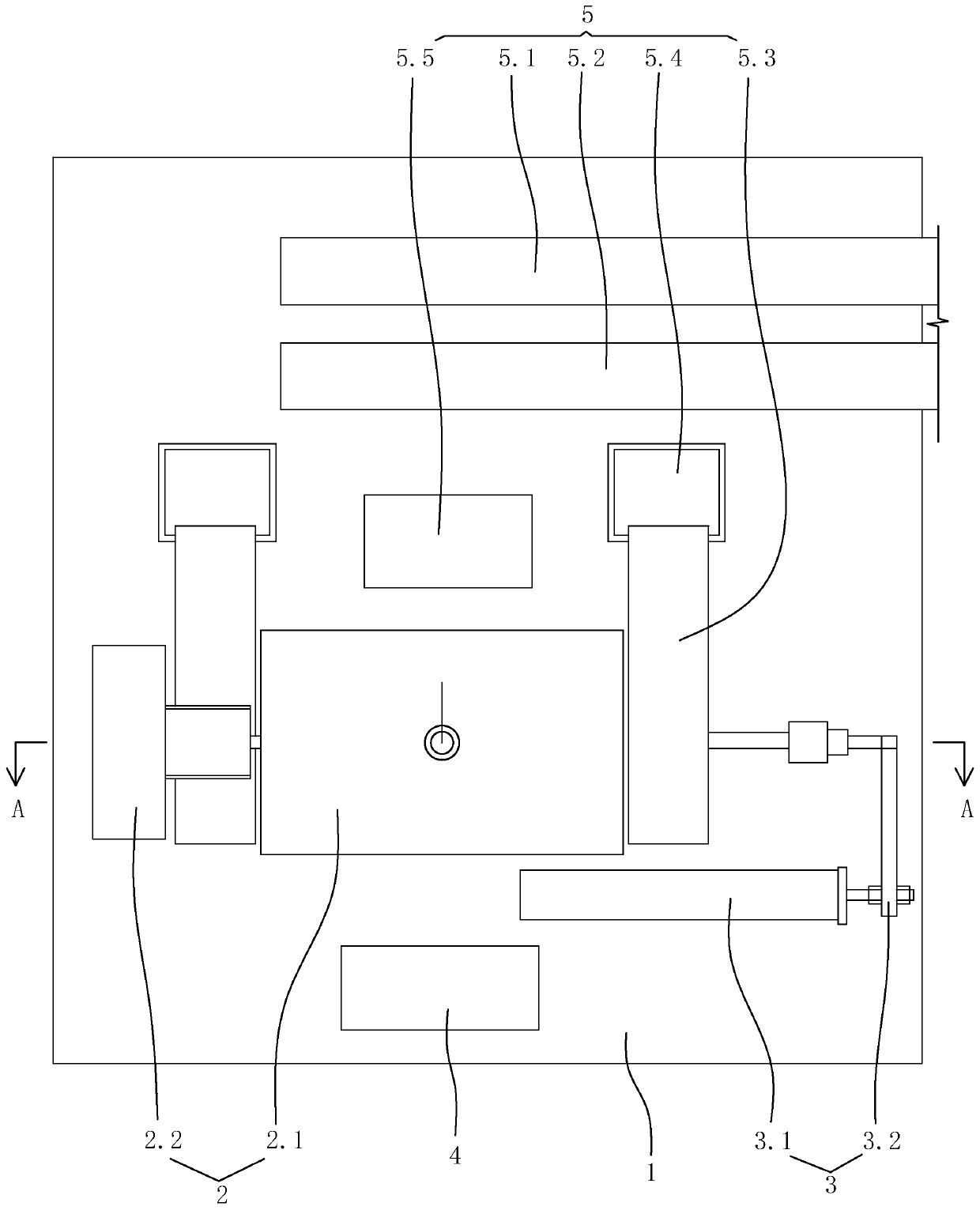

[0025] Such as figure 1 Shown, a kind of airtightness detection equipment of canned food, comprises frame 1, booster pump, connecting pipe, the airtightness detection device 2 that is arranged on the frame, feeding manipulator 4, and is arranged on the frame The canned food output mechanism 5 on the top.

[0026] The airtightness detection device is used to detect the airtightness of canned food.

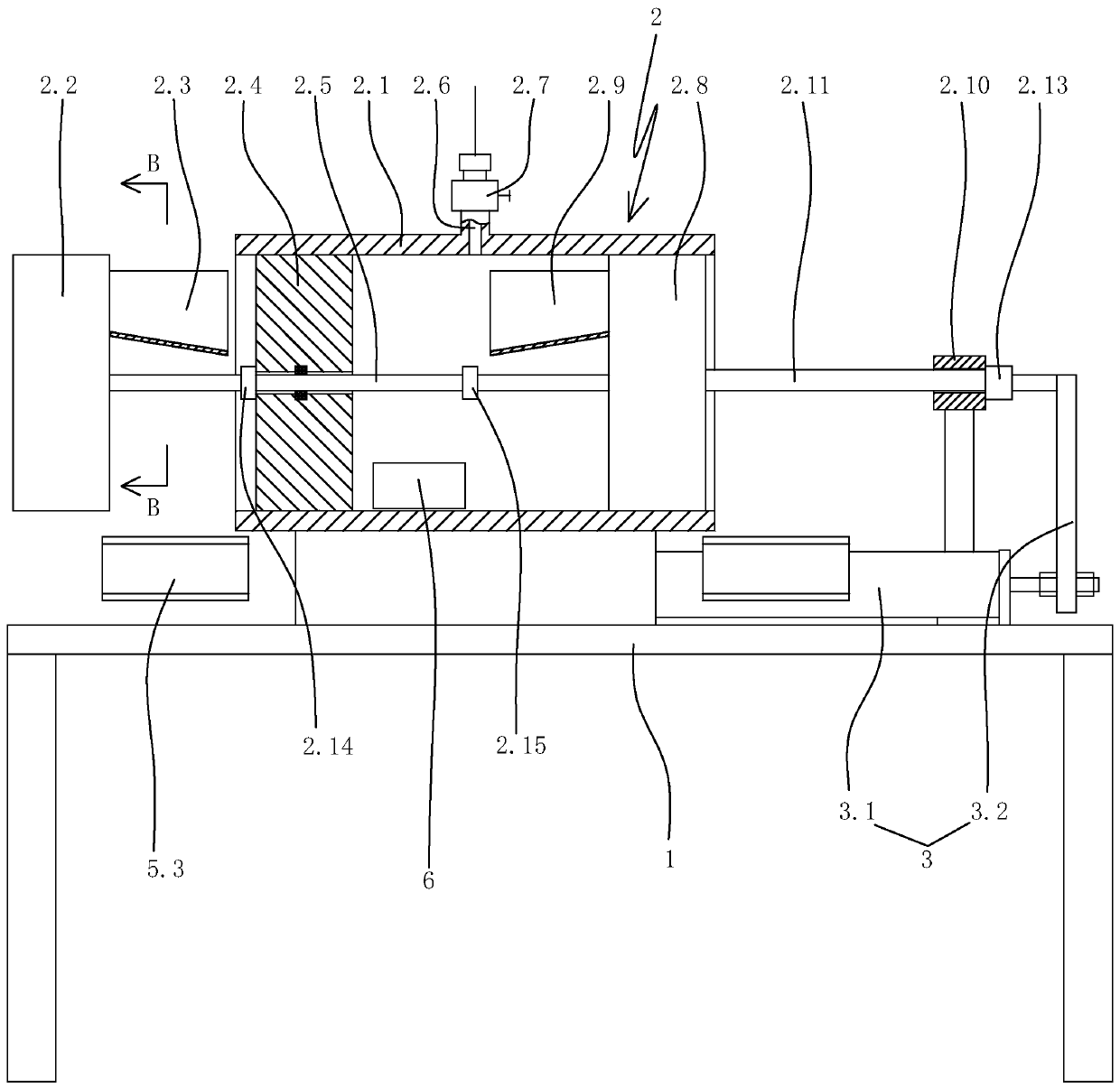

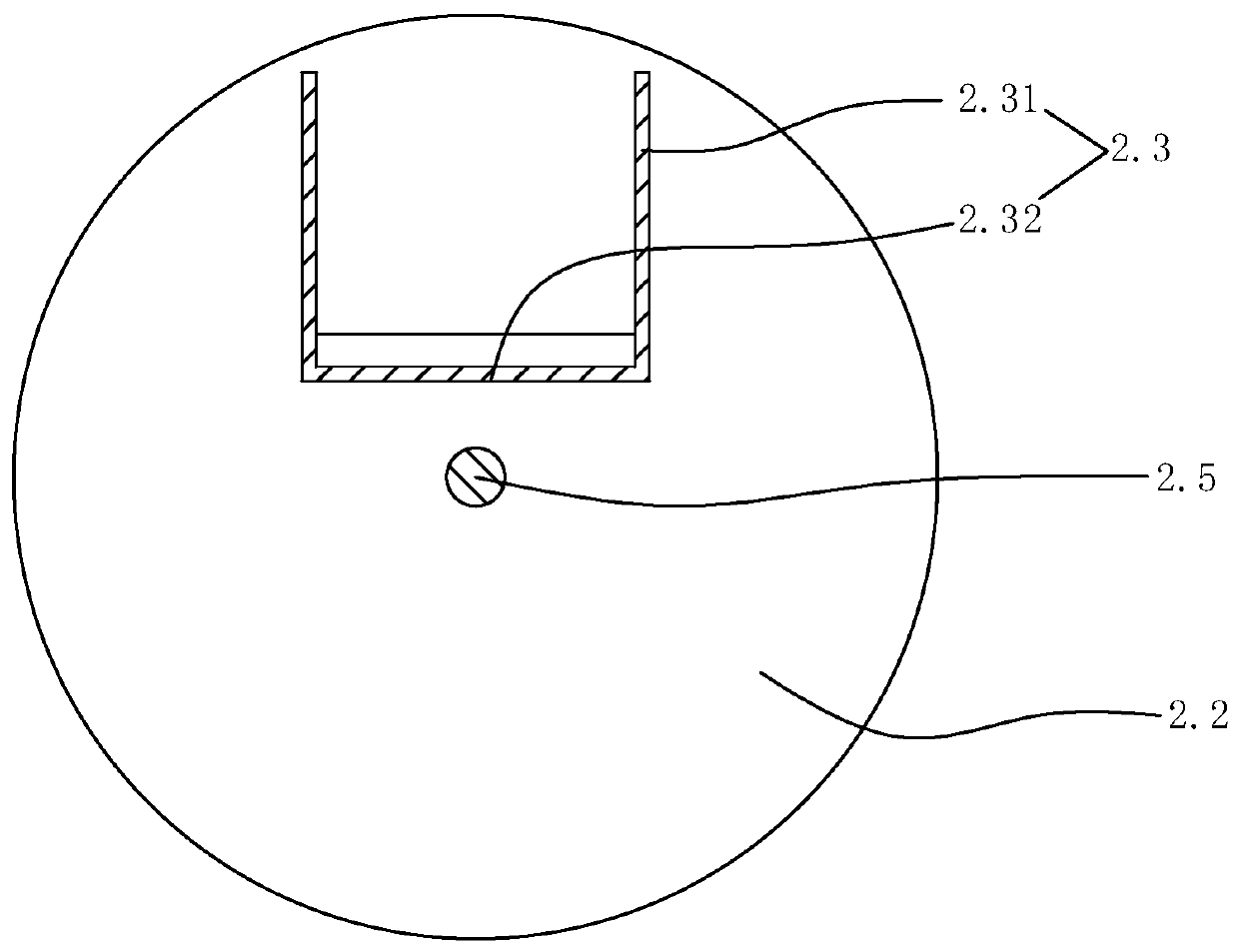

[0027] Such as figure 1 , figure 2 As shown, the air tightness detection device includes a horizontal cylinder 2.1 with openings at both ends arranged on the frame, a left piston 2.2 slidingly matched with the horizontal cylinder, a floating piston 2.4 slidingly matched with the horizontal cylinder, and a horizontal cylinder 2.4 slidingly matched with the horizontal cylinder. body sliding fit right piston 2.8, connecting shaft rod 2.5 connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com