A Method for Detecting Air Leakage Points of Multilayer Vacuum Bag Films Using Oxygen Sensitive Substances

An oxygen-sensitive, vacuum bag technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of not being able to accurately find the leak point of the vacuum bag film, and achieve overall The length of the process and the difficulty of process control are moderate, saving manpower and material resources, and ensuring the effect of molding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

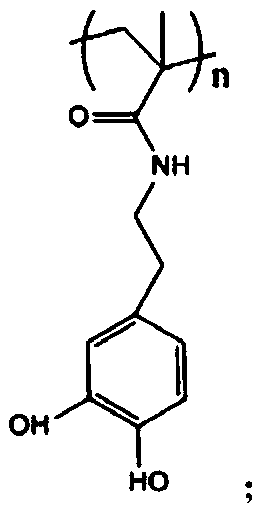

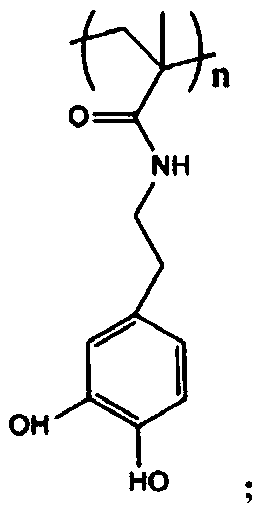

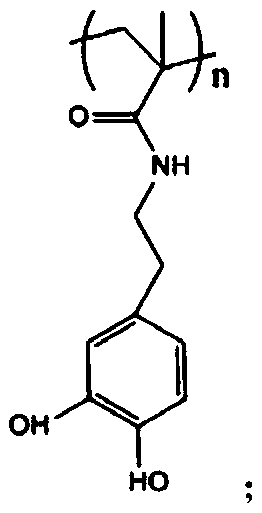

Embodiment 1

[0026] A method for detecting the air leakage point of a three-layer vacuum bag film by using an oxygen-sensitive substance. Under the condition of filling inert gas nitrogen protection, the catechol compound and the pellets of the vacuum bag film are first melted and blended to obtain pellets. Then, the pellets of the vacuum bag film and the pellets obtained by melt blending are co-extruded in three layers, so that the catechol compounds that will change color after encountering air are evenly dispersed in the three-layer vacuum bag film. The second layer, then put the three-layer vacuum bag film in the air, observe the vacuum bag film, the point where the observed color changes is the air leakage point, the color change is within the range visible to the naked eye, from colorless to pink, Turn into black at last, and wherein the second layer of vacuum bag film is the interlayer of thickness 10 μ m, and the content in the catechol compound in the interlayer is 0.1wt%, and ther...

Embodiment 2

[0030] A method for detecting the air leakage point of a five-layer vacuum bag film by using an oxygen-sensitive substance. Under the condition of filling inert gas argon for protection, the catechol compound and the pellets of the vacuum bag film are firstly melted and blended to obtain Granules, and then five-layer co-extrusion composite of the pellets of the vacuum bag film and the pellets obtained by melt blending, so that the catechol compounds that will change color after encountering air are evenly dispersed in the five-layer vacuum bag film Then put the five-layer vacuum bag film in the air, observe the vacuum bag film, the point where the observed color changes is the air leakage point, and the color change is within the range visible to the naked eye, from colorless to pink , and finally turn black, wherein the third layer of the vacuum bag film is an interlayer with a thickness of 30 μm, and the content of catechol compounds in the interlayer is 10wt%, and there is a...

Embodiment 3

[0034] A method for detecting the air leakage point of a four-layer vacuum bag film by using oxygen-sensitive substances. Under the condition of filling inert gas helium protection, the catechol compound and the pellets of the vacuum bag film are first melted and blended to obtain Granules, and then four-layer co-extrusion compounding of the pellets of the vacuum bag film and the pellets obtained by melt blending, so that the catechol compounds that will change color after encountering air are evenly dispersed in the four-layer vacuum bag film The second and third layers, and then put the four-layer vacuum bag film in the air, observe the vacuum bag film, the point where the observed color changes is the air leakage point, and the color change is within the range visible to the naked eye. The color turns pink and finally black, wherein the second and third layers of the vacuum bag film are interlayers with a thickness of 20 μm, and the content of catechol compounds in the inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com