A kind of ru-moo3-x/rgo composite material and its preparation method and application

A technology of ru-moo3-x and composite materials, applied in the field of nanomaterials, can solve the problems of easy aggregation of active components, decreased activity, high overpotential, etc., and achieve the effect of increasing O vacancy content, simple process, and excellent HER performance

Inactive Publication Date: 2019-05-14

武汉言诺嘉科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of designing fuel cells, there are still some problems that need to be solved urgently: first, in the process of electrolysis of water, the overpotential of the hydrogen evolution reaction (HER) that occurs at the cathode of the fuel cell is relatively high; , the active components are easy to agglomerate, resulting in a decrease in activity

At the same time, there are few reports on optimizing the hydrogen evolution reaction (HER) by adjusting the content of surface O vacancies in metal oxides.

In particular, the introduction of active metal Ru to adjust the content of O vacancies to optimize the catalytic performance has not been reported yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

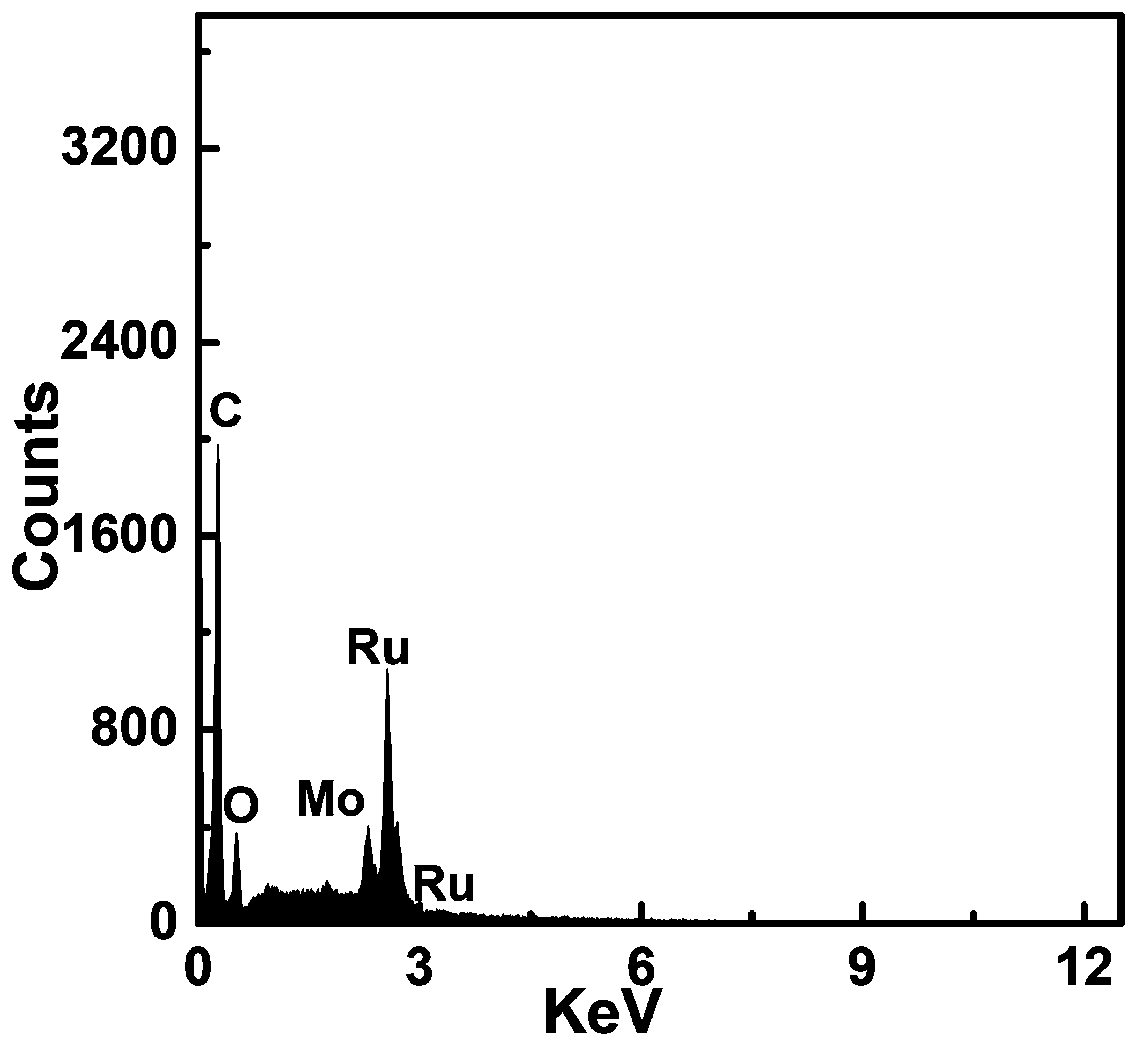

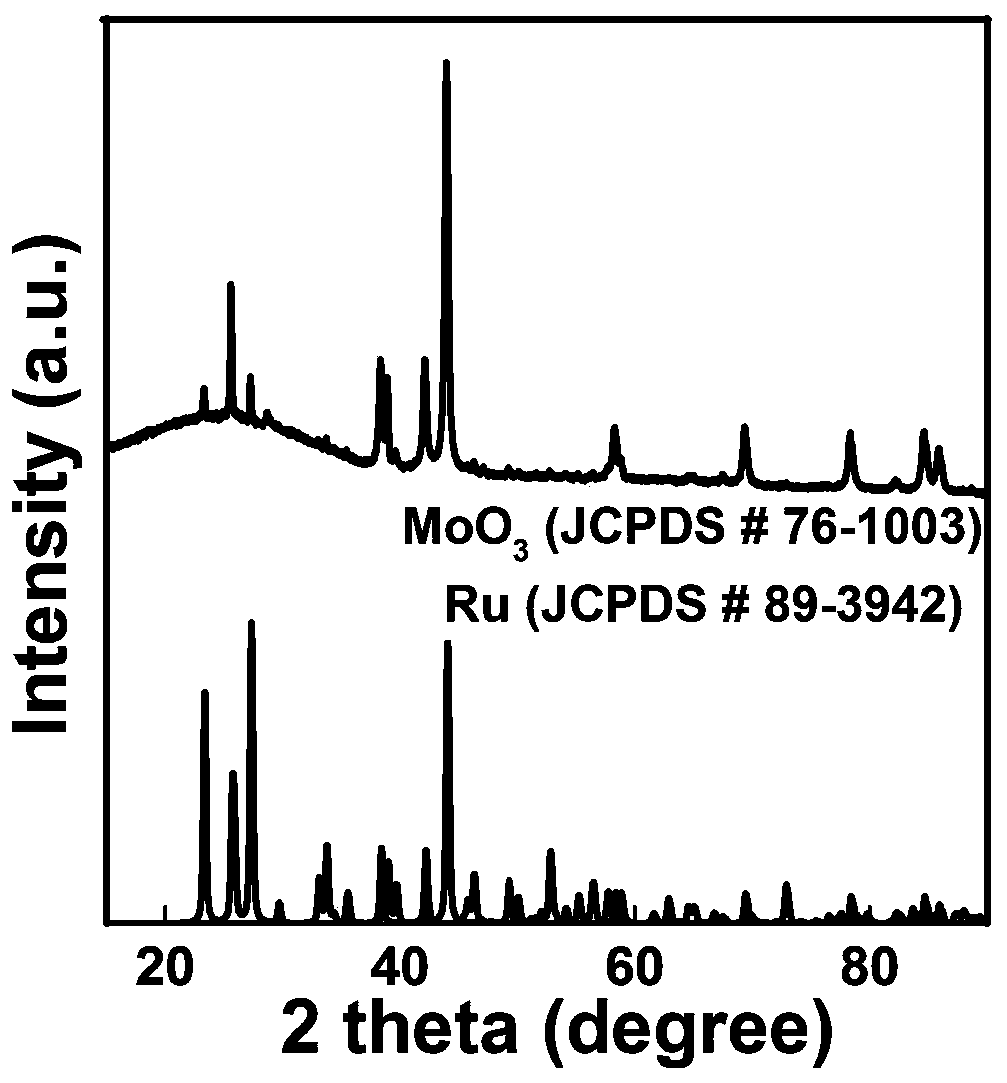

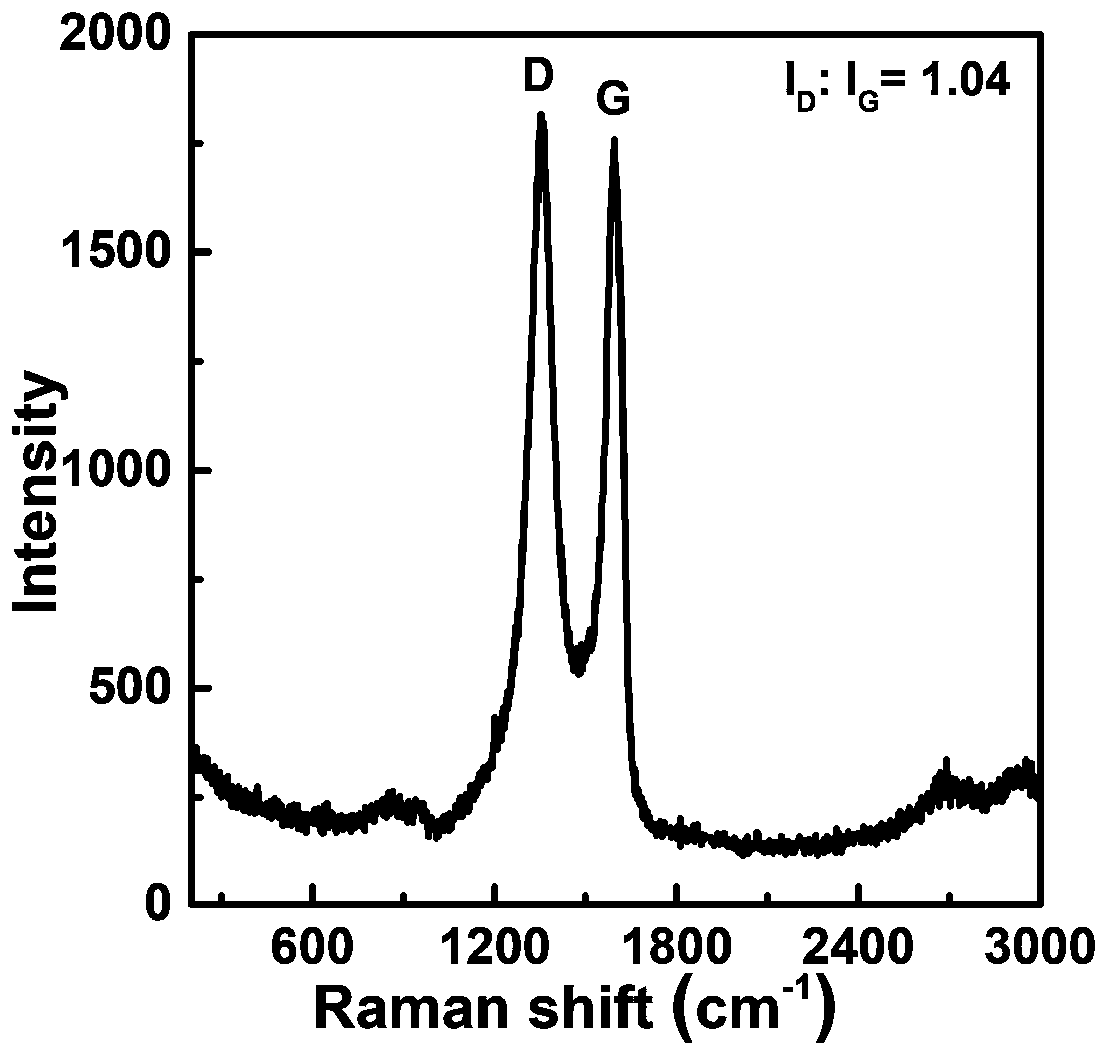

[0031] The Ru-MoO of this embodiment 3-x / rGO composites including rGO substrate with Ru-MoO on rGO substrate 3-x Nanocrystalline, Ru-MoO 3-x Nanocrystals including uniformly composited Ru and MoO 3-x , Ru uniformly decorated in MoO 3-x Surface, where x ranges from 0 to 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a Ru-MoO<3-x> / rGO composite material. The Ru-MoO<3-x> / rGO composite material comprises an rGO substrate, wherein the rGO substrate is provided with a Ru-MoO<3-x> nano-crystal;the Ru-MoO<3-x> nano-crystal comprises Ru and MoO<3-x> which are uniformly compounded; the Ru is uniformly modified on the surface of the MoO<3-x>, wherein the value of x ranges from 0 to 3. The Ru-MoO<3-x> / rGO composite material disclosed by the invention has excellent HER (Hydrogen Evolution Reaction) performance; HER in fuel cells can be efficiently catalyzed and the Ru-MoO<3-x> / rGO composite material is prepared through an in-situ growth self-assembling method; the Ru-MoO<3-x> / rGO composite material is controllably synthesized under normal pressure; meanwhile, a self-assembling manner is adopted so that the a technology is simple and is suitable for batch production.

Description

technical field [0001] The invention relates to a Ru-containing composite material, more specifically to a Ru-MoO 3-x The / rGO composite material and its preparation method and application belong to the technical field of nanometer materials. Background technique [0002] With the development of society, people's demand for energy is increasing, and the search and development of sustainable and efficient clean energy to replace limited fossil fuels has attracted global attention. In recent years, the development and utilization of fuel cells has further broadened the scope of research in the field of energy. However, in the process of designing fuel cells, there are still some problems that need to be solved urgently: first, in the process of electrolysis of water, the overpotential of the hydrogen evolution reaction (HER) in the cathode of the fuel cell is relatively high; , the active components are easy to agglomerate, resulting in a decrease in activity. Studies have ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/90H01M4/88

CPCH01M4/88H01M4/9016H01M4/9083Y02E60/50

Inventor 刘苏莉刘光祥陈成郑秋慧张苏迪陈昌云顾祥耀

Owner 武汉言诺嘉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com