Molybdenum disulfide catalyst with adjustable phase composition and large interlayer spacing as well as preparation method and application of molybdenum disulfide catalyst

A molybdenum disulfide and catalyst technology, applied in the fields of electrocatalysis and material science, to achieve the effect of mature synthesis process, optimized hydrogen adsorption and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

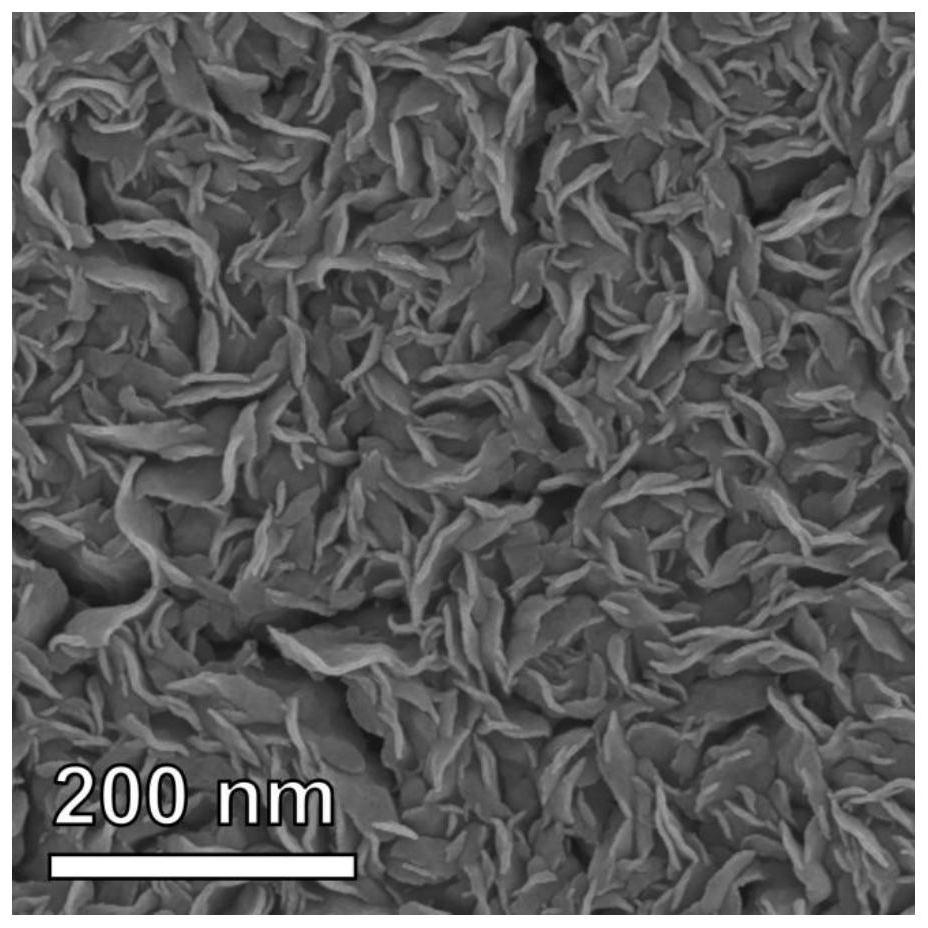

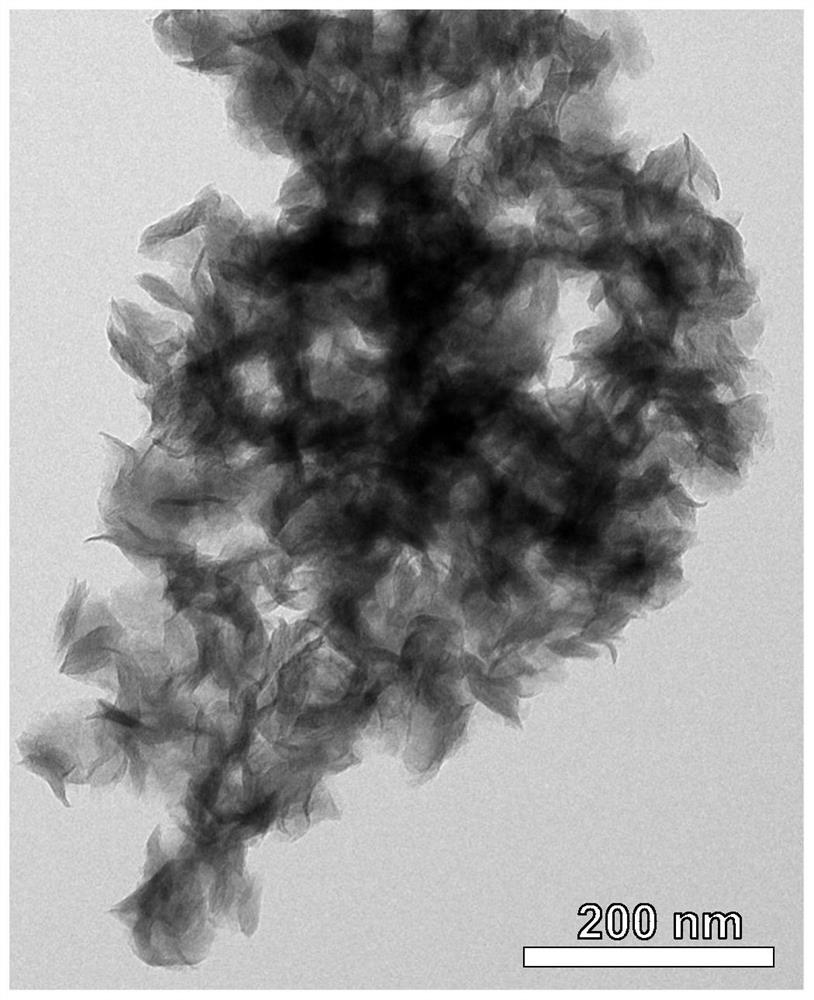

[0034] This embodiment provides a molybdenum disulfide catalyst with an adjustable phase composition and a large interlayer spacing and its preparation method and application, including the following steps:

[0035] (1) Pretreatment of carbon fiber paper (CFP): Carefully ultrasonically clean CFP (2×5cm) with absolute ethanol, hydrochloric acid, and deionized water 2 ), to remove impurities on the surface, first place the CFP in absolute ethanol for 3 minutes of ultrasonic treatment, take it out and rinse it repeatedly with deionized water; ; Then place it in an oven at 80°C for 60 minutes;

[0036] (2) Preparation of the reaction solution: the solute Na 2 MoO 4 (0.19g) and TAA (0.3g) are placed in 50 milliliter beakers, then add the mixed solution of 40 milliliters of deionized water and absolute ethanol as solvent, wherein the volume ratio of deionized water and absolute ethanol is 1:2, Stir at room temperature for 30 minutes under the action of magnetic force until comple...

Embodiment 2

[0042] This embodiment provides a molybdenum disulfide catalyst with an adjustable phase composition and a large interlayer spacing and its preparation method and application, including the following steps:

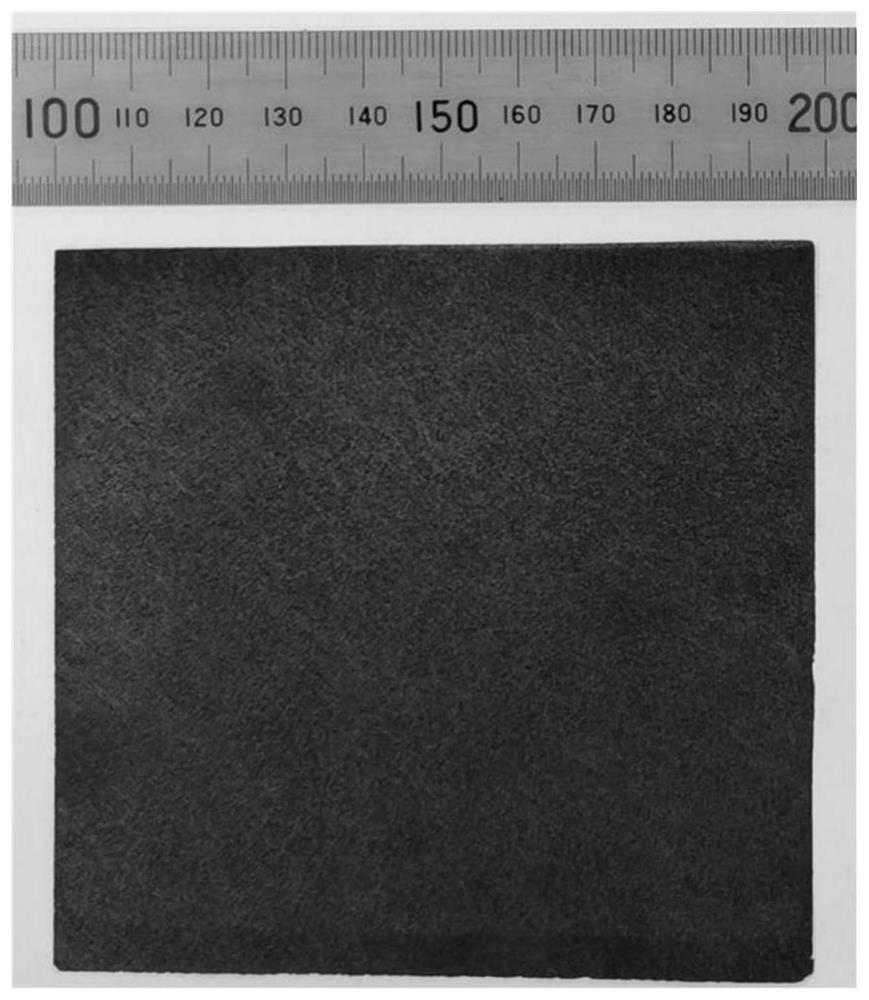

[0043] (1) Pretreatment of carbon fiber paper (CFP): Carefully ultrasonically clean CFP (10×10cm 2 ), to remove impurities on the surface, first place the CFP in absolute ethanol for 3 minutes of ultrasonic treatment, take it out and rinse it repeatedly with deionized water; ; Then place it in an oven at 80°C for 60 minutes;

[0044] (2) Preparation of the reaction solution: the solute Na 2 MoO 4 (0.19g) and TAA (0.3g) are placed in 50 milliliters of beakers, then add the mixed solution of 40 milliliters of deionized water and absolute ethanol as solvent, wherein the volume ratio of deionized water and absolute ethanol is 2:3, Stir at room temperature for 30 minutes under the action of magnetic force until completely dissolved and uniform;

[0045] (3) Transfer the pr...

Embodiment 3

[0050] This embodiment provides a molybdenum disulfide catalyst with an adjustable phase composition and a large interlayer spacing and its preparation method and application, including the following steps:

[0051] (1) Pretreatment of carbon fiber paper (CFP): Carefully ultrasonically clean CFP (2×5cm) with absolute ethanol, hydrochloric acid, and deionized water 2 ), to remove impurities on the surface, first place the CFP in absolute ethanol for 3 minutes of ultrasonic treatment, take it out and rinse it repeatedly with deionized water; ; Then place it in an oven at 80°C for 60 minutes;

[0052] (2) Preparation of the reaction solution: the solute Na 2 MoO 4 (0.19g) and TAA (0.3g) are placed in 50 milliliters of beakers, then add the mixed solution of 40 milliliters of deionized water and absolute ethanol as solvent, wherein the volume ratio of deionized water and absolute ethanol is 2:1, Stir at room temperature for 30 minutes under the action of magnetic force until co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com