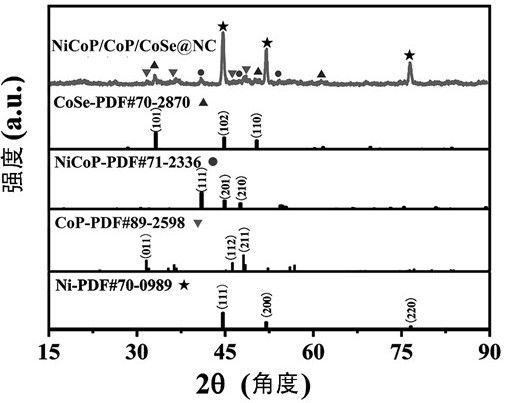

nicop/cop/cose@nc catalyst and preparation method

An electrocatalyst, nitrogen doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor performance, achieve fast electron transfer, good stability, overpotential low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0064] The nickel foam sheet is pretreated before use: cut the nickel foam sheet into 2×1 cm 2, then placed in a concentrated nitric acid solution with a mass concentration of 95%, ultrasonically treated for 15 min at 30 kHz, and then ultrasonically cleaned with water and ethanol for 6 times at 30 kHz, and vacuum dried at 50 ℃, -0.05MPa for 4h , get foam nickel sheet 1.

reference example 2

[0066] The nickel foam sheet is pretreated before use: cut the nickel foam sheet into 2×1 cm 2 , and then placed in a concentrated hydrochloric acid solution with a mass concentration of 36%, ultrasonically treated for 5 minutes at 20 kHz, then ultrasonically cleaned with water and ethanol for 8 times at 20 kHz, and vacuum dried at 40 ℃ and -0.08MPa for 5h , get foam nickel sheet 2.

reference example 3

[0068] The nickel foam sheet is pretreated before use: cut the nickel foam sheet into 2×1 cm 2 , and then placed in a concentrated nitric acid solution with a mass concentration of 95%, ultrasonically treated for 3 minutes at 40 kHz, and then ultrasonically cleaned with water and ethanol for 4 times at 40 kHz, and vacuum dried at 60 ° C and -0.03 MPa for 3 hours. , get foam nickel sheet 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com