Preparation method of fermented soybean sauce, and fermented soybean sauce

A production method and technology of fermented soy sauce, which is applied in the production of fermented bean sauce and the field of fermented bean sauce, can solve the problems of burnt, unfavorable eating, and affecting the taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

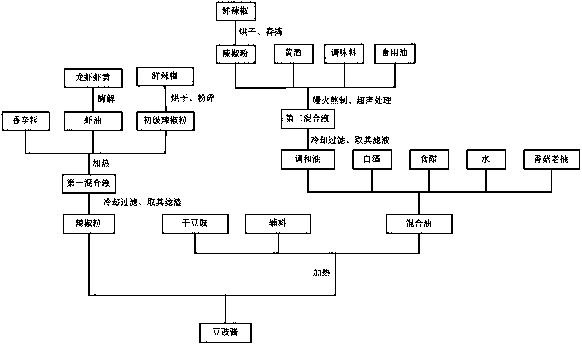

[0020] Such as figure 1 As shown, the present embodiment 1 provides a method for making fermented soy sauce, which includes the following steps: step S1, prepare chili powder; step S2, prepare mixed oil; and step S3, put dried fermented soy sauce and auxiliary materials into the mixed oil and heat Afterwards, put the chili granules and refrigerate.

[0021] Wherein, the components by weight of the fermented soy sauce include: 400-500 parts of dried tempeh, 300-350 parts of mixed oil, 25-40 parts of capsicum granules, and 20-50 parts of auxiliary materials. Among them, the ratio of dry fermented soya bean to mixed oil can be used to adjust the thin consistency of fermented soya bean sauce.

[0022] The preparation method of fermented soya bean sauce in this embodiment 1 separates dried fermented soya beans and chili granules, and puts chili granules after heating the dried fermented soya beans, auxiliary materials and mixed oil. It can keep the chewiness and the original spic...

Embodiment 2

[0049] On the basis of Example 1, this Example 2 provides a fermented soy sauce, including: dried fermented soya bean, chili granules, auxiliary materials, and mixed oil; wherein the dried fermented soya bean and auxiliary materials are suitable for heating in the mixed oil, and Add chili flakes and refrigerate.

[0050] For the specific ingredients and production process of chili grains, auxiliary materials and mixed oil, please refer to the relevant discussion of Example 1, and will not repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com