Making method of chilli oil and chilli oil

A production method and technology of chili oil, applied in edible oil/fat, food science, application, etc., can solve the problems of high cost, burning, affecting the chewiness and spicy feeling of chili grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

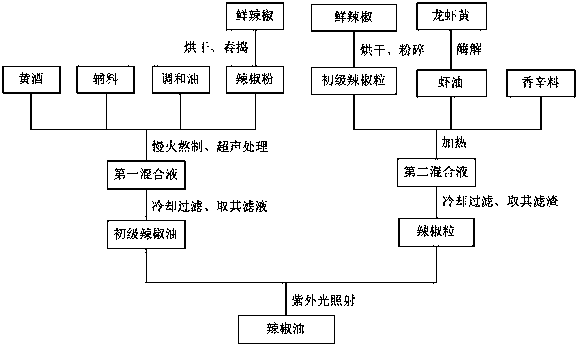

[0020] Such as figure 1 As shown, the present embodiment 1 provides a preparation method of chili oil, including the following steps: step S1, preparing primary chili oil; step S2, preparing chili grains; and step S3, mixing chili grains and primary chili oil.

[0021] The preparation method of the chili oil in Example 1 is prepared by separating the primary chili oil from the chili grains, so that the primary chili oil is full of the spicy taste of the chili pepper, while the chili grains retain the chewiness and original spicy feeling.

[0022] As an optional implementation of the method for preparing primary chili oil.

[0023] See figure 1 The method for preparing primary chili oil in step S1 includes the following steps: step S11, selecting fresh chili to dry until the water content is lower than 5% and pounding to make chili powder; step S12, making the chili powder, A small amount of rice wine and auxiliary materials are put into the blended oil and boiled slowly; ste...

Embodiment 2

[0048] On the basis of Example 1, this Example 2 provides a chili oil, including: chili grains and primary chili oil.

[0049] For the specific ingredients and production process of the capsicum granules and primary capsicum oil, refer to the relevant discussion of Example 1, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com