Processing method of flavored crawfish-tail conditioned food

A technology for conditioning food and processing methods, which is applied in the processing field of crayfish and shrimp tail flavor conditioning food, which can solve the problems of high raw material cost, high logistics cost, and loss of elastic taste, etc., to achieve control of microbial growth, good texture and characteristic indicators, and maintain Effects on taste quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing method for crayfish shrimp tail flavor conditioning food, comprising the following steps:

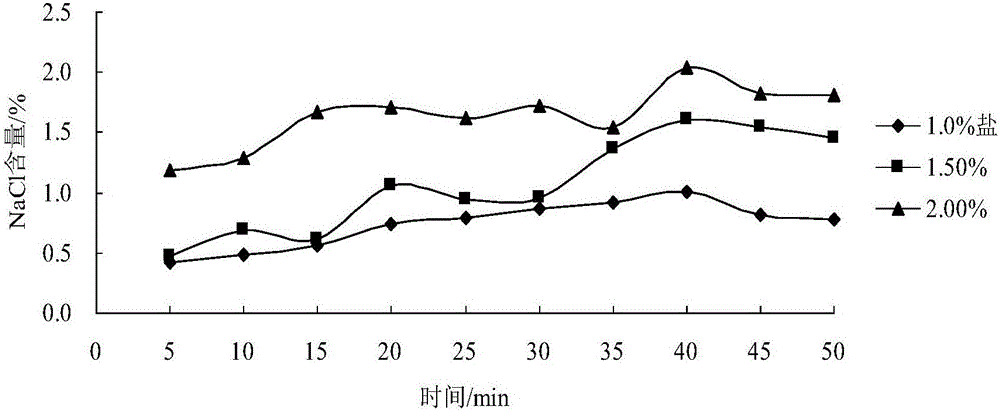

[0029] (1) Vacuum tumbling pickling: get fresh and alive crayfish with shelled shrimp tail, remove the shrimp line, add pickling solution, the salt concentration in the pickling solution is 1.0wt%, compound phosphate (composite phosphate is made of tripolymer Sodium phosphate, sodium pyrophosphate, trisodium phosphate, and sodium hexametaphosphate are compounded at a mass ratio of 2:2:2:1) concentration 1.0wt%, trehalose concentration 2.0wt%, sodium erythorbate concentration 1.0wt%, Adopt vacuum tumbling technology (tumbling vacuum degree 0.02MPa, rotating speed 10r / min) to marinate for 30min;

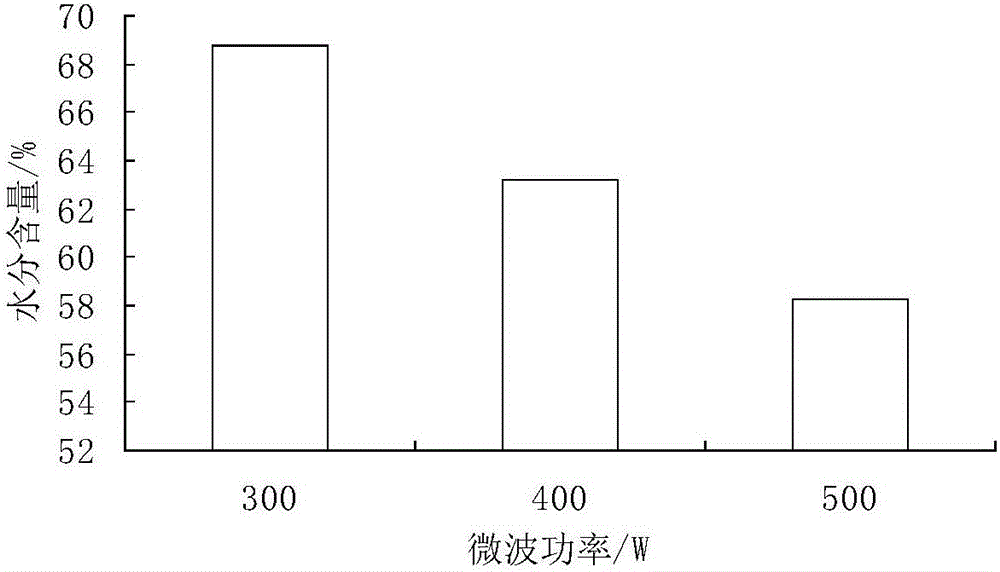

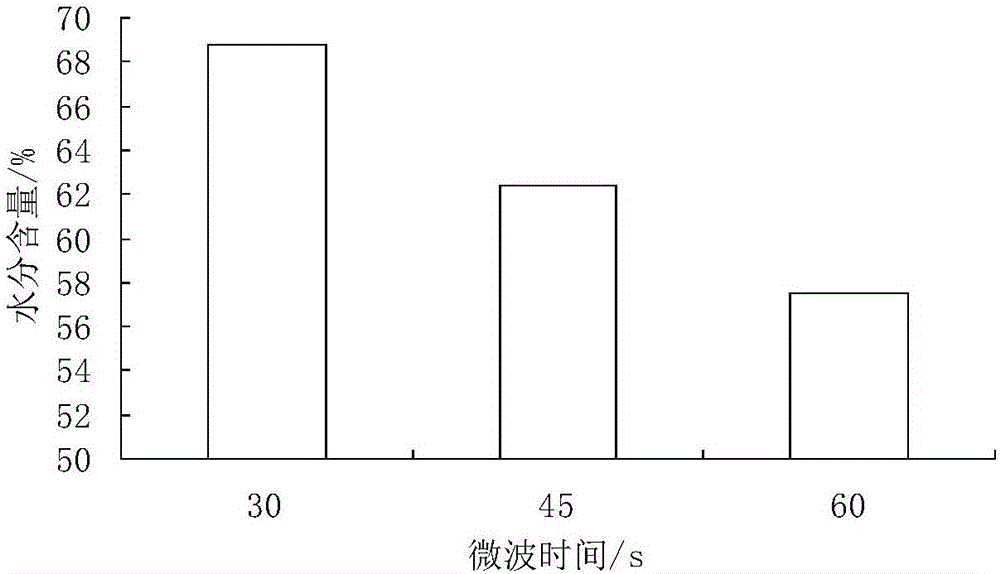

[0030] (2) Microwave: Carry out microwave pretreatment to crayfish shrimp tail, microwave power is 300W, and microwave time is 60s;

[0031] (3) Frying: Deep-fry the crayfish and shrimp tails at high temperature, using soybean oil, at an oil temperature of 140°C, and fry for...

Embodiment 2

[0036] A processing method for crayfish shrimp tail flavor conditioning food, comprising the following steps:

[0037] (1) Vacuum tumbling and pickling: get fresh and alive crayfish with shelled shrimp tail, remove the shrimp thread, add pickling liquid, the salt concentration in the pickling liquid is 1.5wt%, compound phosphate (composite phosphate is made of tripolymer Sodium phosphate, sodium pyrophosphate, trisodium phosphate, and sodium hexametaphosphate are compounded according to the mass ratio of 2:2:2:1) concentration 2.0wt%, trehalose concentration 3.0wt%, sodium erythorbate concentration 1.5wt%, Adopt vacuum tumbling technology (tumbling vacuum degree 0.03MPa, rotating speed 15r / min) to marinate for 40min;

[0038] (2) Microwave: Carry out microwave pretreatment to crayfish shrimp tail, microwave power is 400W, and microwave time is 45s;

[0039] (3) Frying: Deep-fry the crayfish tails at high temperature, using soybean oil, at an oil temperature of 150°C, for 2 mi...

Embodiment 3

[0044] A processing method for crayfish shrimp tail flavor conditioning food, comprising the following steps:

[0045] (1) Vacuum tumbling and pickling: get fresh and alive crayfish with shelled shrimp tail, remove the shrimp line, add pickling liquid, the salt concentration in the pickling liquid is 2wt%, compound phosphate (composite phosphate is made of tripolyphosphoric acid Sodium, sodium pyrophosphate, trisodium phosphate, and sodium hexametaphosphate are compounded according to the mass ratio of 2:2:2:1) concentration 3.0wt%, trehalose concentration 4.0wt%, sodium erythorbate concentration 2wt%, using vacuum Tumbling technology (tumbling vacuum degree 0.04MPa, speed 20r / min) marinated for 45min;

[0046] (2) Microwave: Carry out microwave pretreatment to crayfish shrimp tail, microwave power is 500W, and microwave time is 30s;

[0047] (3) Frying: Deep-fry the crayfish and shrimp tails at high temperature, using soybean oil, at an oil temperature of 160°C, for 1.5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com