Seafood mushroom dish and preparation method thereof

A technology of shiitake mushrooms and seafood, which is applied in the field of food processing, can solve the problems of undiscovered shiitake mushrooms and seafood, and achieve the effect of retaining chewiness, easy digestion, and rich salty and fresh layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

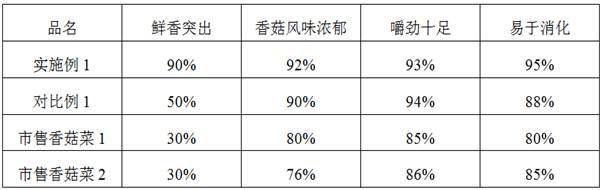

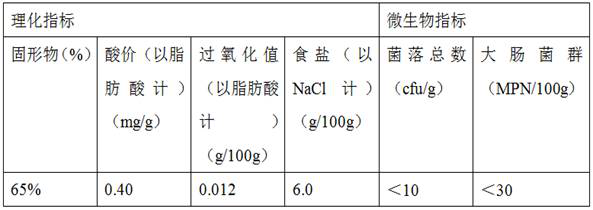

Examples

Embodiment 1

[0026] The raw materials are as follows:

[0027] 45 parts of mushroom stalks, 10 parts of dried scallops, 10 parts of dried shrimp, 3 parts of salt, 2 parts of soy sauce, 0.5 parts of white sugar, 0.3 parts of dried radish, 0.3 parts of seaweed, 0.004 parts of potassium sorbate, appropriate amount of soybean oil.

[0028] Its preparation process is:

[0029] (1) Soak the shiitake stalks in clean water for 6 hours after removing impurities;

[0030] (2) After soaking the shiitake mushroom stalks, wash and remove the sundries;

[0031] (3) The washed mushroom stalks are pressed to remove more than 80% of the water and loosen the tissue;

[0032] (4) The loosened shiitake mushroom stalks are beaten into a φ1-2mm wire rope by an automatic shredded machine at 25rpm / min to obtain shiitake mushroom shreds;

[0033] (5) Use cellulase to enzymatically hydrolyze shredded shiitake mushrooms for 6 hours;

[0034] (6) Put the shredded shiitake mushrooms after enzymolysis into an elect...

Embodiment 2

[0040] The raw materials are as follows:

[0041] 43 parts of mushroom stalks, 8 parts of dried scallops, 12 parts of dried shrimp, 4 parts of salt, 3 parts of soy sauce, 0.4 parts of white sugar, 0.4 parts of dried radish, 0.2 parts of seaweed, 0.003 parts of potassium sorbate, appropriate amount of soybean oil.

[0042] Its preparation process is:

[0043] (1) Soak the shiitake stalks in clean water for 5 hours after removing impurities;

[0044] (2) After soaking the shiitake mushroom stalks, wash and remove the sundries;

[0045] (3) The washed mushroom stalks are pressed to remove 85% of the water and loosen the tissue;

[0046] (4) The loosened shiitake mushroom stalk is beaten into a φ1-2mm wire rope shape by an automatic shredded machine at 20rpm / min to obtain shiitake mushroom shreds;

[0047] (5) Use cellulase to enzymatically hydrolyze shredded shiitake mushrooms for 7 hours;

[0048] (6) Put the shredded shiitake mushrooms after enzymolysis into the electromagn...

Embodiment 3

[0051] The raw materials are as follows:

[0052] 48 parts of mushroom stalks, 12 parts of scallops, 8 parts of dried shrimp, 3 parts of salt, 2 parts of soy sauce, 0.5 parts of white sugar, 0.3 parts of dried radish, 0.2 parts of seaweed, 0.003 parts of potassium sorbate, appropriate amount of soybean oil.

[0053] Its preparation process is:

[0054] (1) Soak the shiitake stalks in clean water for 8 hours after removing impurities;

[0055] (2) After soaking the shiitake mushroom stalks, wash and remove the sundries;

[0056] (3) The washed mushroom stalks are pressed to remove 90% of the water and loosen the tissue;

[0057] (4) The loosened shiitake mushroom stalk is beaten into a φ1-2mm wire rope by an automatic shredded machine at 30rpm / min to obtain shiitake mushroom shreds;

[0058] (5) Use cellulase to enzymatically hydrolyze shredded shiitake mushrooms for 5 hours;

[0059] (6) Put the enzymatically hydrolyzed shredded shiitake mushrooms into an electromagnetic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com