Wire sleeve feeding device

A feeding device and bushing technology, applied in the field of wire threading, can solve problems such as unfavorable wire passing through processing, unstable bushing feeding, and low work efficiency, achieving significant economic benefits, stable output, and reduced labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

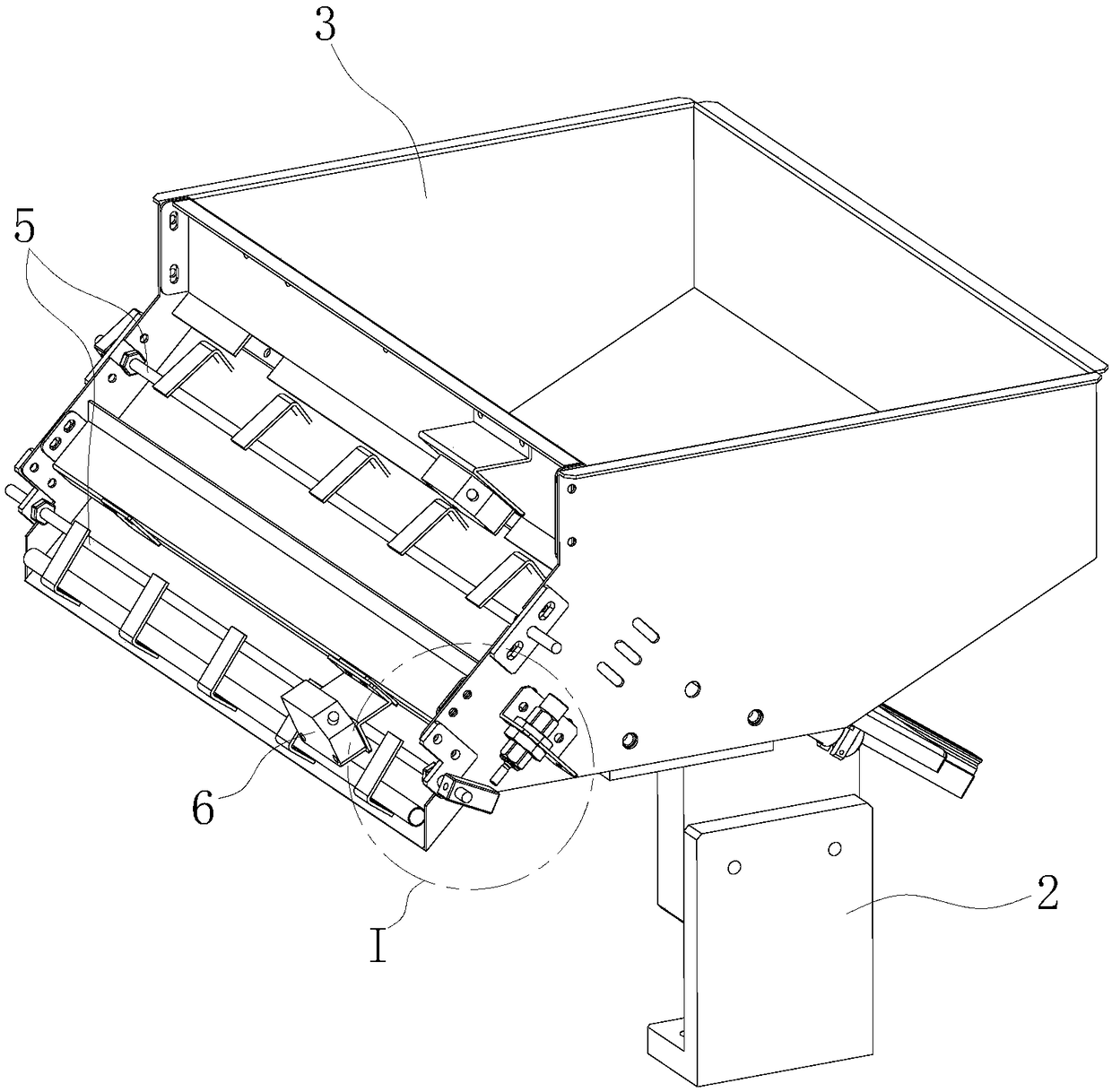

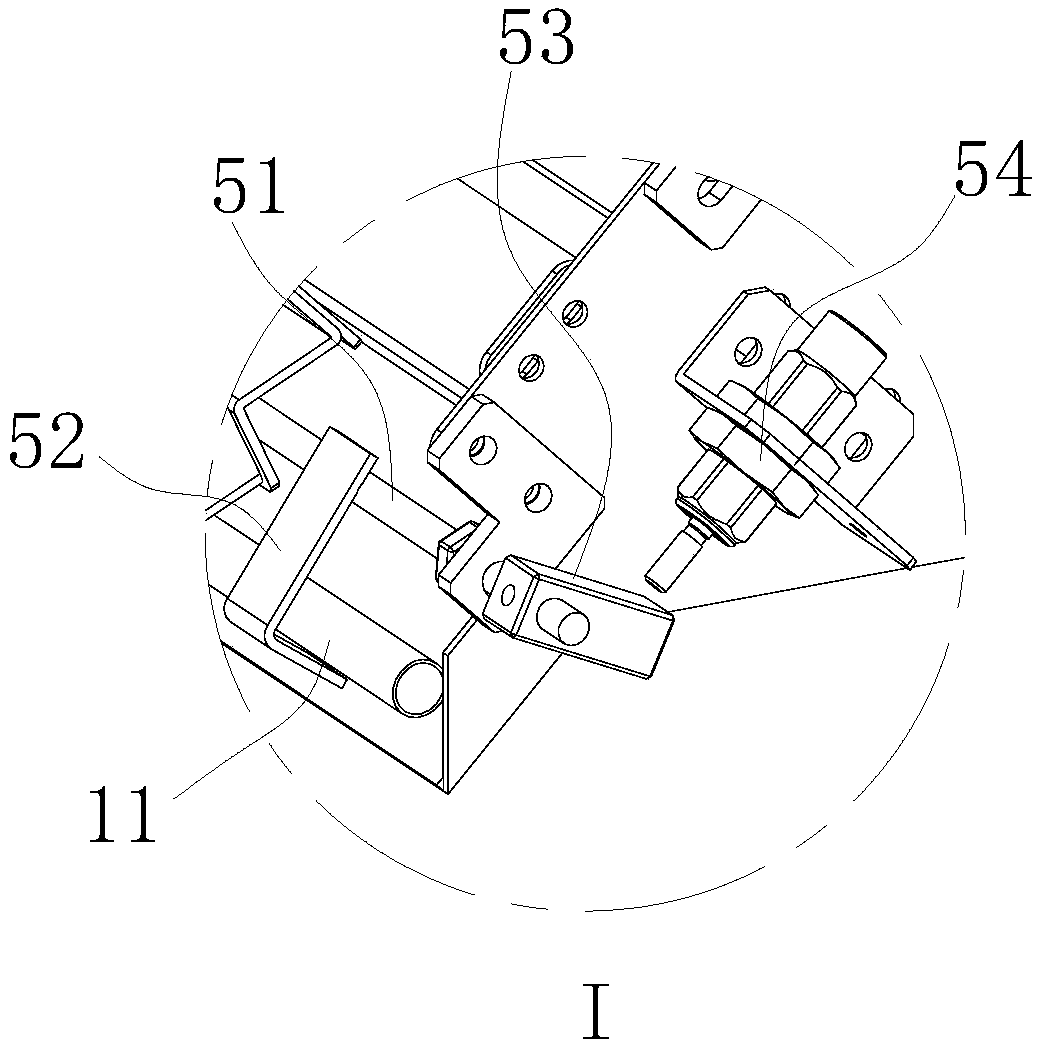

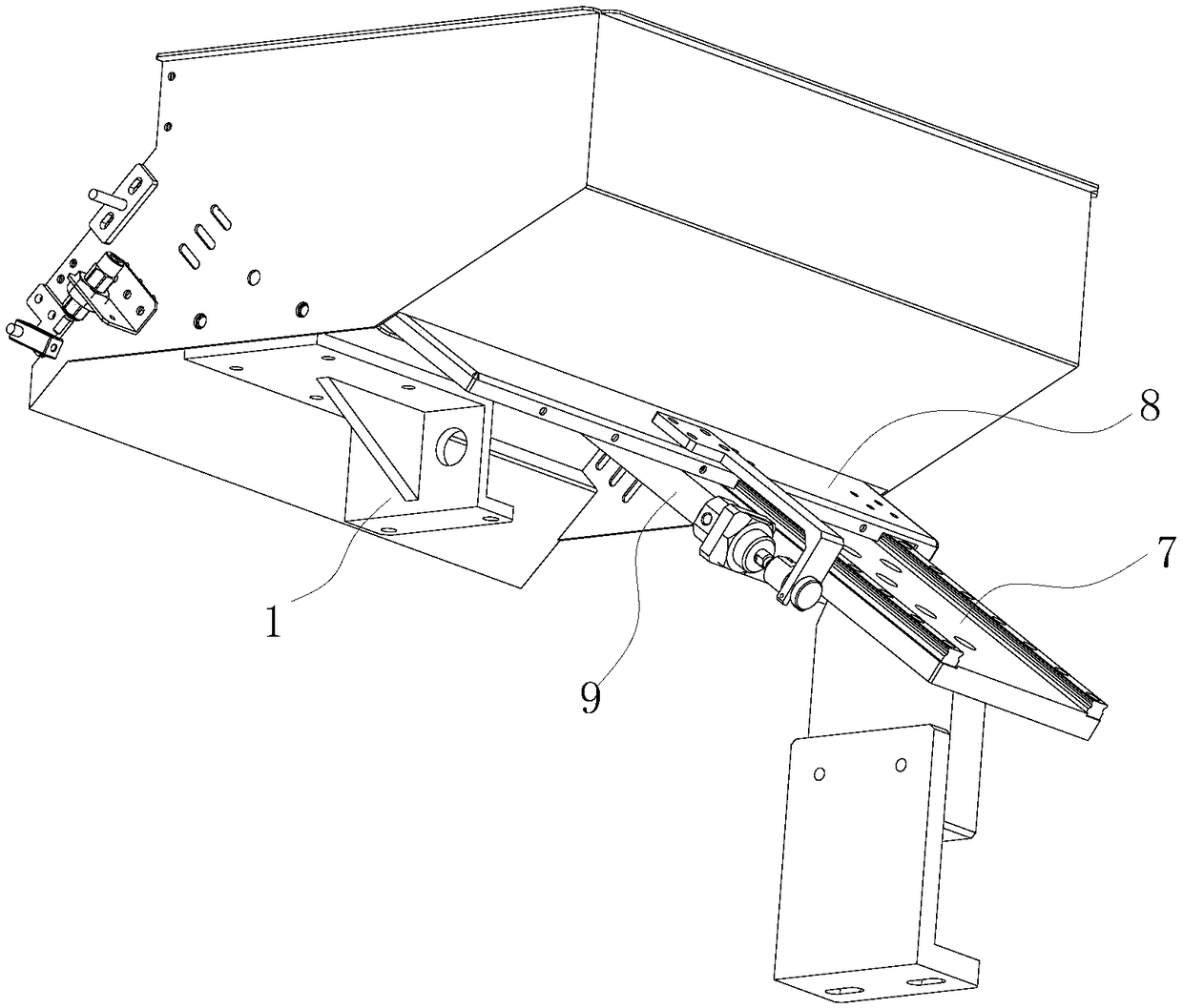

[0021] Such as Figure 1 to Figure 6 As shown, a wire casing feeding device includes a first mounting plate 1, a second mounting plate 2, a conical material box 3 fixed on the first mounting plate 1 and having an open bottom, connected to the conical material There is a material guide plate 4 on the box 3 and a material outlet 3a between the opening, a lever mechanism 5 close to the material guide plate 4 and flipping the release sleeve 11, a photoelectric sensor 6 close to the lever mechanism 5, and a tapered The rear side of the material box 3 and the slide rail 7 fixed on the second mounting plate 2, the pusher plate 8 installed on the slide rail 7 and located in the discharge port 3a, connected with the pusher plate 8 and fixed on the slide rail 7 hydraulic rod 9 at the bottom. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com