Laser feeding device

A laser and feeding technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low work efficiency of the staff, and achieve good connection effect, high work smoothness, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below through specific examples.

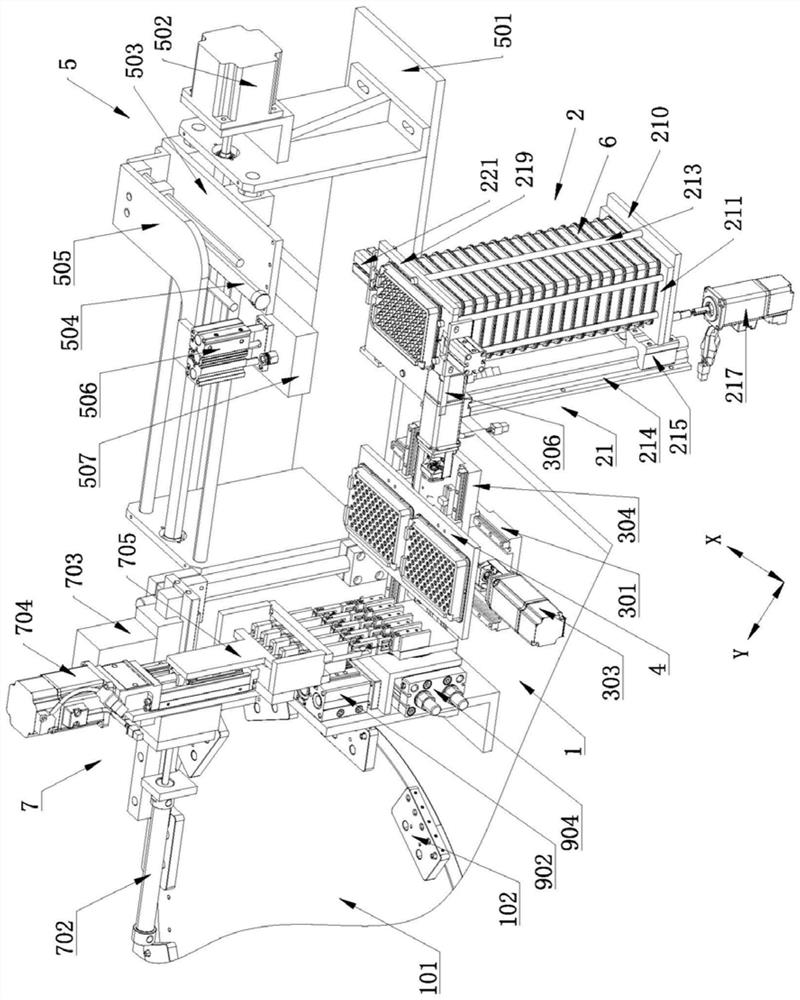

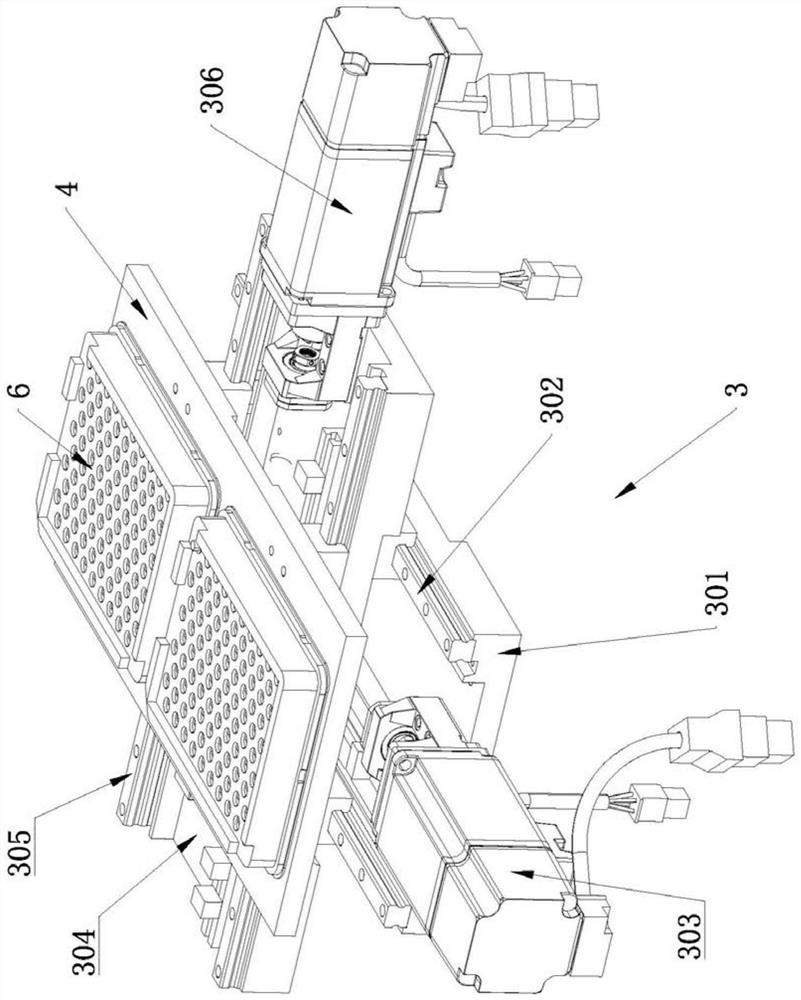

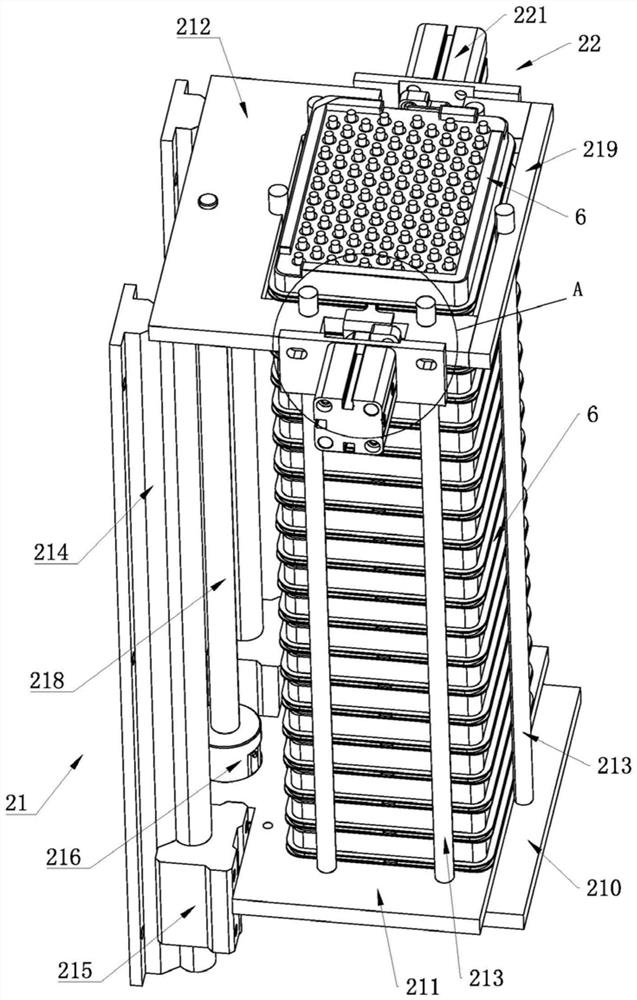

[0044] Such as figure 1 As shown, a laser supply device, a laser supply device, includes a frame 1, on which a turntable driven by a drive device (such as a combined drive structure of a motor and a reducer, not shown in the figure) is mounted on the frame 1 101, the frame 1 is provided with a vertical box storage rack 2, the frame 1 located downstream of the box storage rack 2 is provided with an adjustment mechanism 3, and the adjustment mechanism 3 is provided with a box placement platform 4. A box body transfer mechanism 5 for transferring the box body 6 between the box body placement table 4 and the box body storage rack 2 is provided on the frame 1 located on one side of the box body storage rack 2; the turntable 101 The upper annular array has a plurality of copper pipe material holders 102 (a plurality of holes for inserting copper pipes and vertically arranged holes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com