Electroplating product support frame structure

A support frame and product technology, applied in the electrolysis process, electrolysis components, household components, etc., can solve the problems of bumping and wearing of electroplated parts, affecting product quality and aesthetics, affecting production efficiency, etc., to improve work efficiency, ensure quality and aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

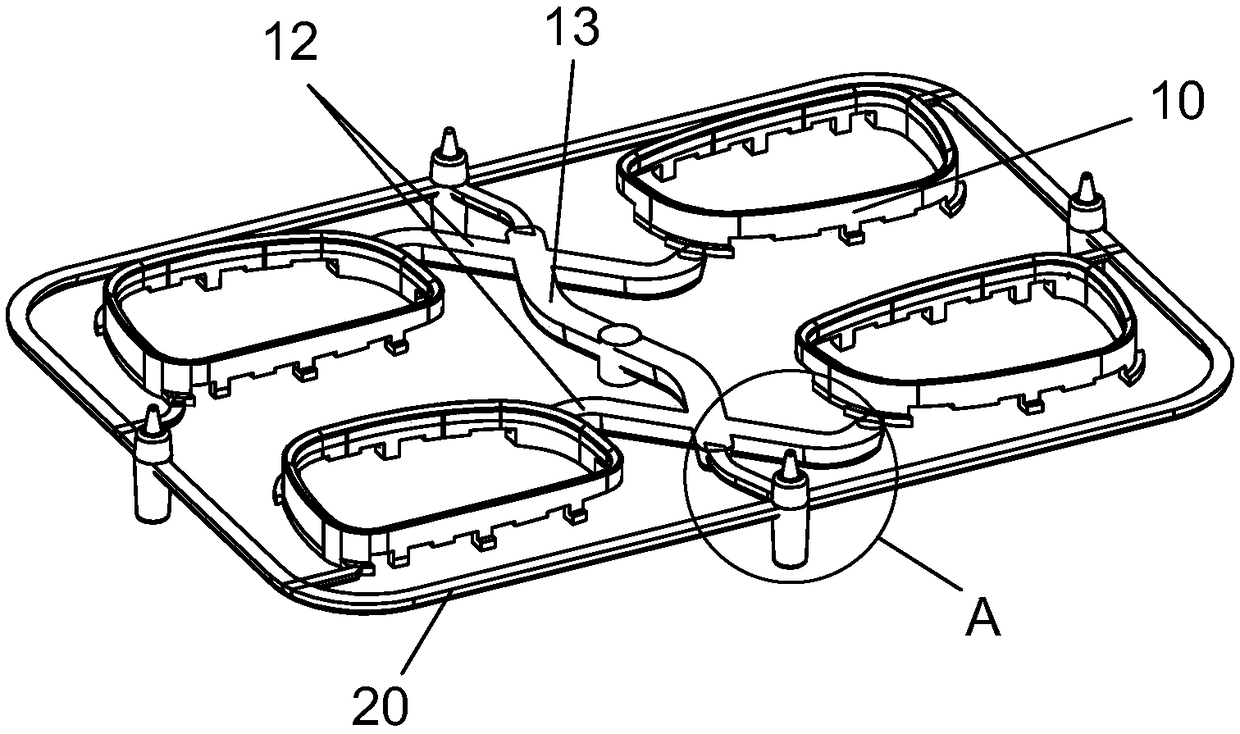

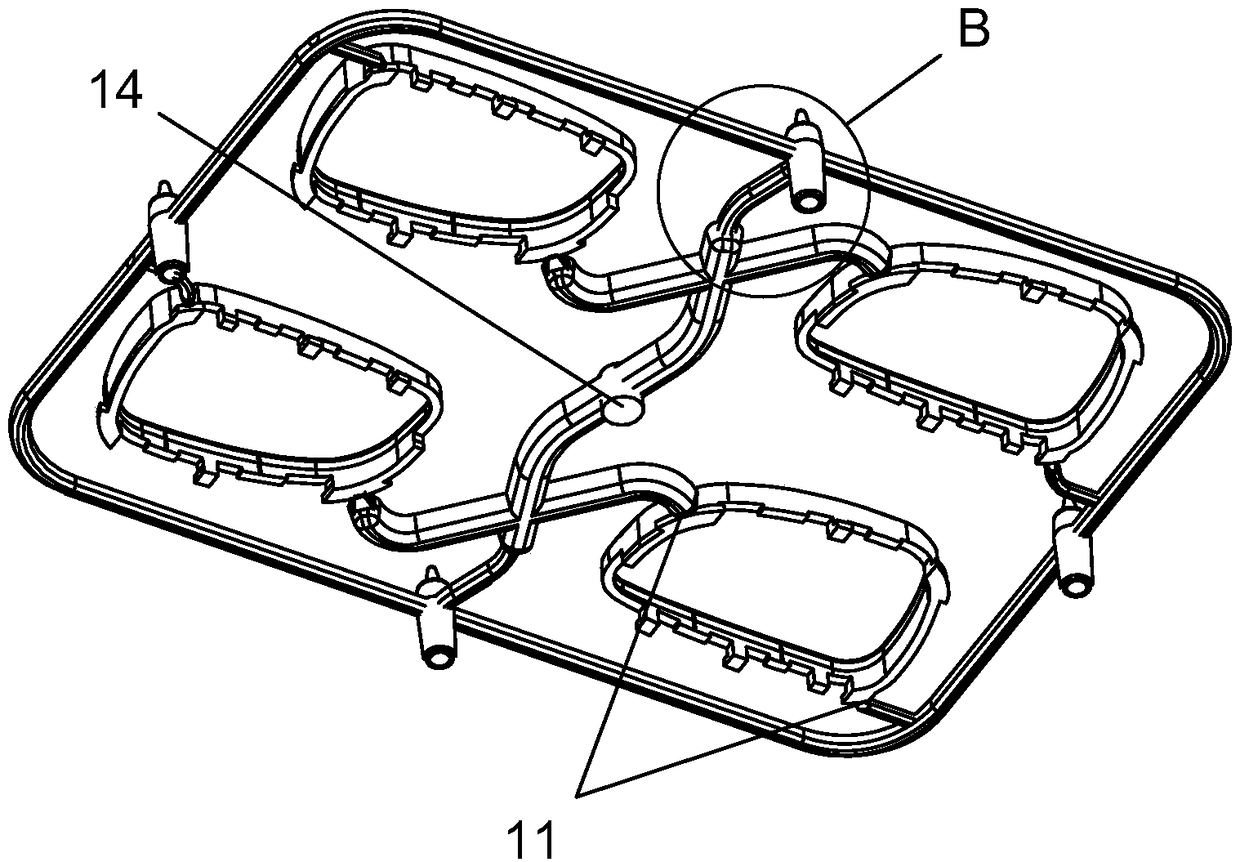

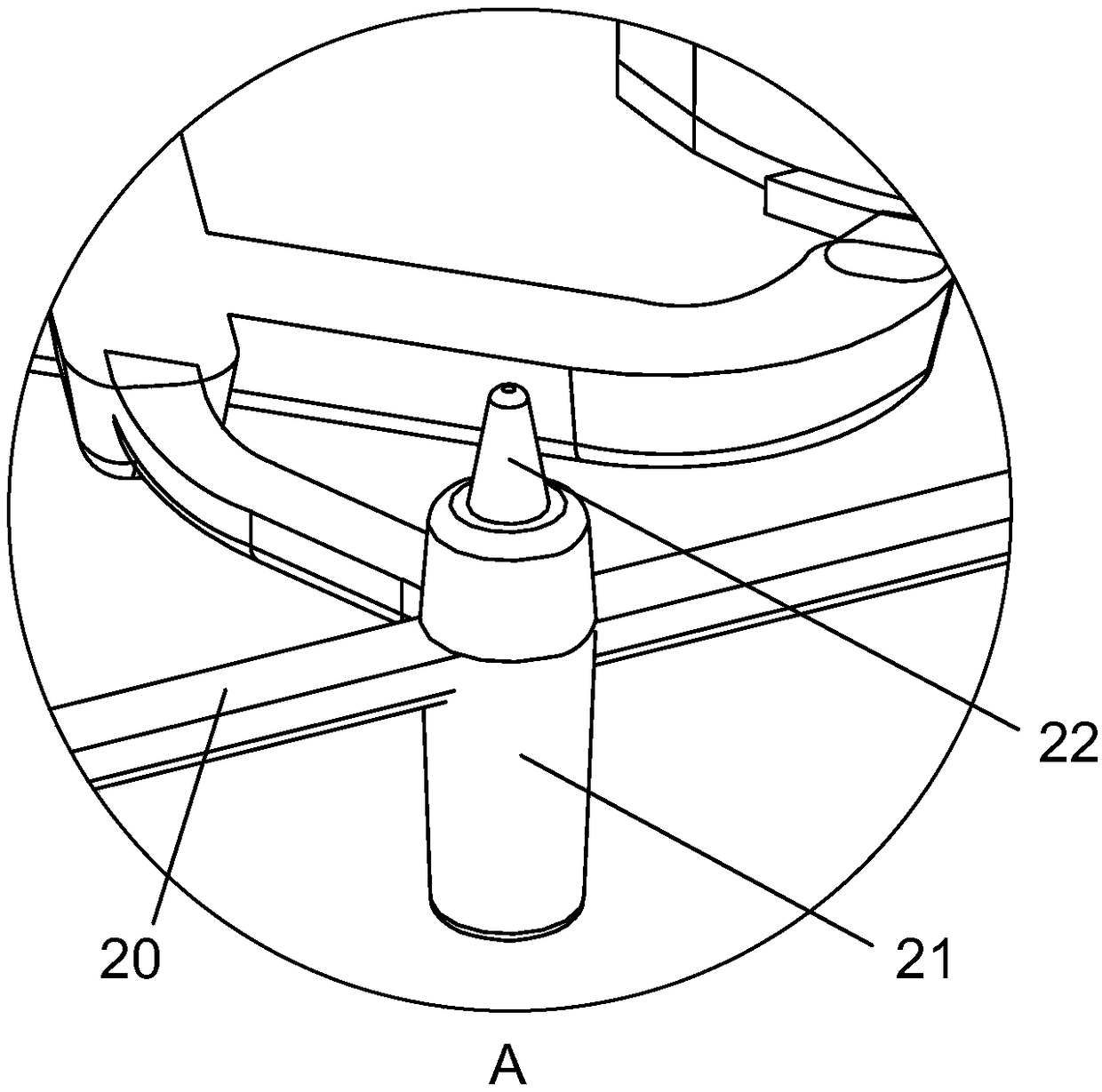

[0021] refer to Figure 1 to Figure 5 ,Such as Figure 1 to Figure 5 The shown electroplating product support frame structure includes at least one electroplating product 10, the outer edge of the electroplating product 10 is connected with a gate 11, and the gate 11 is connected with a support frame 20 arranged around the electroplating product 10, the The support frame 20 is provided with a support column 21, one end of the support column 21 is provided with a positioning protrusion 22, and the other end is provided with a positioning pit 23 that cooperates with the positioning protrusion 22 when the support columns 21 are stacked. The height is higher than the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com