Automobile front sliding column mistake-proof split charging table

A front spool and sub-packing table technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor consistency of assembly parts, affecting production efficiency, and prone to errors in sub-packaging, to ensure consistency, Improve production efficiency and solve the effect of bumps and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

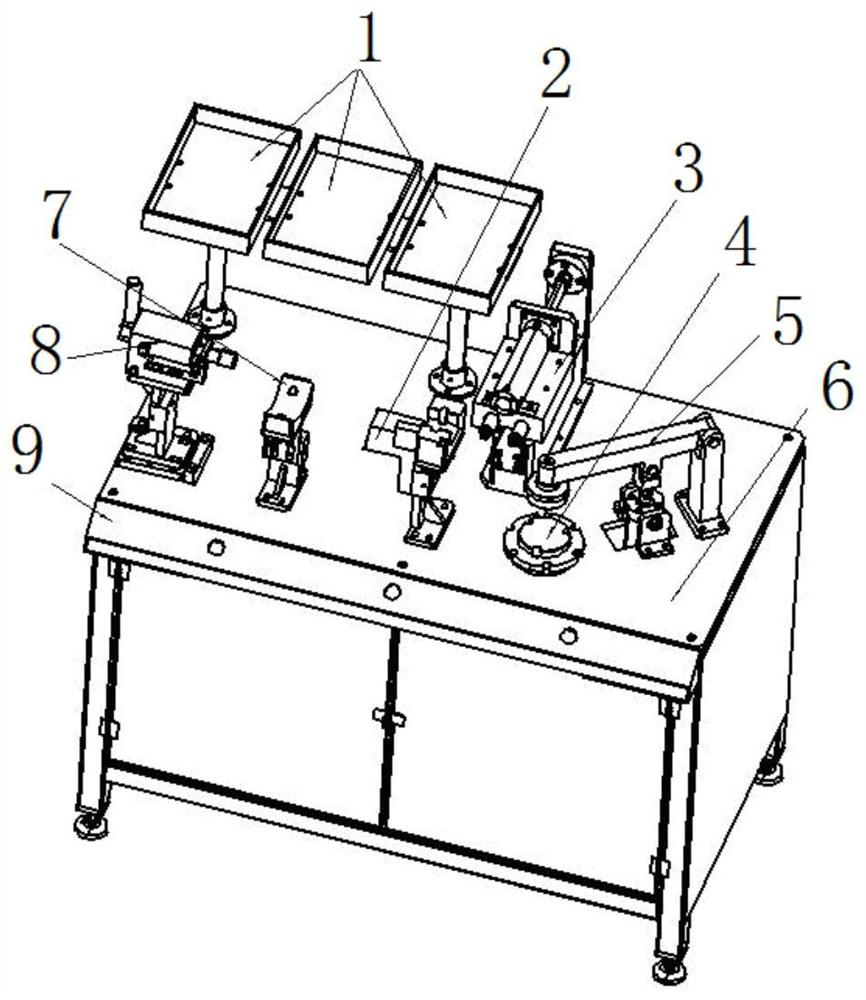

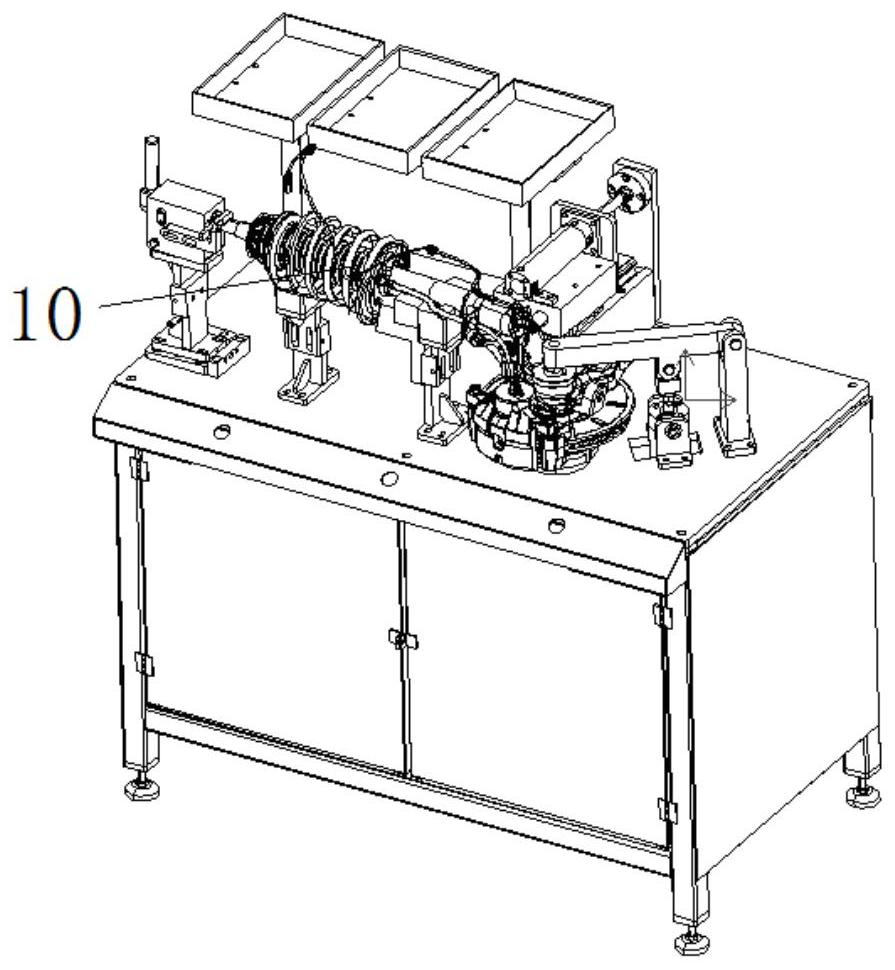

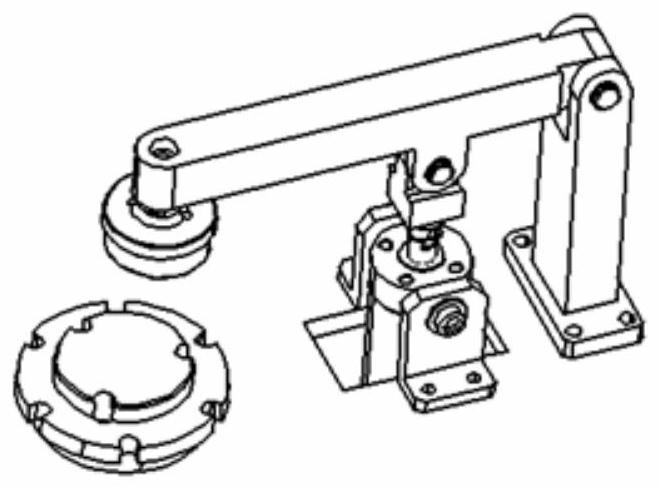

[0025] like Figure 1 to Figure 6 As shown, the automobile front strut error-proof subassembly platform includes a workbench 6 and a brake disc positioning mechanism located on the workbench, a strut support positioning mechanism, and a connecting bolt for pressing the brake disc and the front strut. The fastening bolt compression structure 3 and the strut compression structure 8 for compressing the end of the front strut.

[0026] The strut support positioning mechanism includes a strut support block for supporting the front strut. The strut support block is provided with a strut positioning groove, and one side of the strut support block corresponds to the stabilizer bar mounting bracket 101 on the strut. An anti-mistake limiting block 201 is provided to prevent the left and right front slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com