High-efficiency compound radiator

A heat sink, high-efficiency technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problem of poor thermal radiation and convection effects of radiators, increase ineffective loss and waste of heat energy, and cannot meet the ambient temperature Requirements and other issues, to achieve the effect of reducing low convection efficiency, improving heat utilization rate, and accelerating convection cycle efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

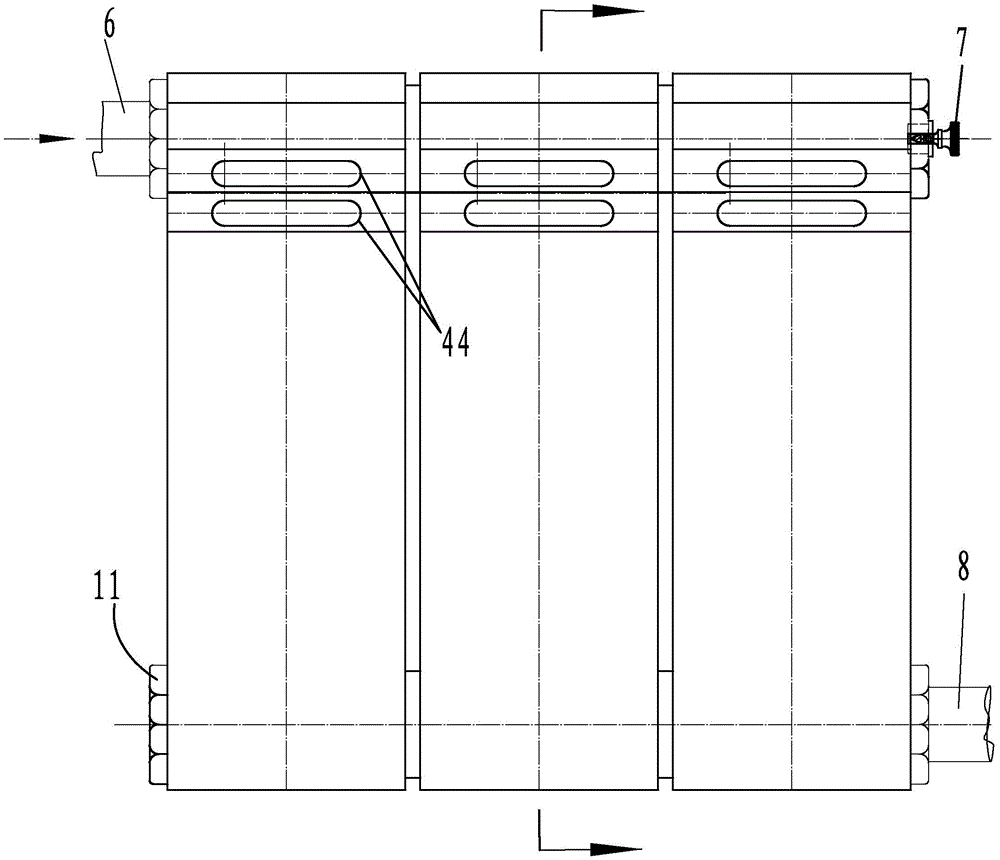

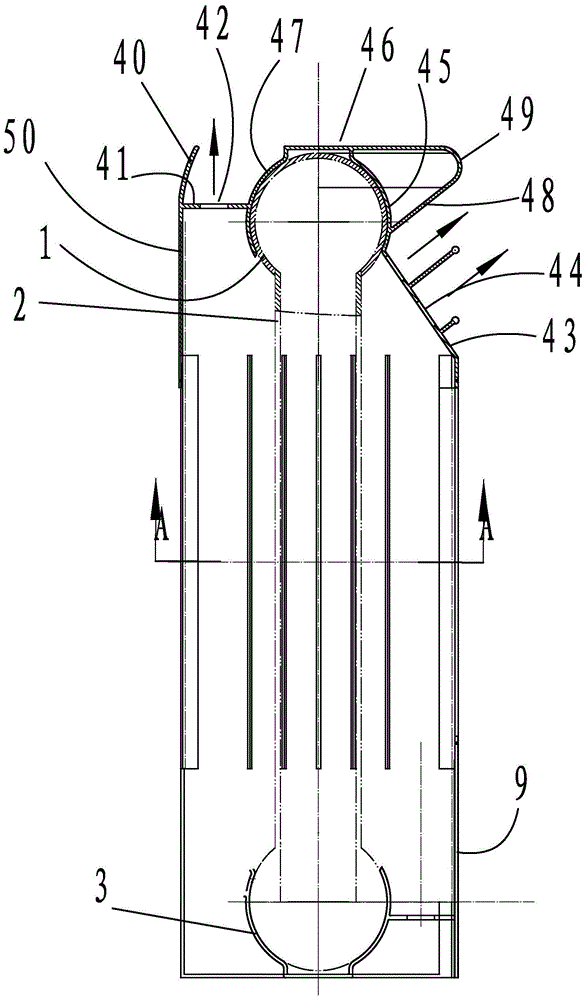

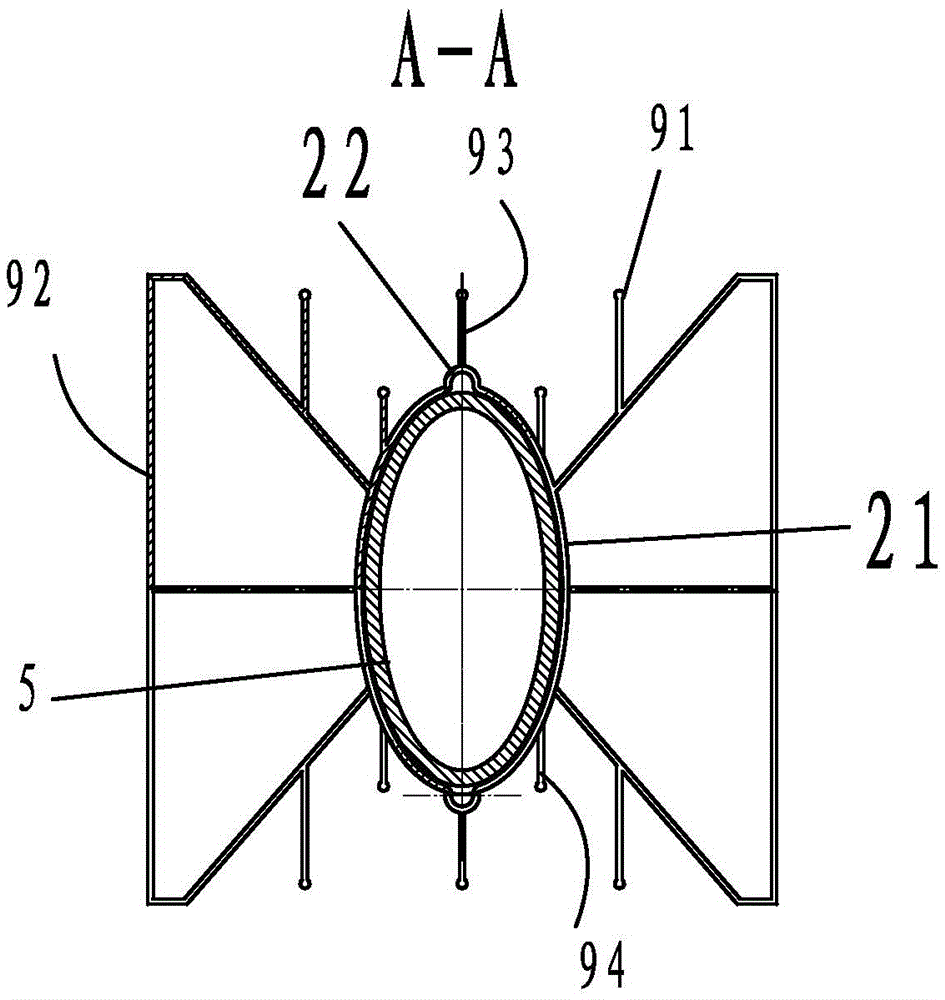

[0022] Such as Figure 1 to Figure 4 As shown, a high-efficiency composite radiator includes an upper header 1, a lower header 3, and the upper header and the lower header are connected by a radiating core tube 5, and a main body radiating tube 2 is sleeved outside the radiating core tube 5. The header 1 is provided with an upper cover 4, and a lower cover 9 with an open lower end is provided on the outside of the main body radiating pipe 2. The lower end of the upper cover 4 is connected with the upper end of the lower cover 9 to form a sealed connection at the connection part. The cover 4 and the lower cover 9 form a hot gas convection circulation channel with an air inlet at the bottom and an air outlet at the upper part. The heat source inlet 6 at one end of the upper header is connected to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com