Injection mould with multi-row oil cylinders linked to drive hot runner

A hot runner injection molding and linkage drive technology, applied in the field of injection mold mechanism design, can solve the problem of inability to use inclined guide posts, and achieve the effects of reliable driving force, reduced manufacturing difficulty, and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

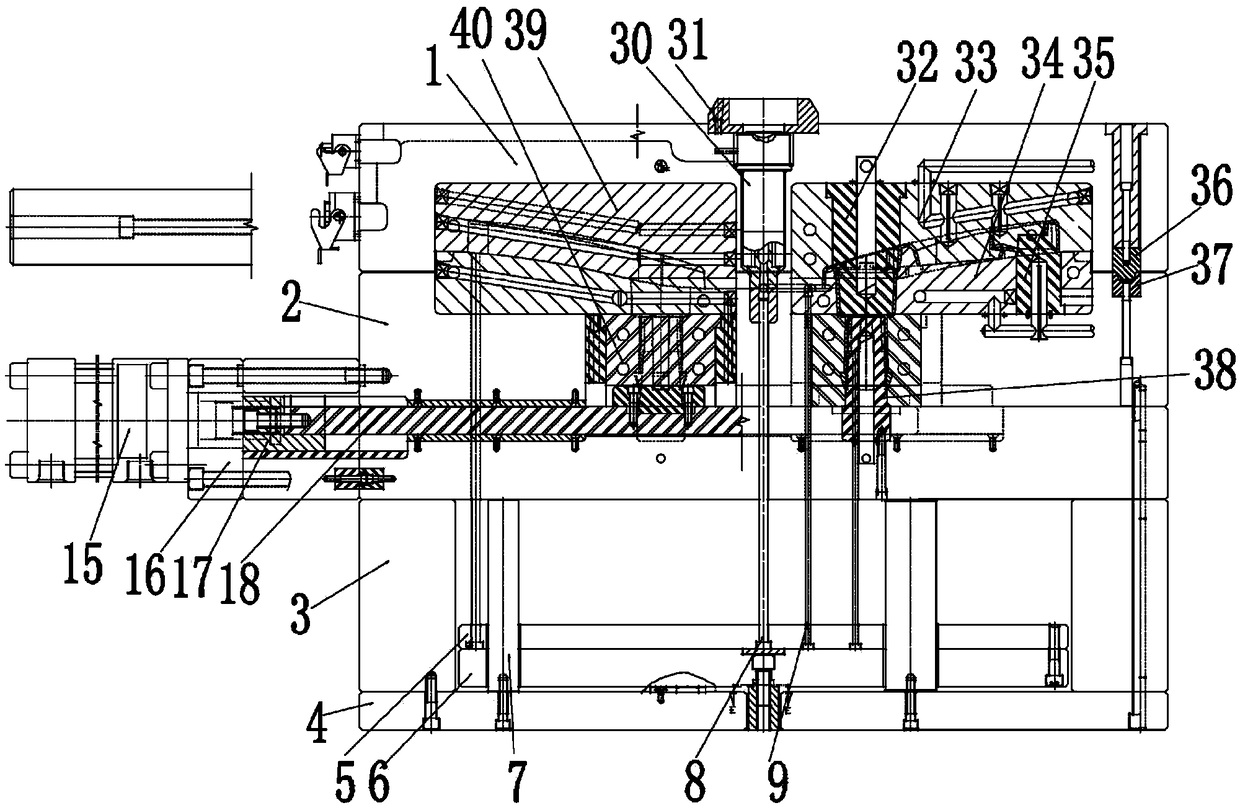

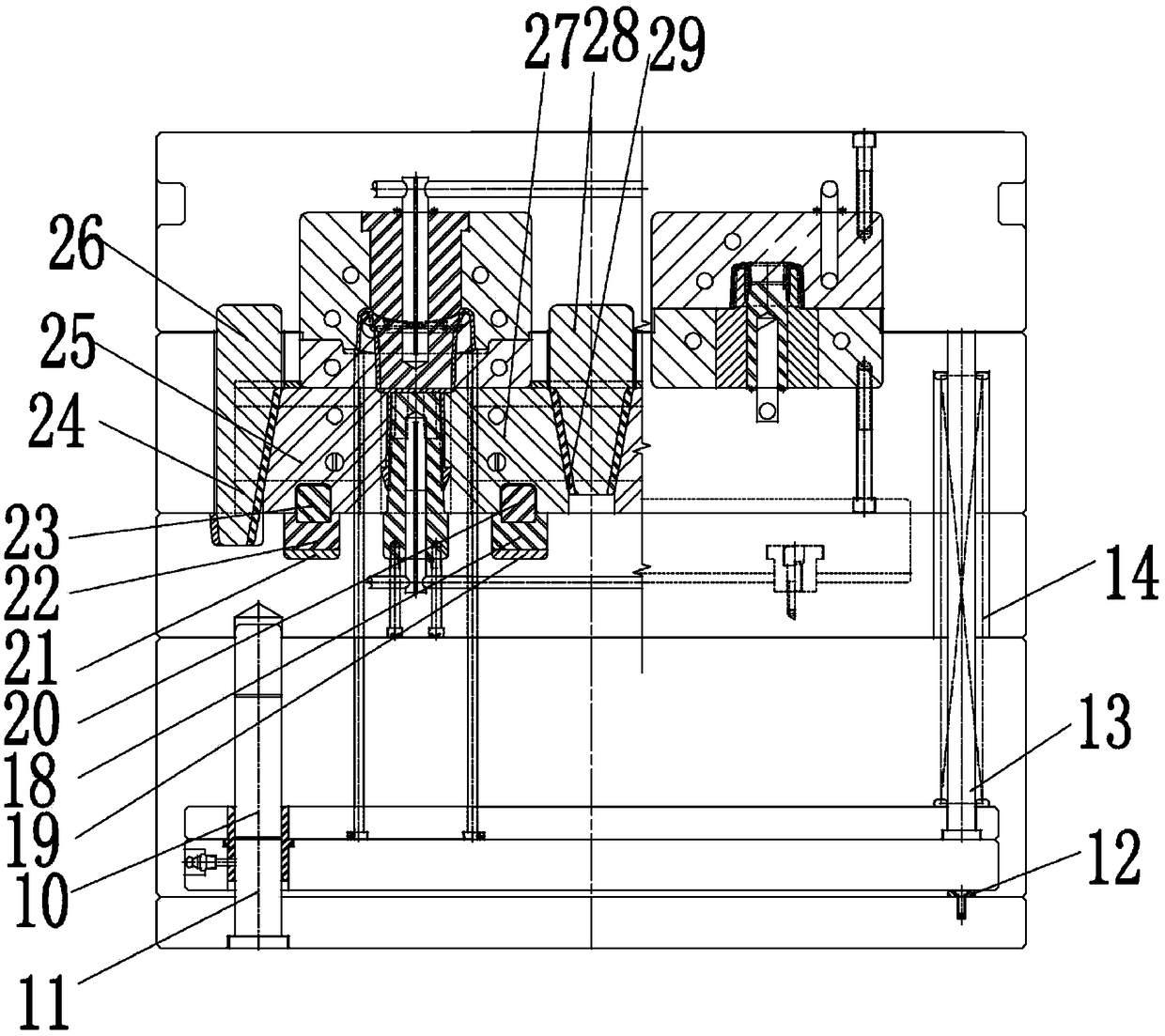

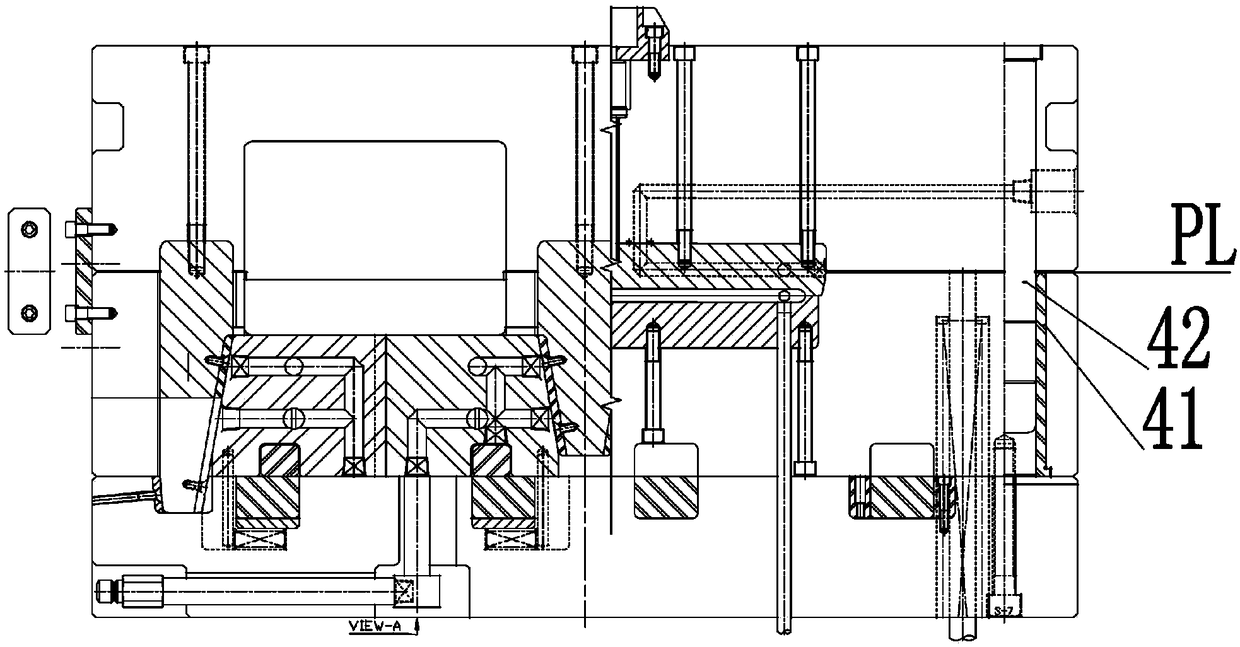

[0019] Figure 1-5 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a multi-row oil cylinder linkage drives a hot runner injection mold, including a fixed template 1, a movable template 2, a mold foot 3, a lower bottom plate 4, a thimble cover plate 5, an thimble push plate 6, a support column 7, and a pull rod 8. Thimble pin 9, thimble plate guide post 10, thimble plate guide sleeve 11, garbage nail 12, reset lever 13, reset lever spring 14, drive cylinder 15, cylinder bracket 16, cylinder slider 17, right drawer 18, right drawer Strip wear plate 19, right locking block 20, left draw bar wear plate 21, left draw bar 22, left lock block 23, left slider bead 24, left slider 25, left slider lock block 26, Right slider 27, right slider locking block 28, right slider bead 29, hot runner nozzle 30, positioning ring 31, B cavity circular insert 32, B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com