Thermoplastic plastic extrusion molding equipment

A thermoplastic extrusion molding technology, applied in the field of thermoplastic extrusion molding equipment, can solve the problems of easy damage to the structure of polymer materials, the inability to guarantee polymer physics, and affect the quality of plastics, so as to ensure stable transmission, Avoid errors and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

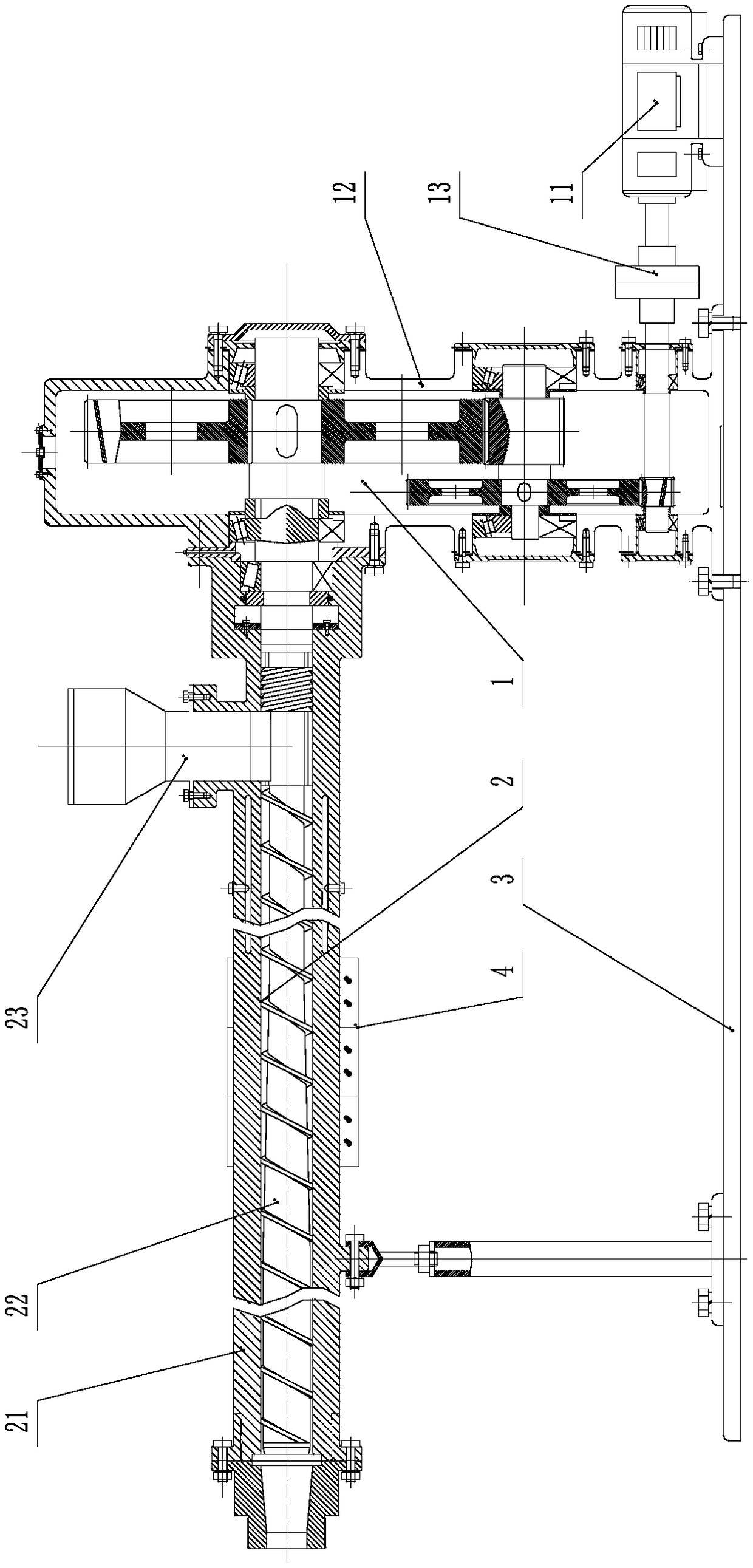

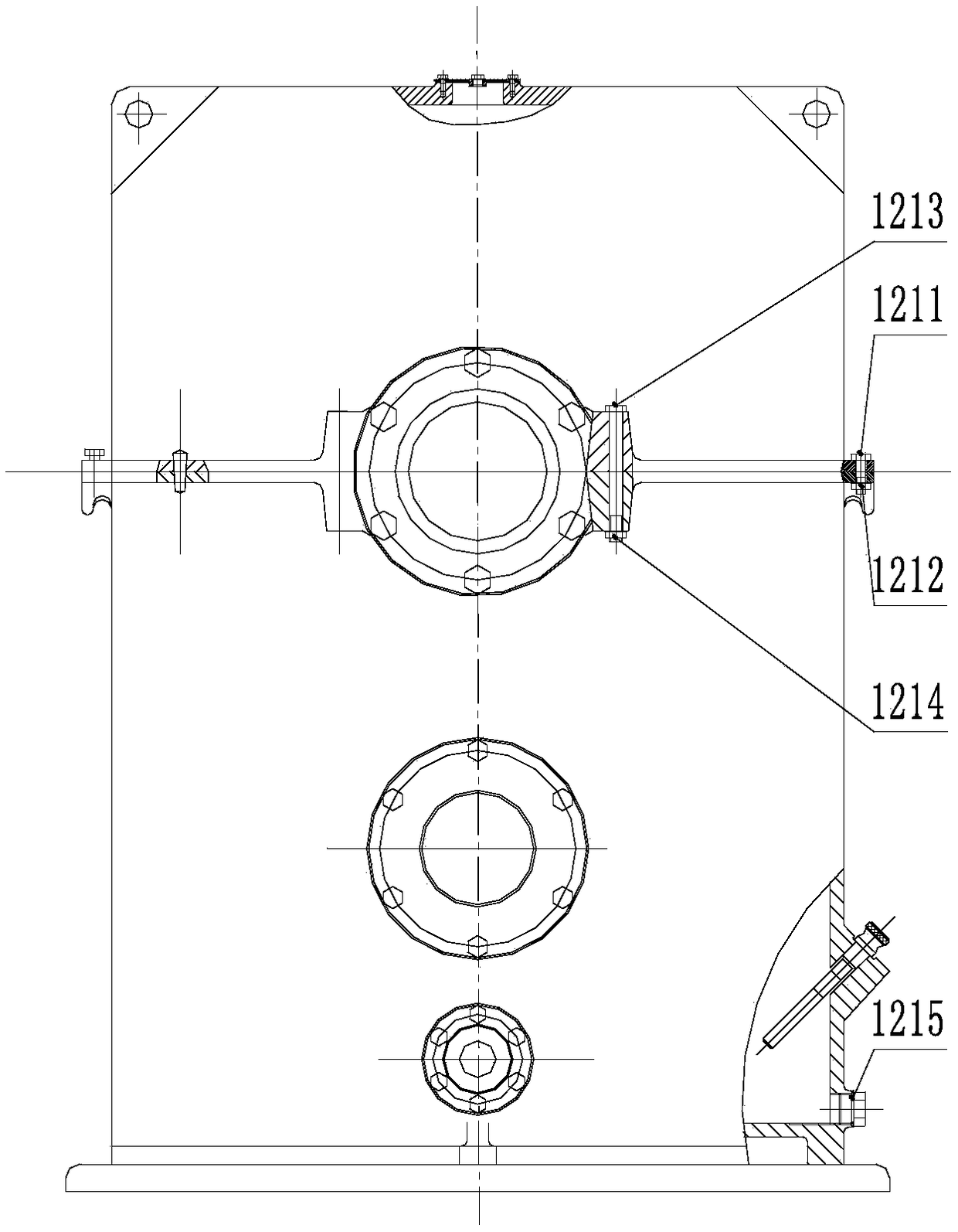

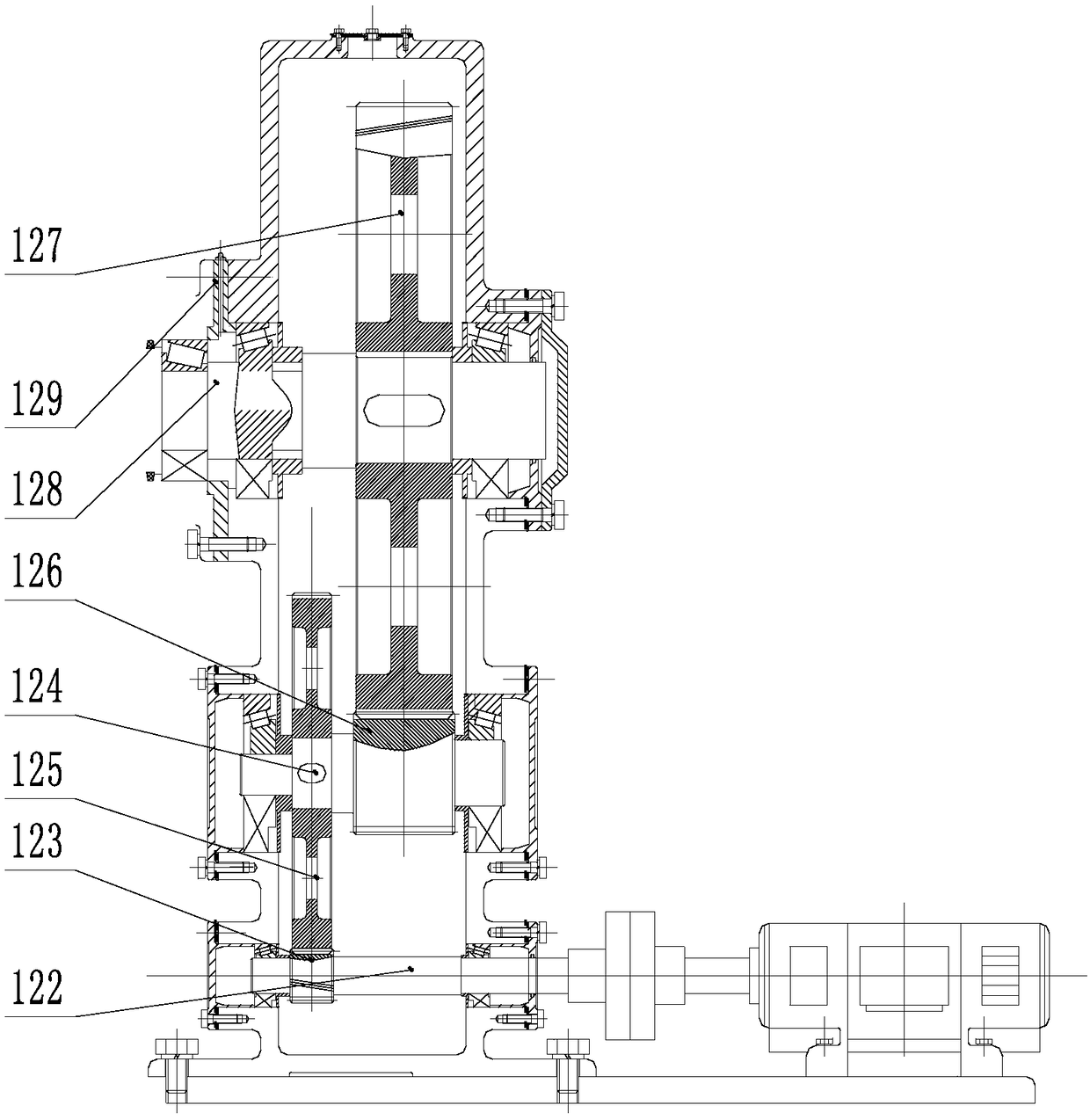

[0035] Embodiment 1 A thermoplastic extrusion molding device according to the present invention includes a workbench 3 for support, a transmission mechanism 1 for providing a rotational driving force to the extrusion molding mechanism, and a transmission mechanism 1 for extruding thermoplastics The extrusion molding mechanism 2, the temperature control mechanism 4 for controlling the temperature inside the extrusion molding mechanism, and the controller for controlling the entire extrusion process, the transmission mechanism 1 and the extrusion molding mechanism 2 are fixed on the workbench 3, wherein the transmission mechanism 1 is arranged upstream of the extrusion molding mechanism 2, and the power output end of the transmission mechanism 1 is fixedly connected to the power input end of the extrusion molding mechanism 2; the control end of the transmission mechanism 1, the The control end of the extrusion molding mechanism 2 is electrically connected with the control end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com