High-transmittance screen protecting film

A screen protective film and light transmittance technology, applied in the screen field, can solve the problems of incomplete reflection of light sources and insensitivity of fingerprint recognition, etc., and achieve the effects of reducing the speed of optical fingerprint recognition, reducing light interference, and small optical path difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

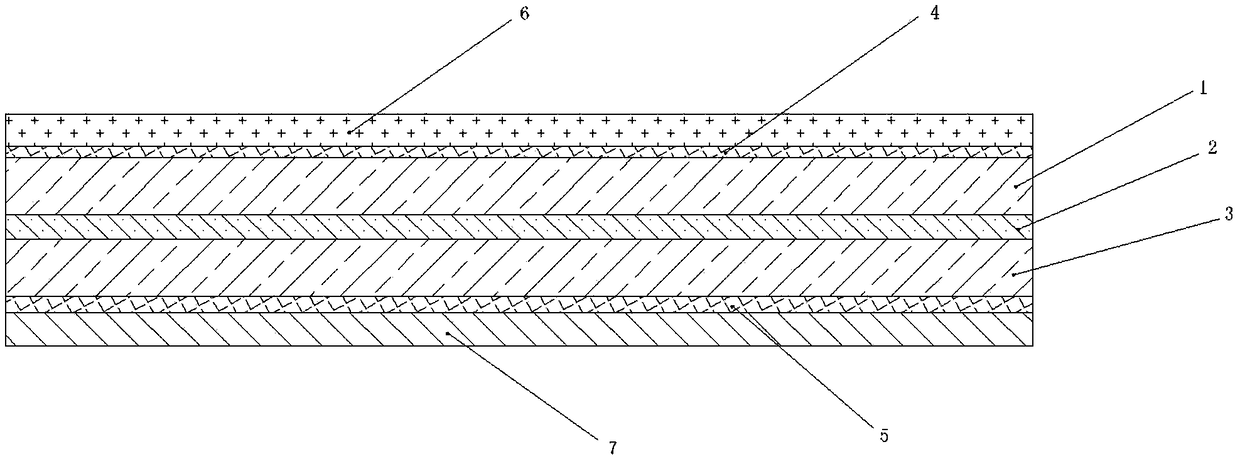

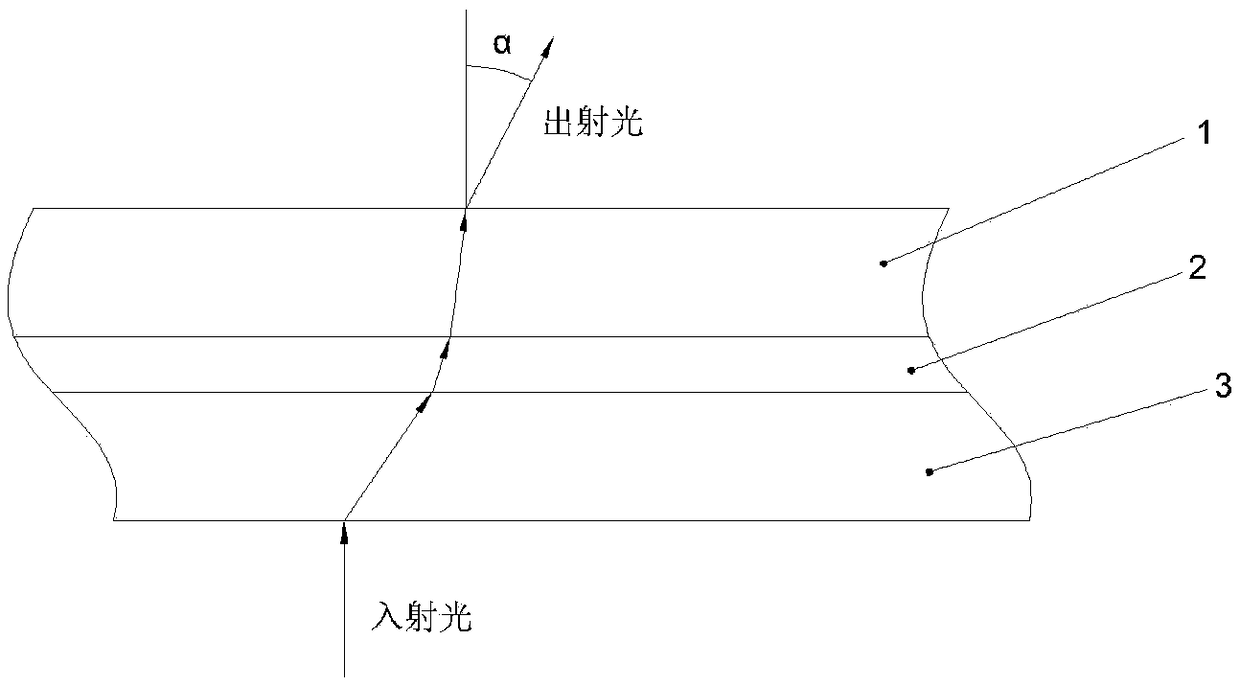

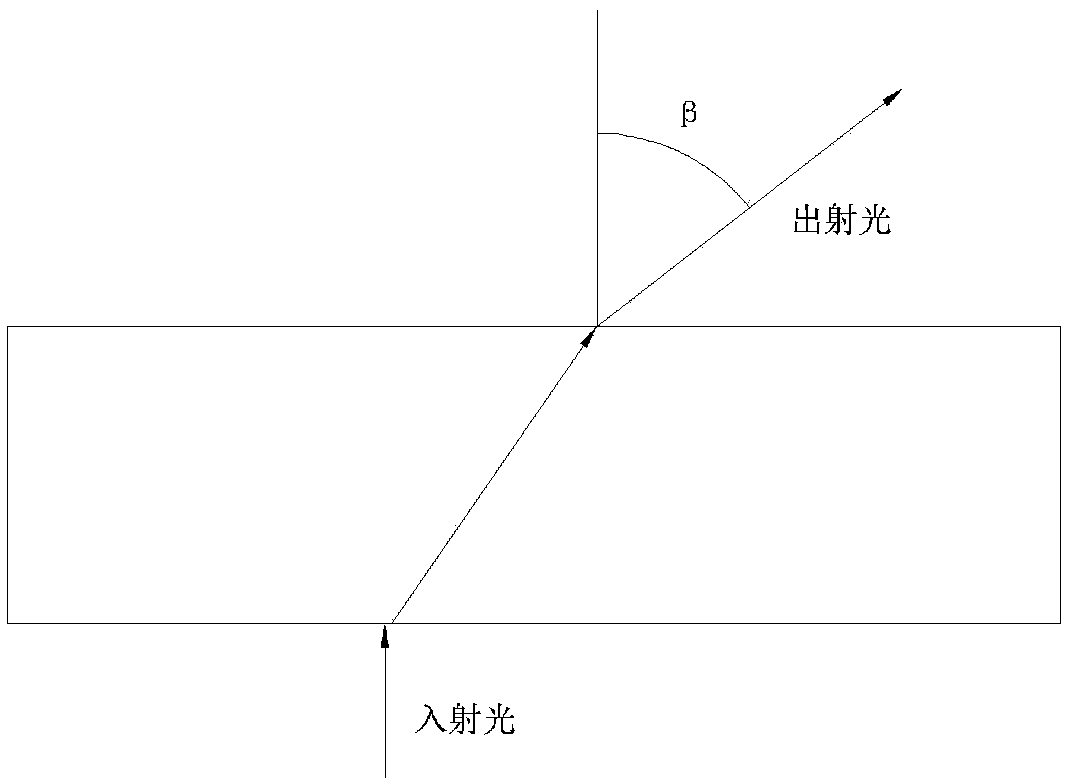

[0028] like Figure 1 to Figure 2 A high light transmittance screen protective film is shown, which is suitable for fingerprint operation equipment under the optical screen. It has a multi-layer structure, and it is characterized in that the screen protective film has an upper PC film layer 1 and a lower PC film layer 3; The upper PC film layer 1 and the lower PC film layer 3 are bonded with an OCA optical adhesive layer 2; the thickness h of the upper PC film layer 1, the OCA optical adhesive layer 2 and the lower PC film layer 3 after being combined is less than 185 μm (micron), the luminous flux φ is not less than 75lm (lumen); the upper surface of the upper PC film layer 1 is coated with a wear-resistant hardened layer 4, and the lower surface of the lower PC film layer 3 is coated with a highly air-permeable glass adhesive layer 5 .

[0029] It should be noted that, in the present embodiment, when the thickness h of the upper PC film layer 1, the OCA optical adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminous flux | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com