Battery health calibration method for power battery

A power battery and calibration method technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as inaccurate calibration of power battery health, and achieve the effect of safe and efficient battery health calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

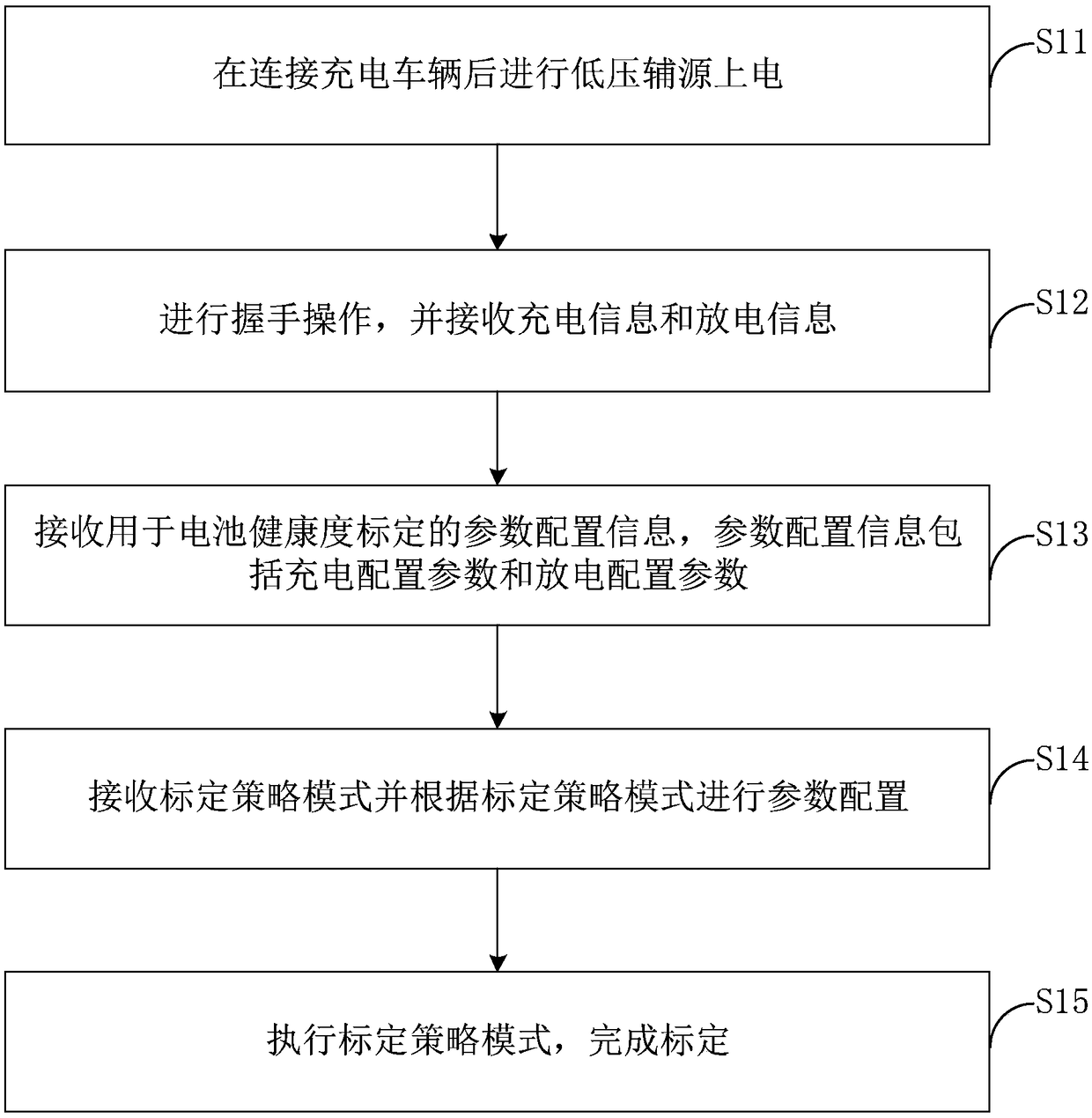

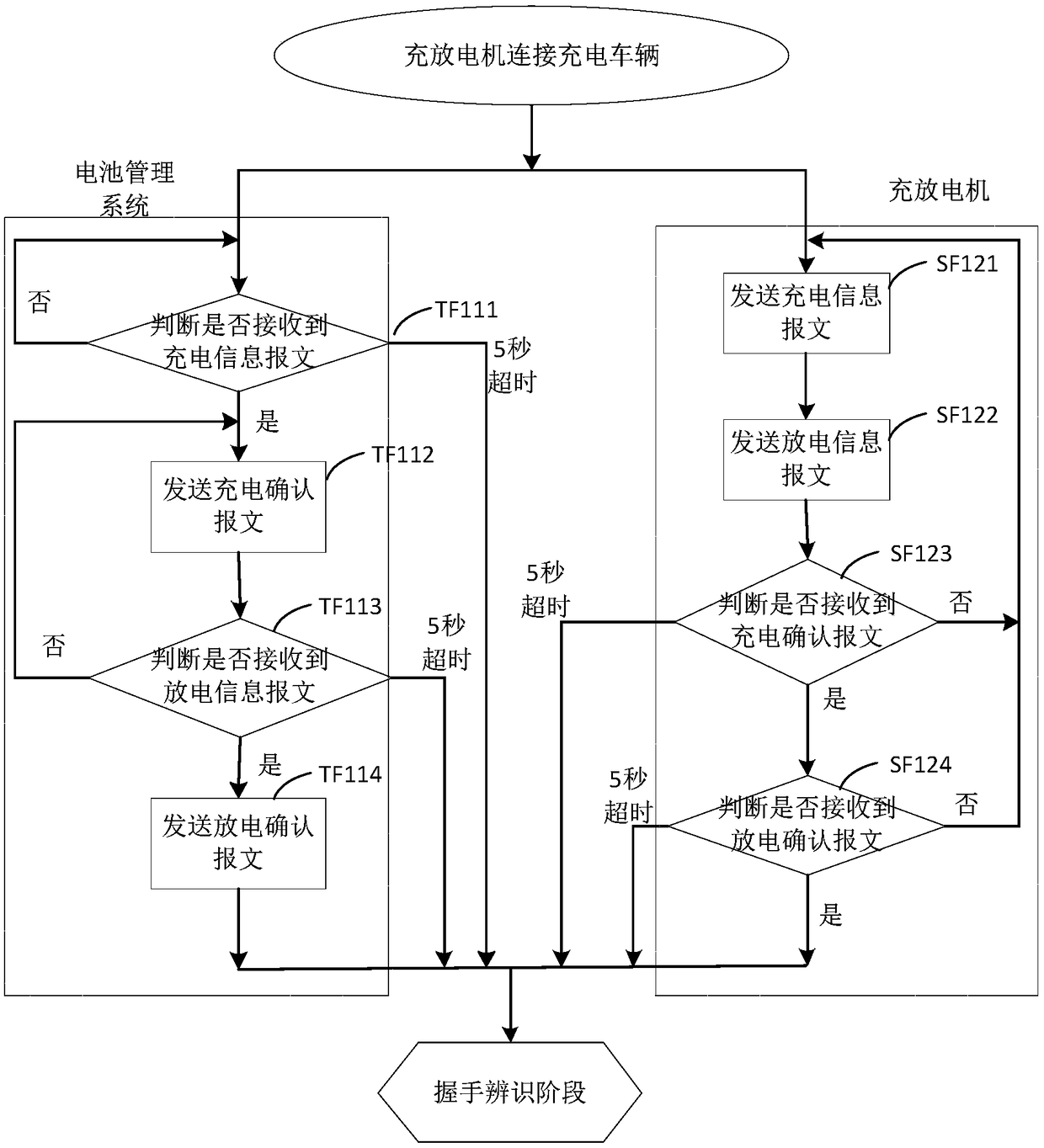

Method used

Image

Examples

no. 1 approach

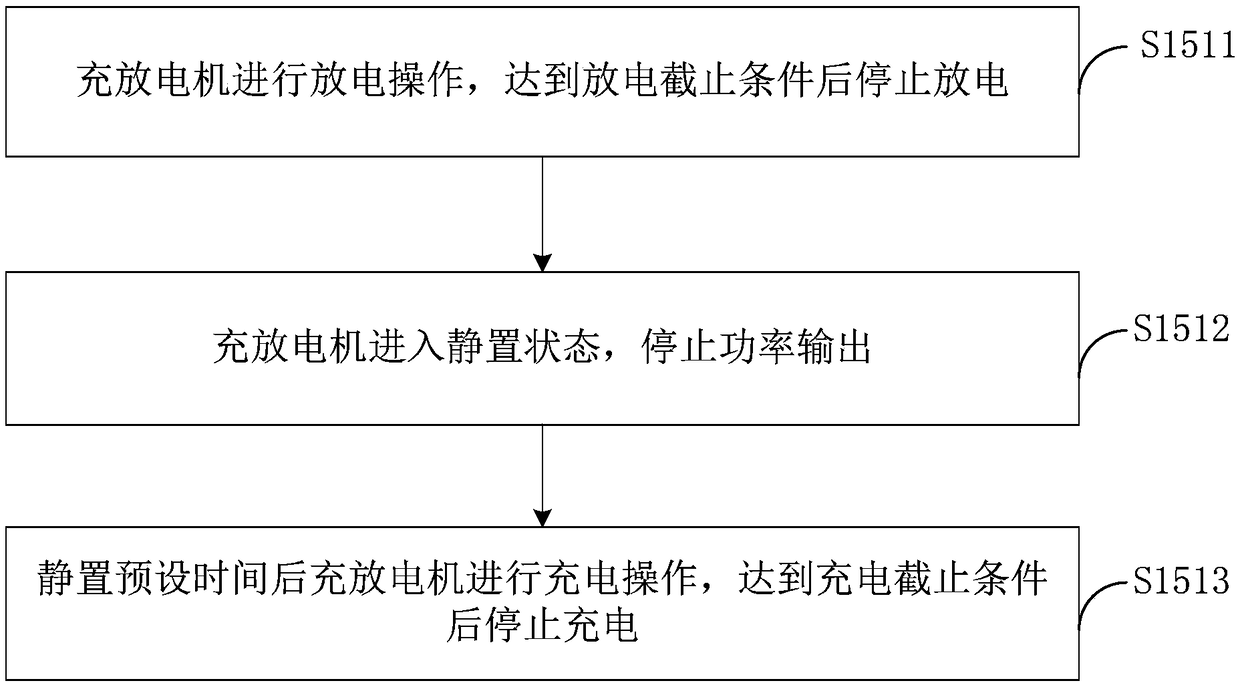

[0084] First embodiment: the calibration strategy mode is discharge-rest-charge mode.

[0085] refer to image 3 , executing the calibration strategy mode in step S15 includes:

[0086] S1511. The charging and discharging motor performs a discharging operation, and stops discharging after reaching a discharge cut-off condition. Firstly, the charge-discharge machine performs discharge operation on the power battery, and monitors in real time whether the discharge cut-off condition information obtained from the battery management system BMS interaction is reached, and stops discharging when the discharge cut-off condition is reached.

[0087] S1512. The charging and discharging motor enters a static state, and stops power output. After the discharge is stopped, the charging and discharging motor and the battery management system enter a static state. In the static stage, the charging and discharging machine does not output power, the auxiliary source of the charging and disch...

no. 2 approach

[0089] The second embodiment: the calibration strategy mode is the charging-resting-discharging mode.

[0090] refer to Figure 4 , executing the calibration strategy mode in step S15 includes:

[0091] S1521. The charging and discharging machine performs a charging operation, and stops charging when the charging cut-off condition is reached. First, the charging and discharging machine performs charging operation on the power battery, and monitors in real time whether the charging cut-off condition information obtained from the battery management system BMS interaction is reached, and stops charging when the charging cut-off condition is reached.

[0092] S1522. The charging and discharging motor enters a static state, and stops power output. After stopping charging, the charging and discharging motor and the battery management system enter a static state. In the static stage, the charging and discharging machine does not output power, the auxiliary source of the charging a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com