Electrical Junction Box with Improved Shell Structure

An electrical junction box and housing structure technology, applied in the field of junction boxes, can solve problems such as difficulty in achieving high-efficiency waterproof performance, and achieve the effect of high-efficiency waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

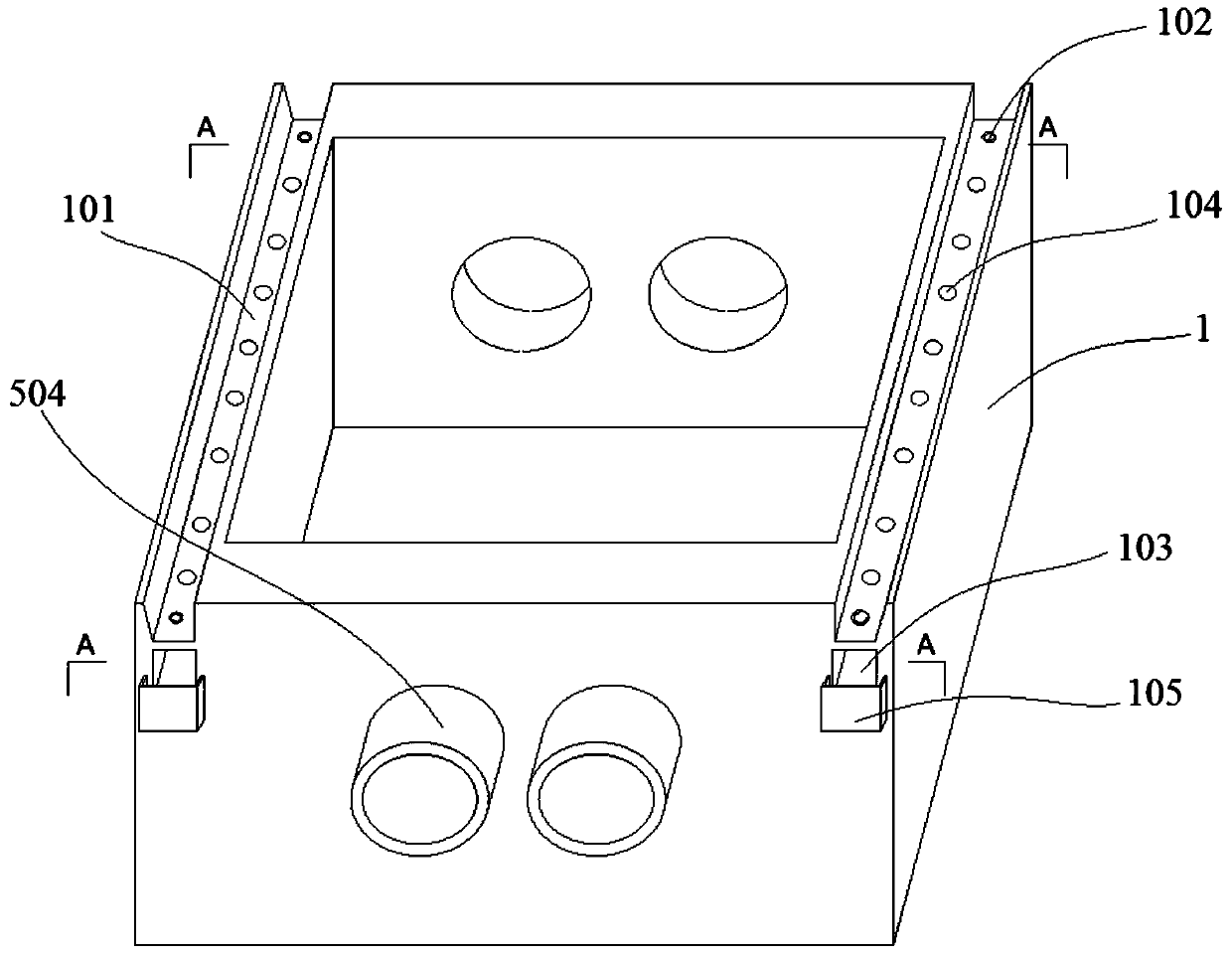

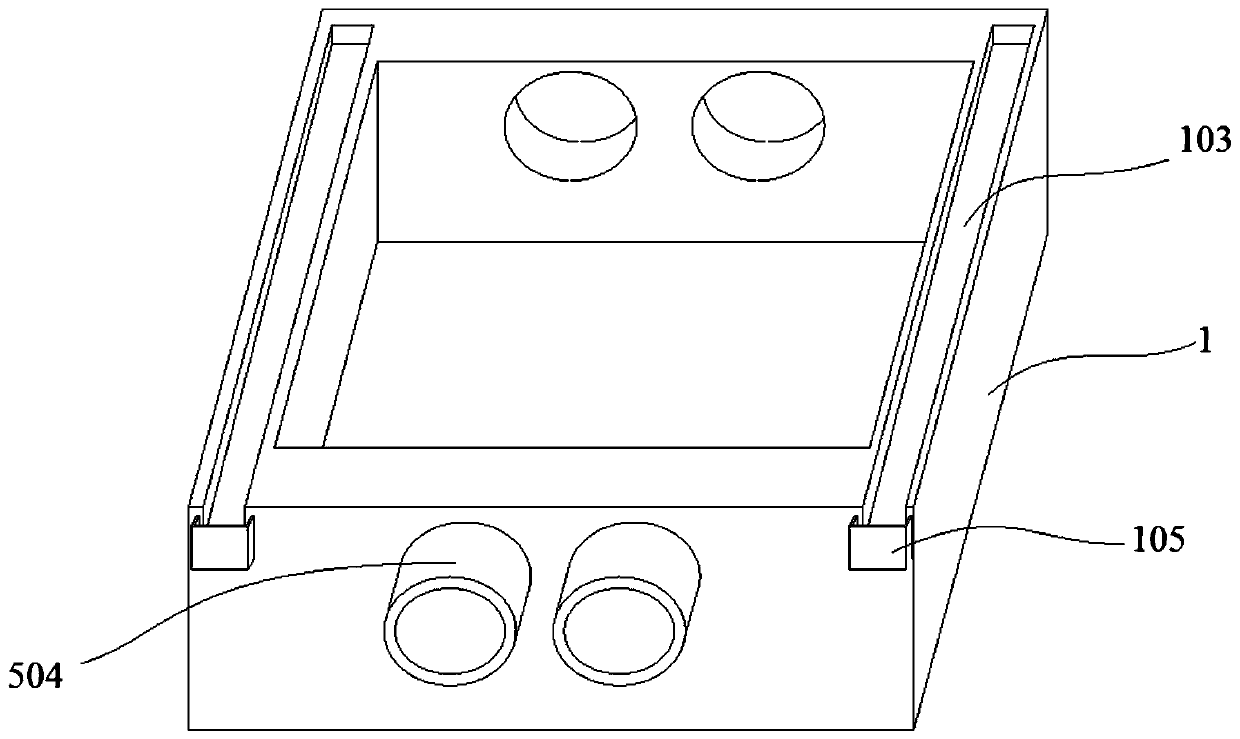

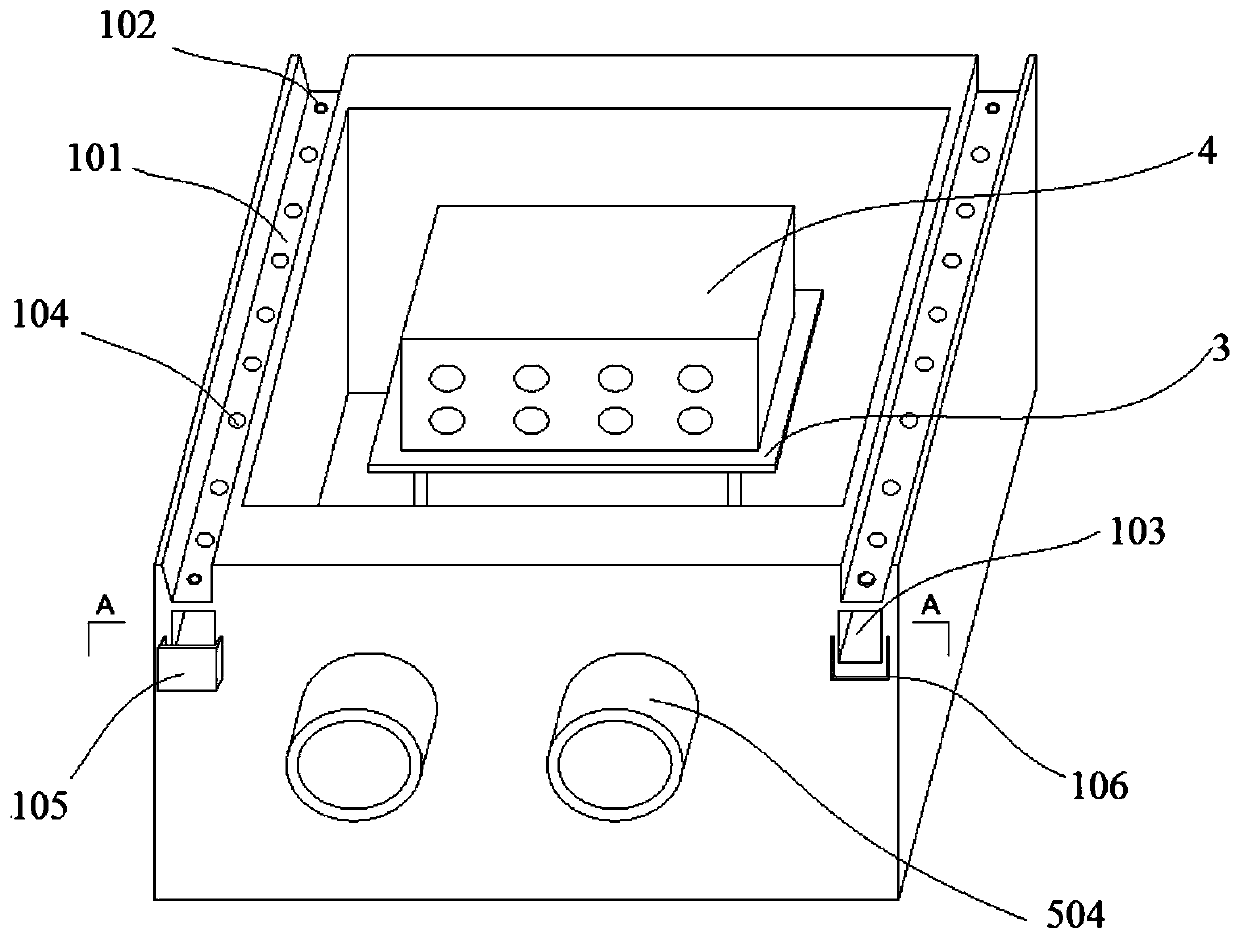

[0030] Electrical junction boxes with improved shell structures, such as figure 1 , figure 2 as well as Figure 5 As shown, including the box body 1 and the box cover 2, the upper end surface of the box body 1 and the two sides along the width direction of the box body 1 are provided with a groove 101 with a wide top and a narrow bottom. The longitudinal section of the groove 101 is a right-angled trapezoid and is close to The side at the center of the box body 1 is a right-angled surface, and the side away from the center of the box body 1 is an inclined plane, and the inclined plane and the bottom surface of the groove 101 form an angle of 100-140°, which is 105° in this embodiment; Be provided with the protruding line 201 that interferes with the groove 101 on the box body 1, the bottom surface of the groove 101 is provided with the threaded hole 102 that is connected with the box cover 2 through the bolt 202, when connecting, first put the convex bar on the box cover 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com