Methods and systems for additive manufacturing

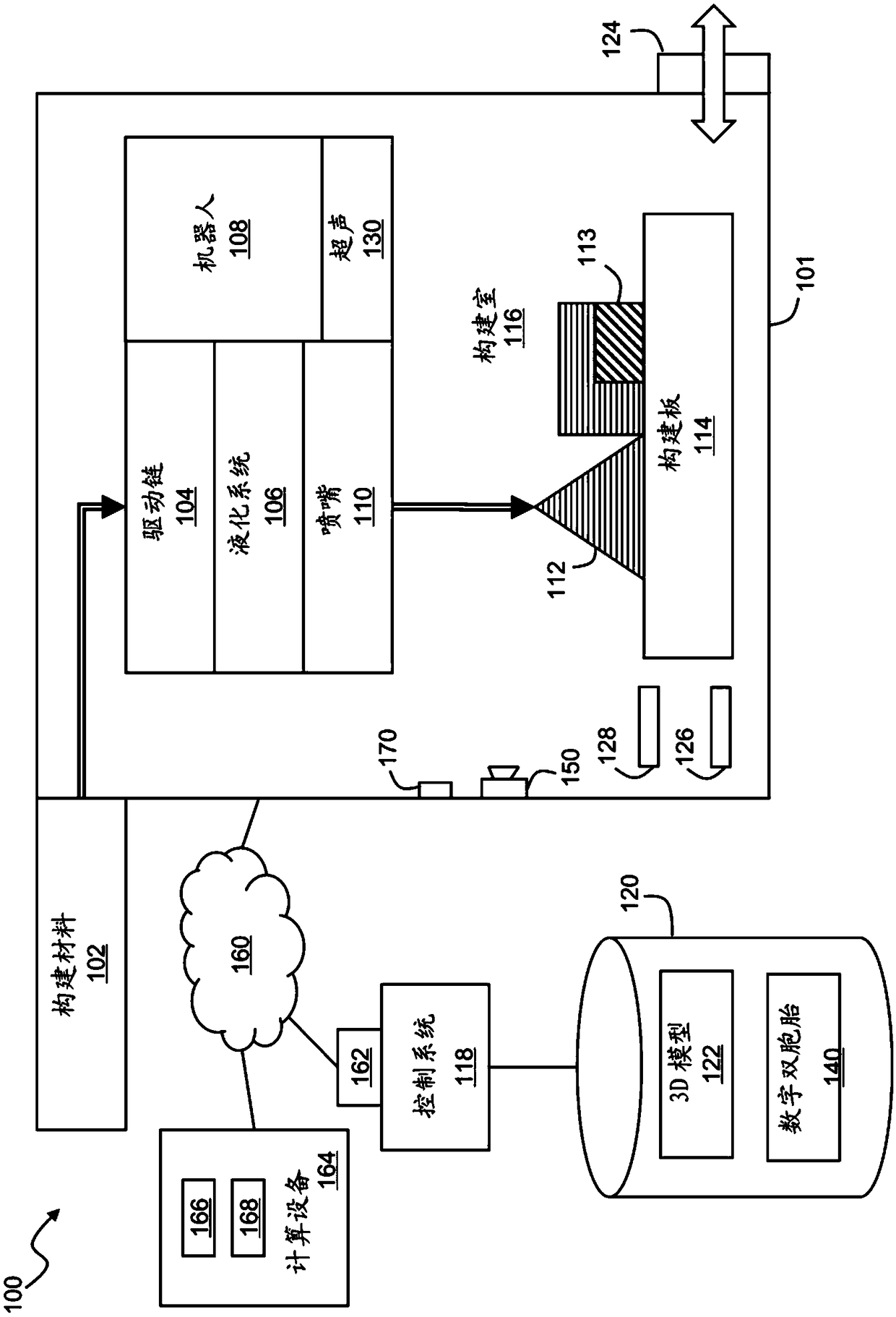

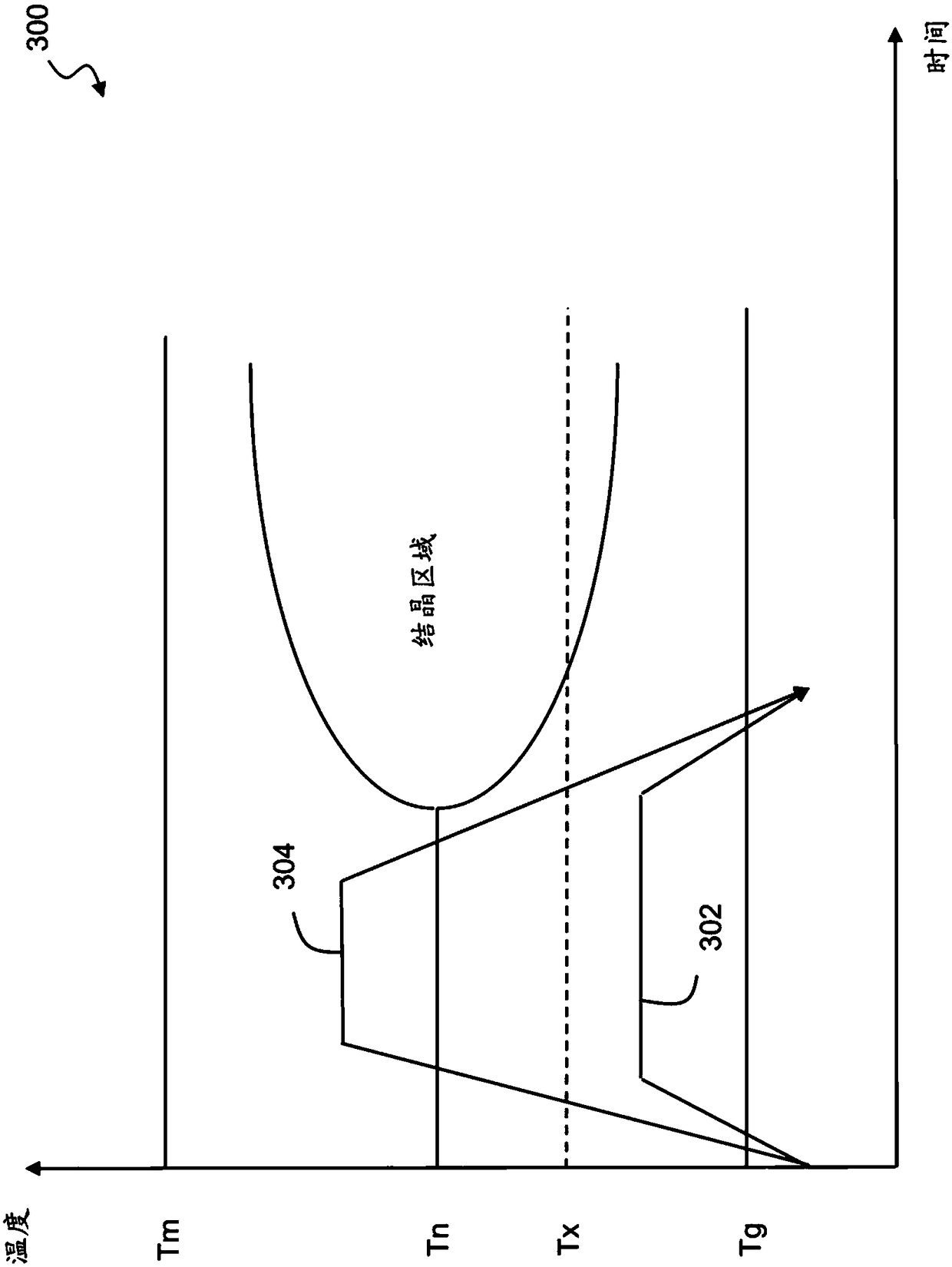

A technology of three-dimensional manufacturing and controller, applied in the field of additive manufacturing, which can solve the problems that physical principles are not applicable to metal-based systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

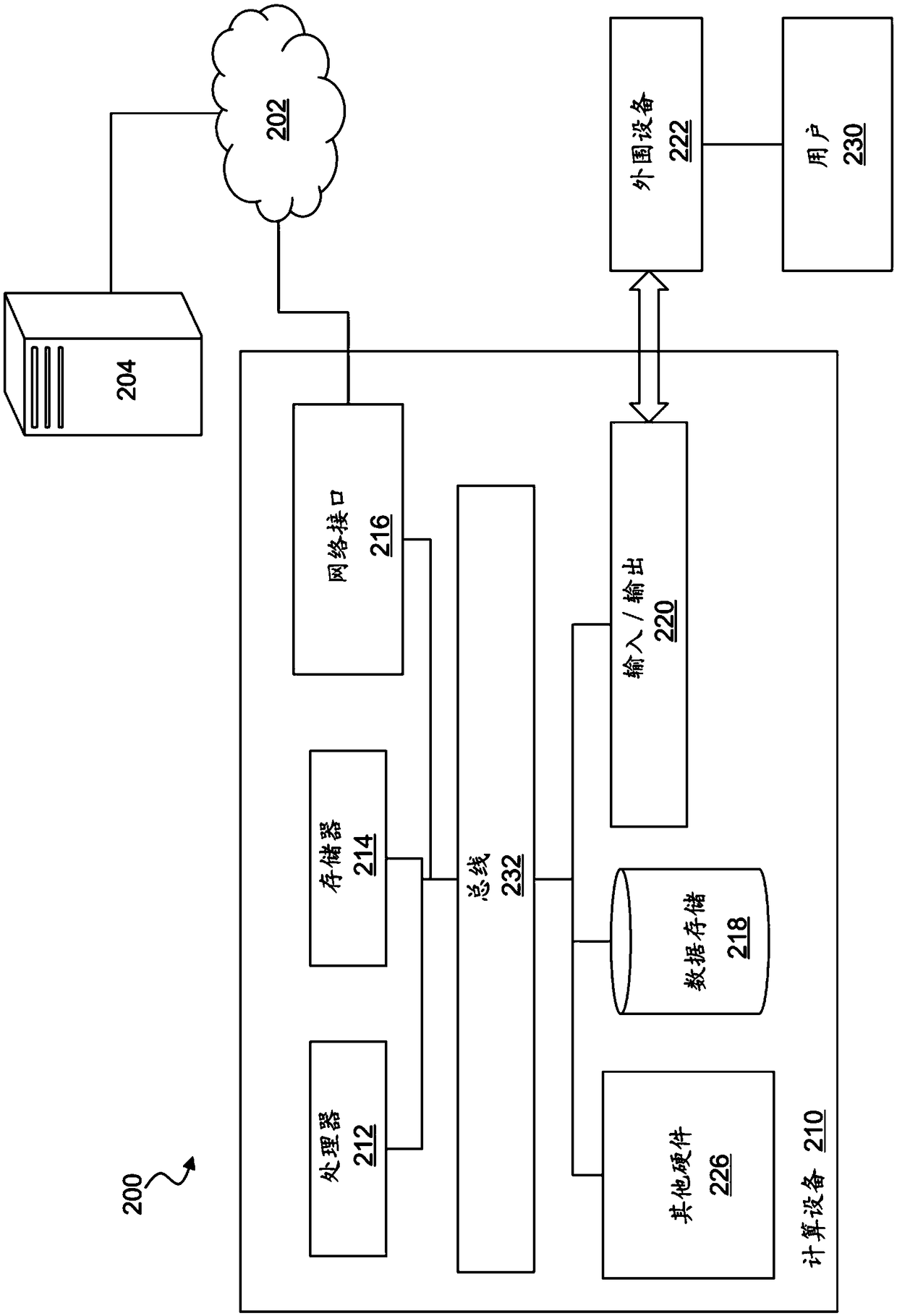

Embodiment Construction

[0067] Embodiments will now be described more fully hereinafter with reference to the accompanying drawings, in which preferred embodiments are shown. However, the foregoing may be embodied in many different forms and should not be construed as limited to the illustrated embodiments set forth herein.

[0068] All documents mentioned herein are incorporated by reference in their entirety. Unless expressly stated otherwise or clear from context, references to singular items shall be understood to include plural items and vice versa. Unless otherwise stated or clear from context, grammatical conjunctions are intended to express any and all inflectional and connecting combinations of connected clauses, sentences, words, etc. Thus, the term "or" should generally be read to mean "and / or" and the like.

[0069] Recitations of ranges of values herein are not intended to be limiting, but instead refer individually to any and all values falling within that range, unless otherwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com