Heat exchanger assembly and method for operating a heat exchanger assembly

A technology for heat exchangers and components, applied in heat exchange equipment, semiconductor/solid-state device components, electric solid-state devices, etc., to achieve the effect of reducing the amount of space and using efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

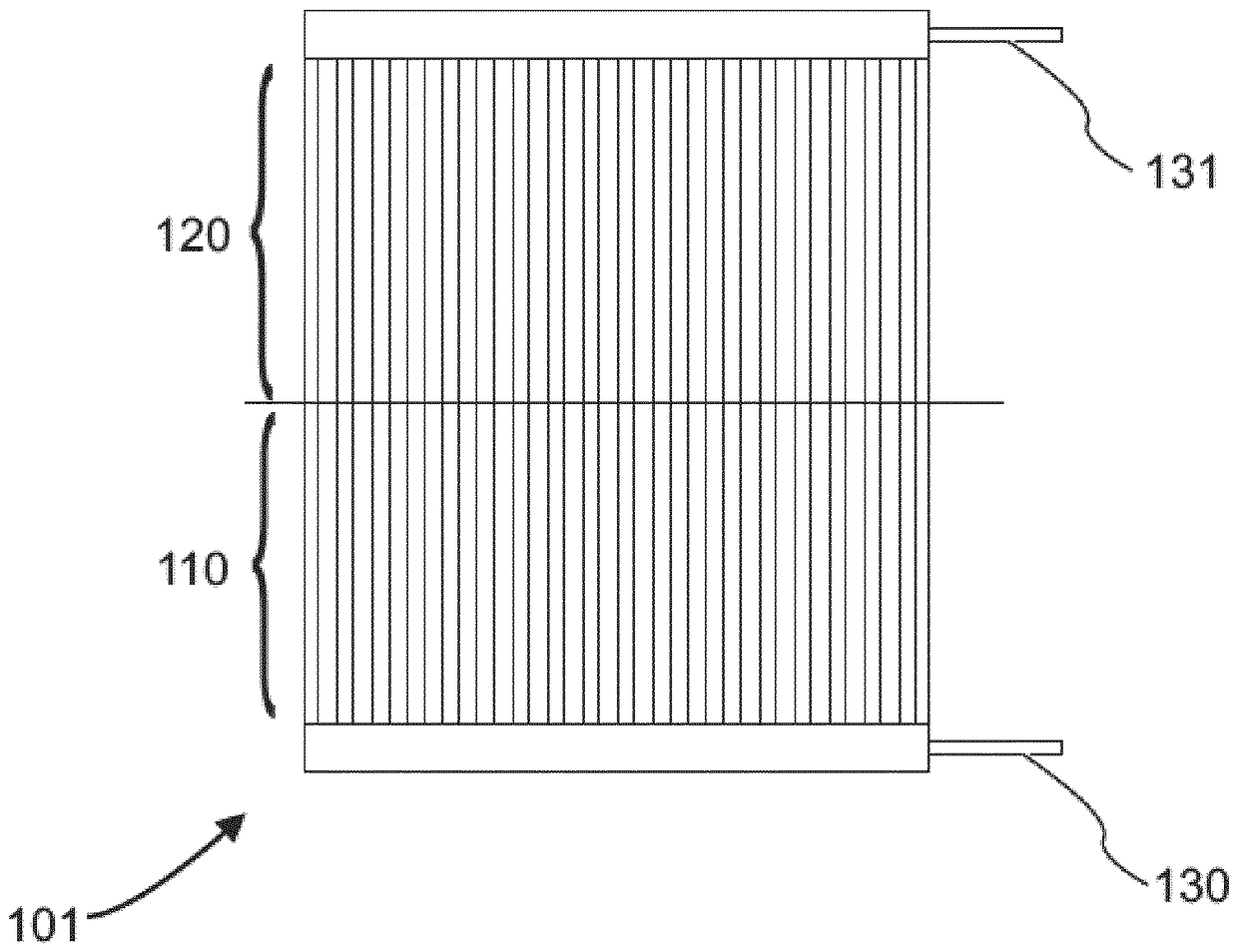

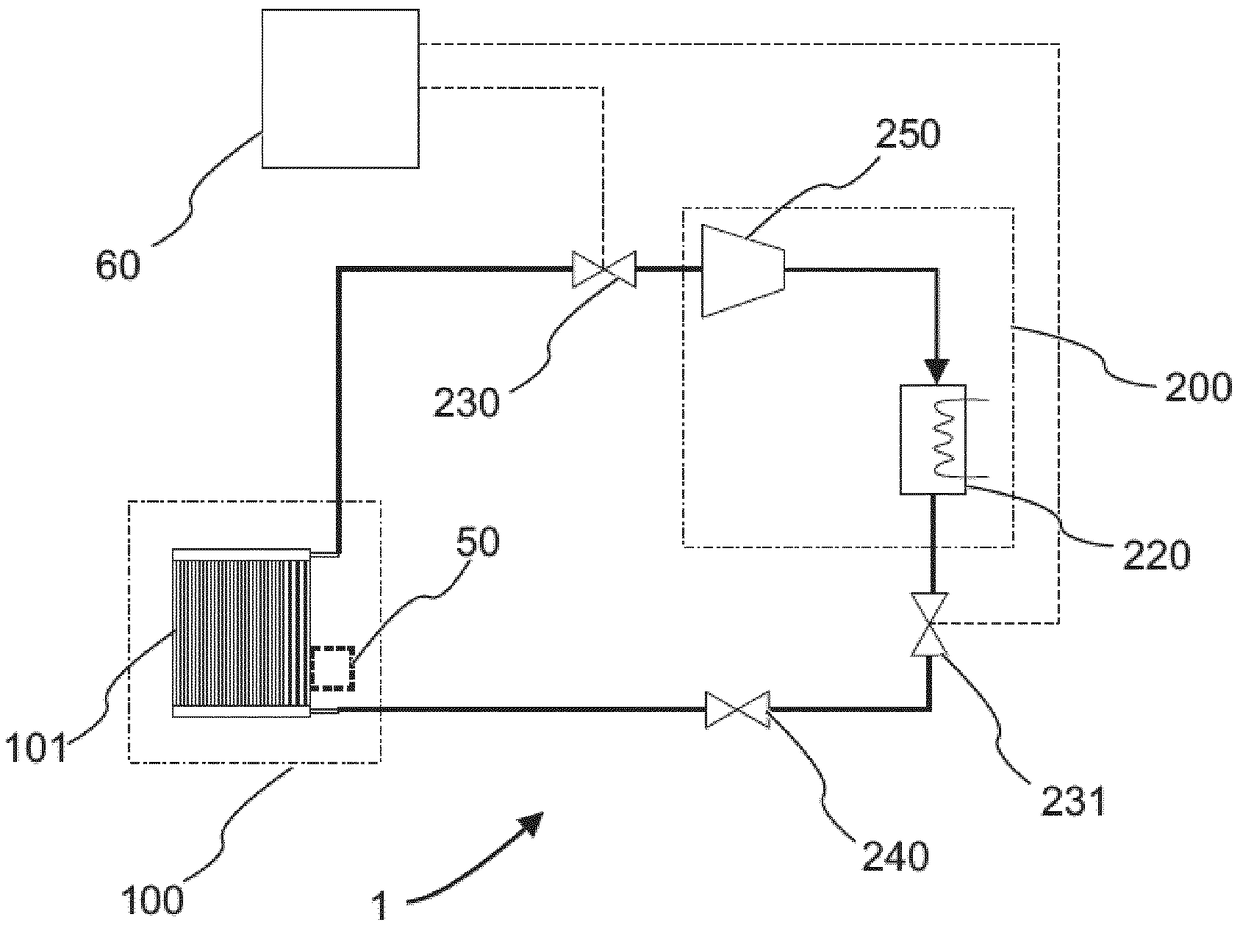

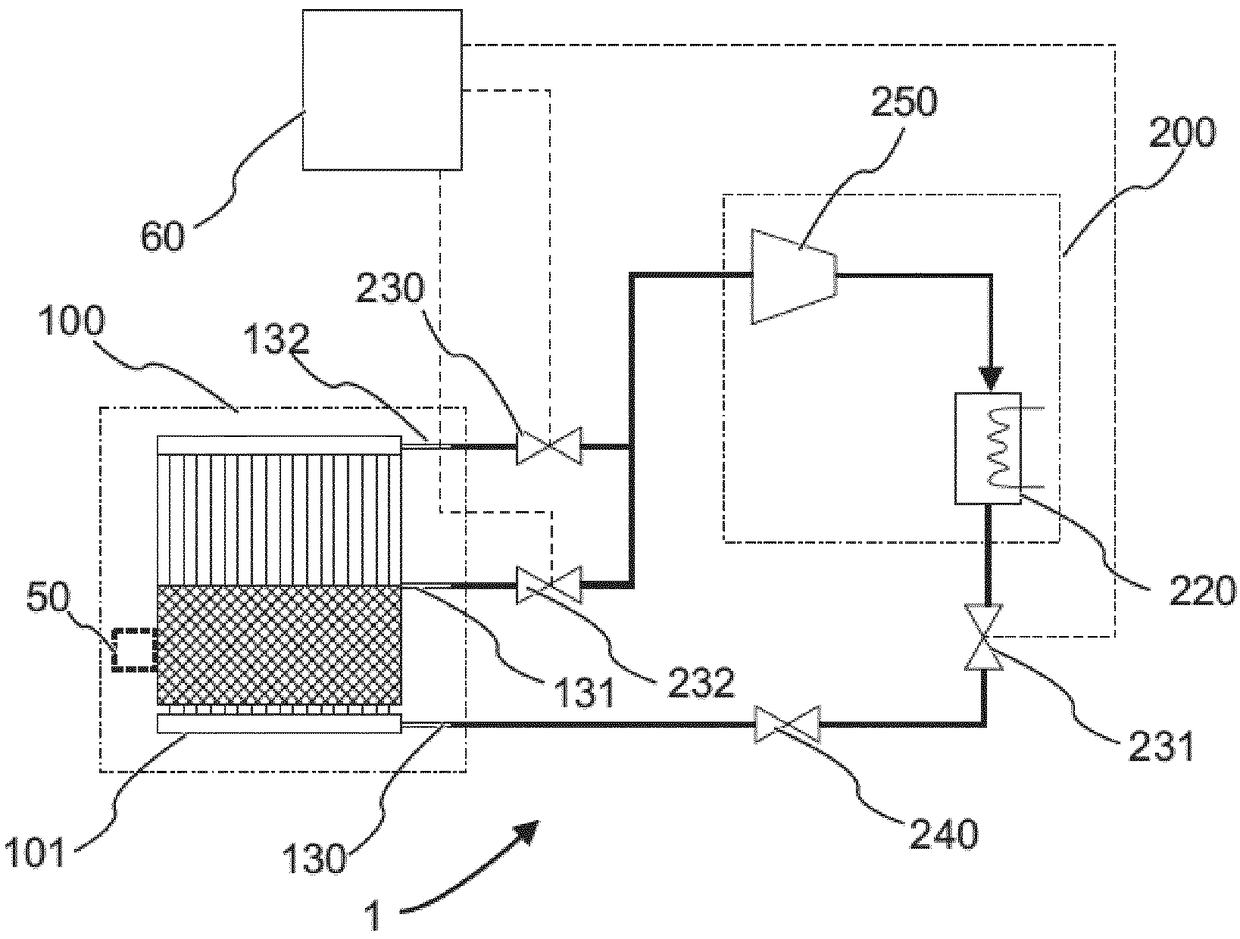

[0027] In the following, various aspects and features of embodiments of the present disclosure are described. It is intended that various aspects and features may be combined with any other aspect or feature whether or not described in the context of a particular embodiment.

[0028] In the figures and the description of the embodiments, in principle identical or corresponding parts are provided with the same reference numerals. Descriptions relating to the same reference surface shall be applicable to any embodiment unless otherwise specified.

[0029] figure 1 Graph showing ambient temperature and operating power of an electronic component cooled by a prior art cooling device. In this cooling arrangement, a passive cooling circuit, such as a thermosiphon, is used.

[0030] On the horizontal axis of the graph, the operating ranges R1 , R2 and R3 are shown, while on the longitudinal axis the ambient temperature T surrounding the electronic components and the operating power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com