Feed grinding equipment for farm breeding

A feed and farm technology, applied in the direction of feed, application, mixer, etc., can solve the problems of single function, affecting the use of feed, single and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

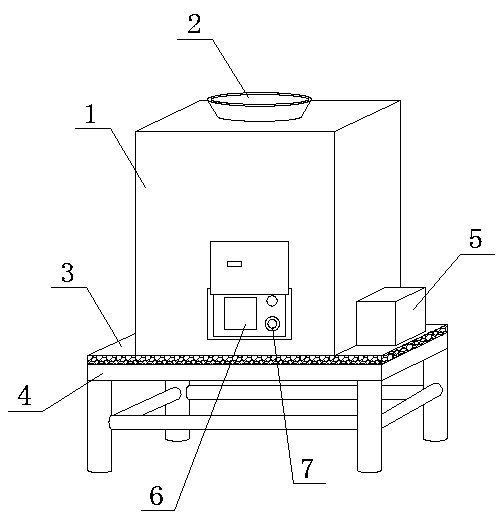

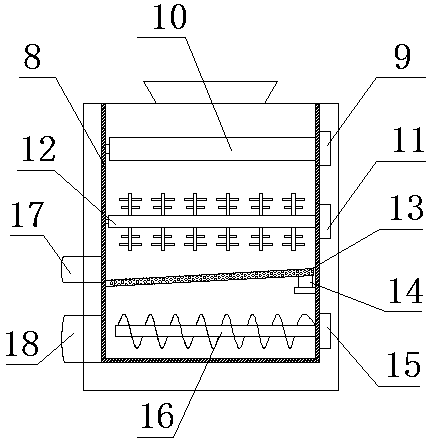

[0024] Example: see Figure 1-4 , the present invention is a feed crushing equipment for farm breeding, comprising a housing 1, a shock absorbing plate 3, a chassis 4 and an equipment box 5, the middle part of the top of the housing 1 is fixed with a feed inlet 2, and the housing 1. A groove is arranged at the front end, and a display screen 6 is arranged inside the groove, and a power switch and a speed control switch 7 are arranged on the right side of the display screen 6, and a safety cover is arranged on the groove to enhance safety protection. The inner wall of the housing 1 is fixedly connected with the wear-resistant layer 8 made of rubber. The inner upper end of the housing 1 is provided with a roller shaft 10. There are two roller shafts 10. The right side of the roller shaft 10 is connected to the motor A9 is fixedly connected, the inside of the housing 1 is provided with a stirring rod 12 at the lower end of the kun shaft 10, and the upper and lower ends of the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com