Washing machine power supply lower shell mould

A washing machine and power supply technology, which is applied in the field of washing machine power supply lower shell molds, can solve problems such as assembly requirements, buckle injection molding position and shape errors, complex mold structure, etc., and achieve the effect of reducing defective products and avoiding waste of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

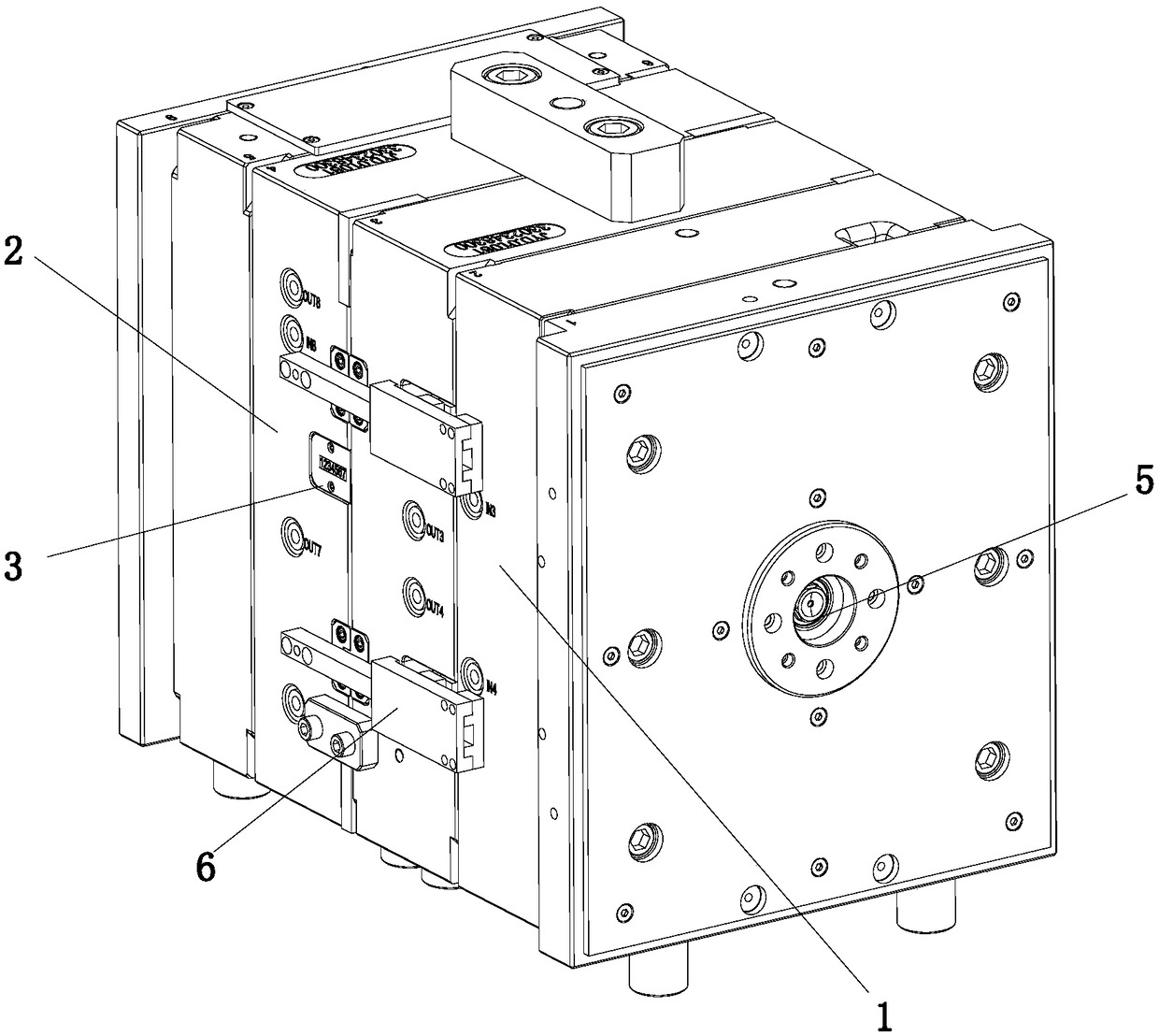

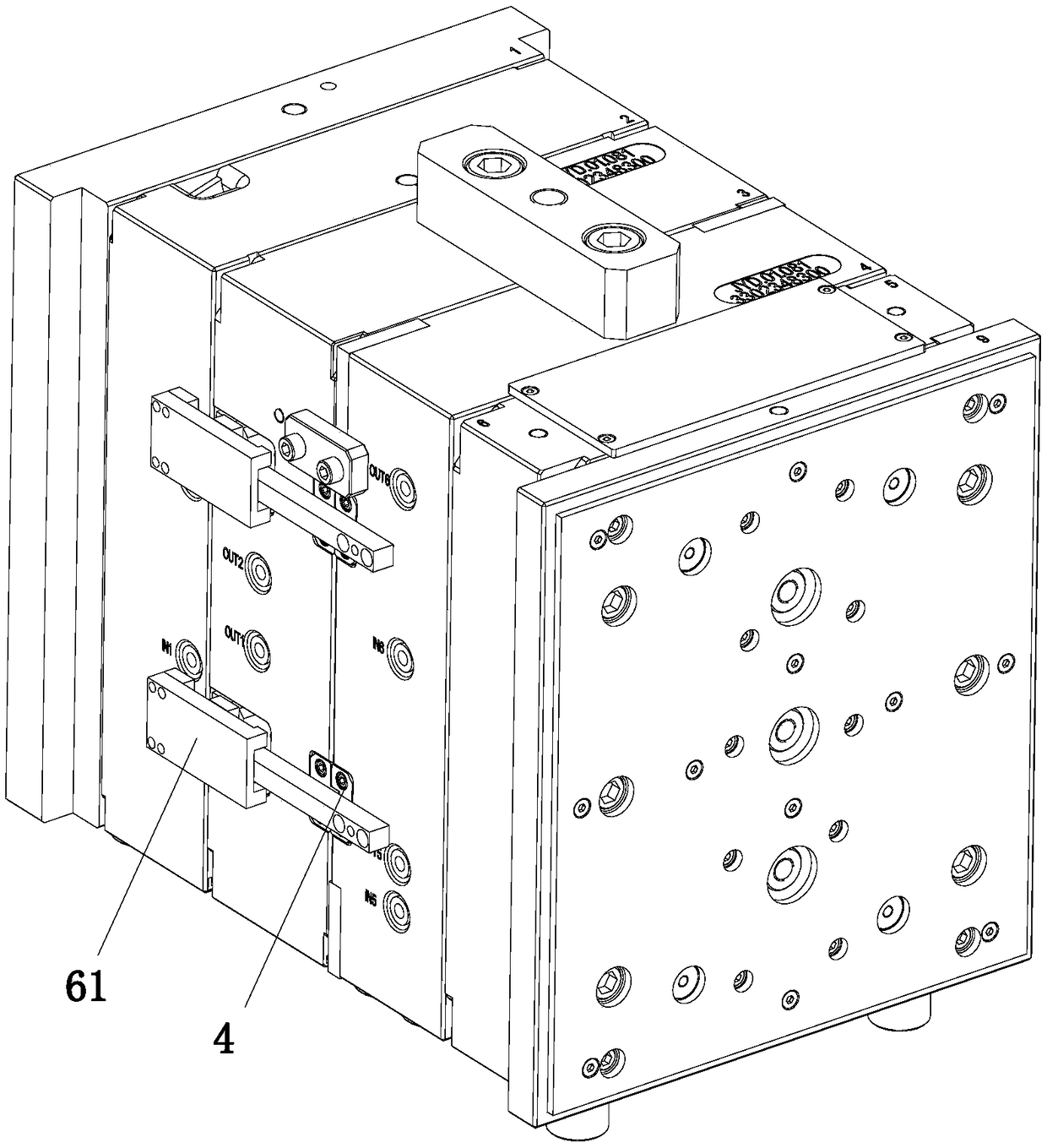

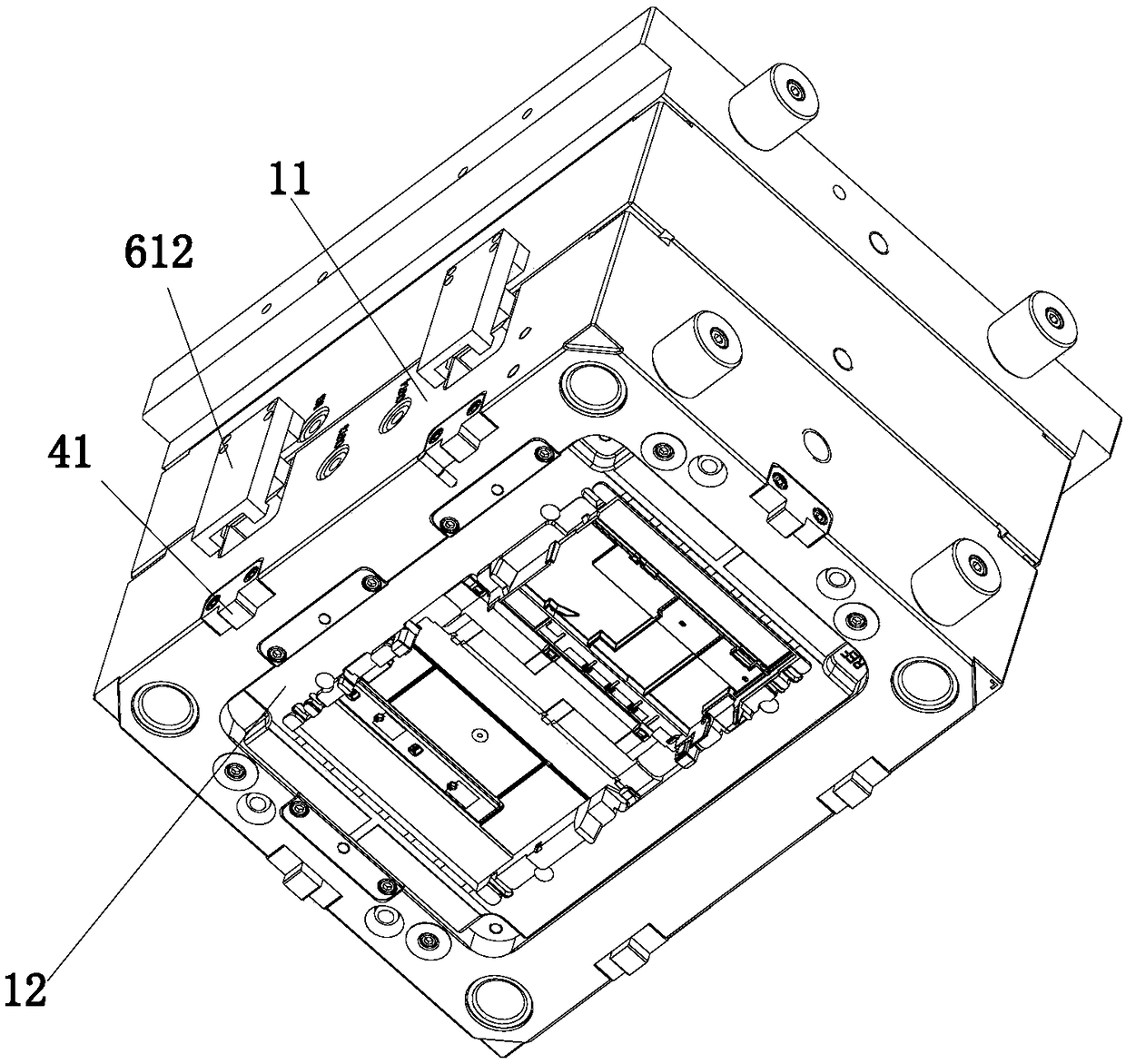

[0019] refer to Figure 1 to Figure 5 The mold for the lower shell of a washing machine power supply shown includes a movable mold 1, a fixed mold 2, an orientation mechanism 6 and a control device. The movable mold 1 can move in opposite directions relative to the fixed mold 2. The movable mold 1 includes a movable mold Template 11 and first mold core 12, the first mold core 12 is arranged on the movable template 11, the fixed mold 2 includes a fixed template 21 and a second mold core 22, and the second mold core 22 is installed on the fixed template 21 Above, the orientation mechanism 6 includes several guide assemblies 61 distributed around the circumferential direction of the mold 1 at intervals, and the first mold core 12 can be attached to the second mold core 22 to form several mold cores for forming the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com