Installation structure for fixing component, heating body assembly and heating device

A technology of installation structure and heating device, applied in the direction of circuit arrangement, heating element material, elastic/clamping device, etc. on the support structure, can solve the problem of axial shaking of the thermostat, prevent left and right rolling, avoid shaking, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

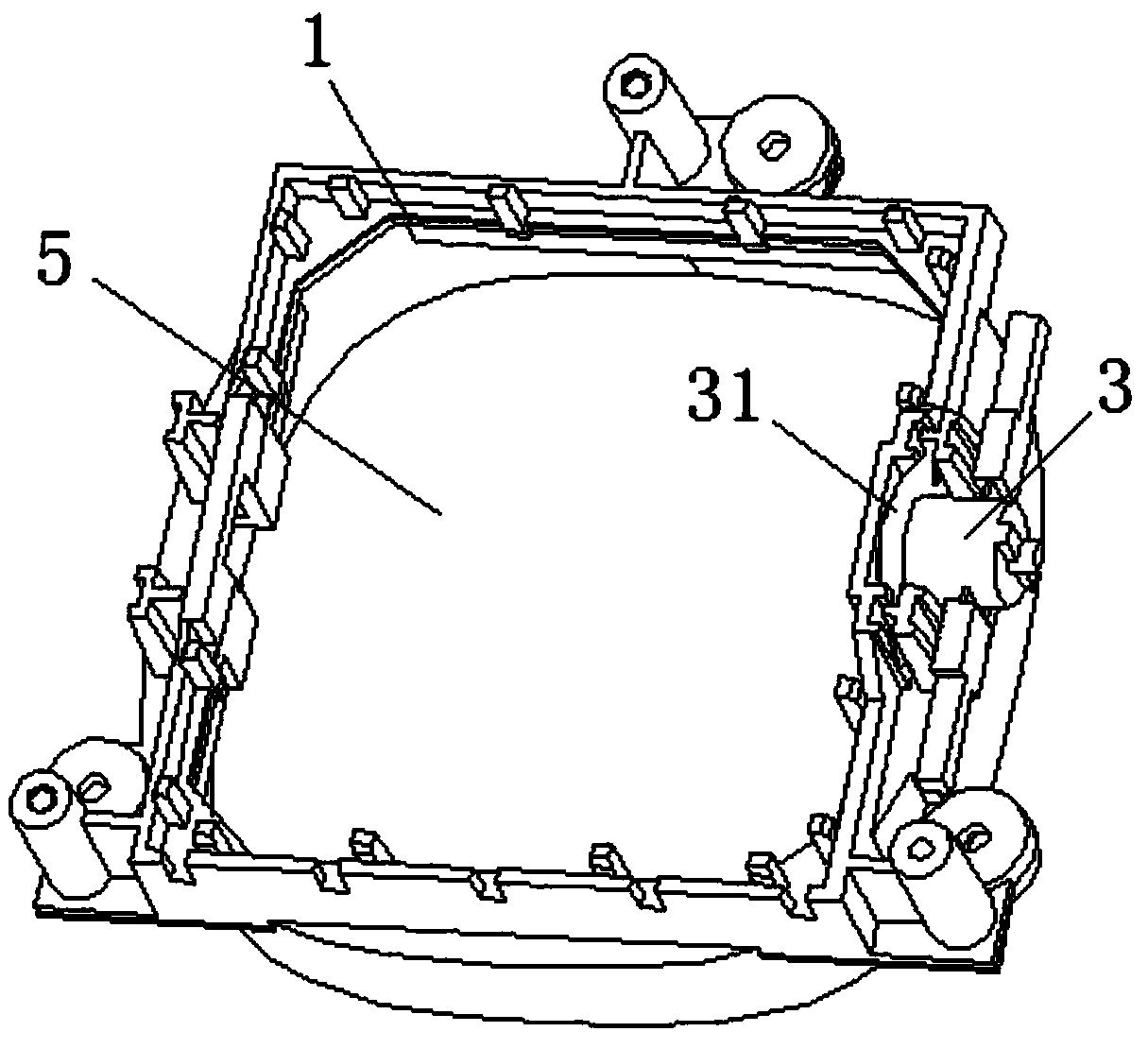

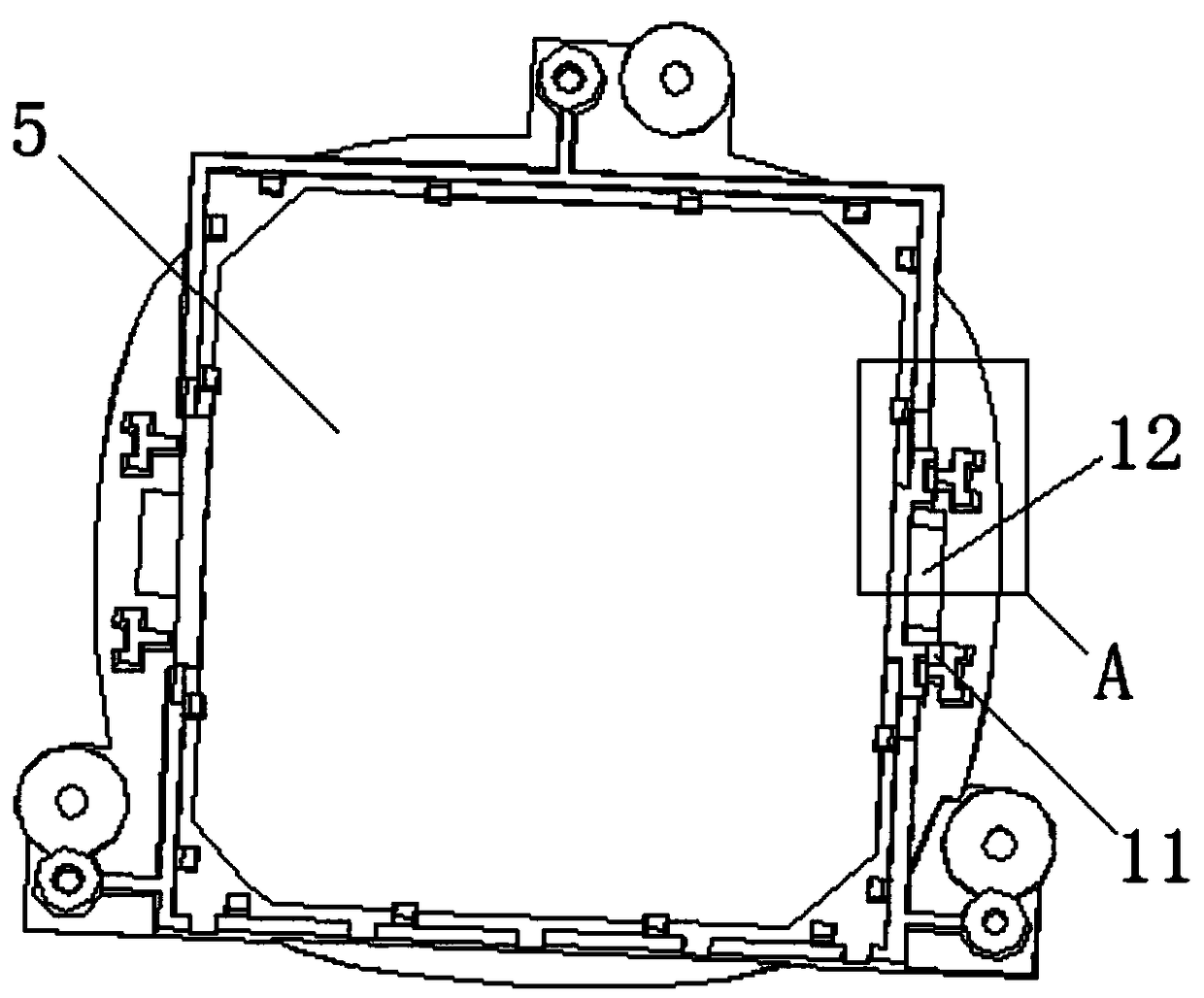

[0048] This embodiment provides a mounting structure for fixing components, such as Figure 2~4As shown, it includes a first connecting piece 1 and a fixing ear 31; the first connecting piece 1 has a limiting groove 11 for accommodating components, and on both sides of the limiting groove 11 are provided The slot 111, the fixing ear 31 is connected to the component, and has a sheet-shaped structure protruding from at least two side wings of the component. After the component is placed in the limiting groove 11, the fixing The sheet-shaped structures of the two side wings of the ear 31 are snapped into the bent grooves 111 on both sides of the limiting groove 11 through elastic deformation.

[0049] In the above installation structure for fixing components, after the fixing ears connected to the components are inserted into the channel, the fixing ears will be elastically deformed in the bent channel 111, so that the channel 111 is axially aligned with the fixing ears 31. Lock...

Embodiment 2

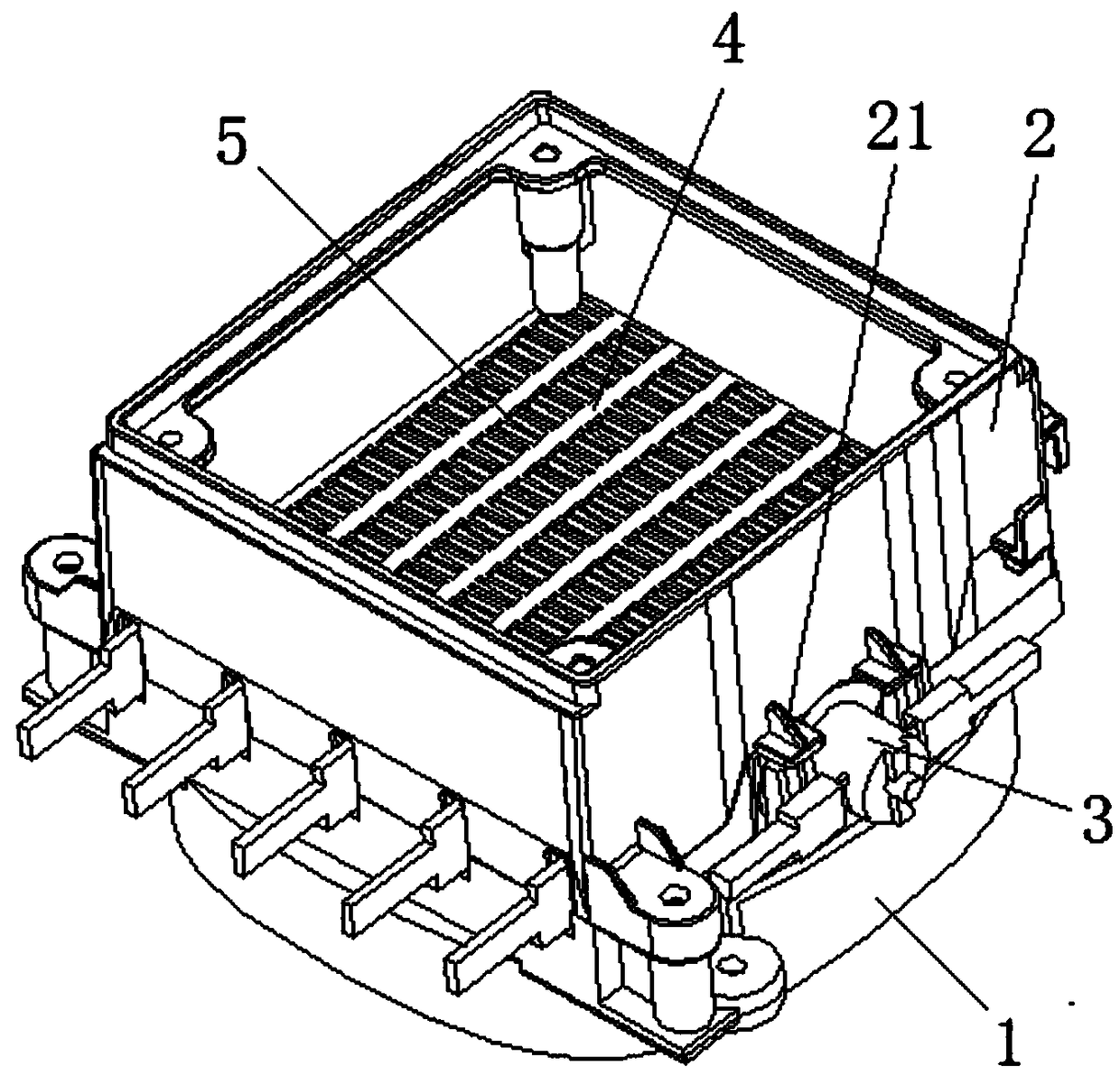

[0060] This embodiment provides a heating element assembly, such as Figure 1~4 As shown, it includes the installation structure described in the above-mentioned embodiment 1, wherein the component is a temperature limiter 3; the first connector 1 and the second connector 2 are connected to form a hollow structure The housing, the hollow part of the housing is an air flow channel 5 , and the heater 4 is arranged in the air flow channel 5 .

[0061] The above-mentioned heating element assembly can install the temperature limiter 3 at the same time when the heater 4 is installed, and the temperature limiter is fixed through the above-mentioned installation structure, which solves the problem of low efficiency when fixing the traditional threaded connector, and saves thread The cost of the connecting piece, and also has any of the advantages of the above-mentioned installation structure.

[0062] Specifically, there are multiple heaters 4, and multiple heaters 4 are evenly arran...

Embodiment 3

[0065] This embodiment provides a heating device, including the heating element assembly described in Embodiment 2 above.

[0066] Specifically, the heating device is a warm air dryer.

[0067] In addition, the heating device may also be other equipment than the warm air dryer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com