Stirring device used for ink processing

A technology of stirring device and ink, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc., can solve problems such as loud noise and device displacement, and achieve noise avoidance, displacement avoidance, and force dispersion. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

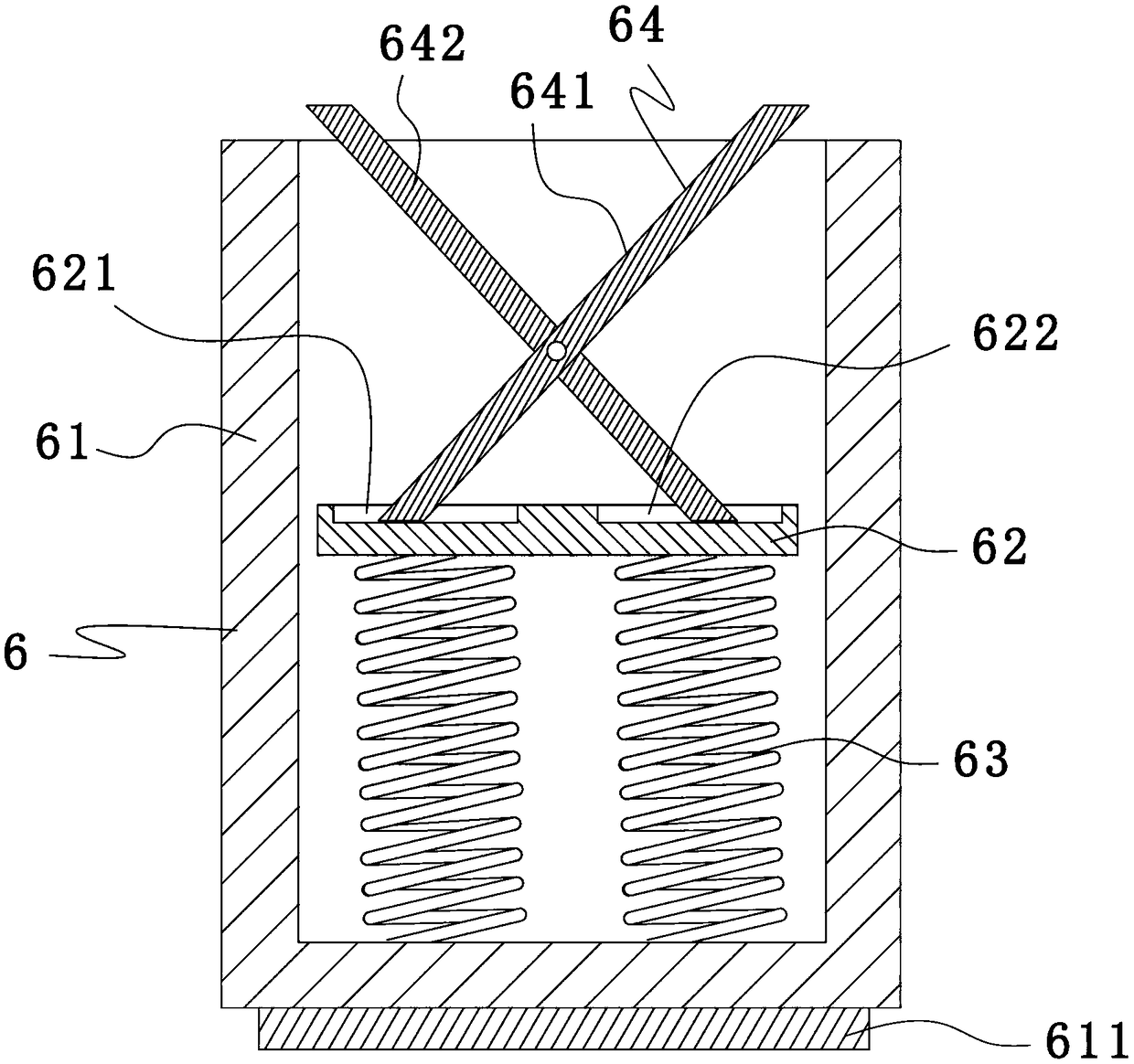

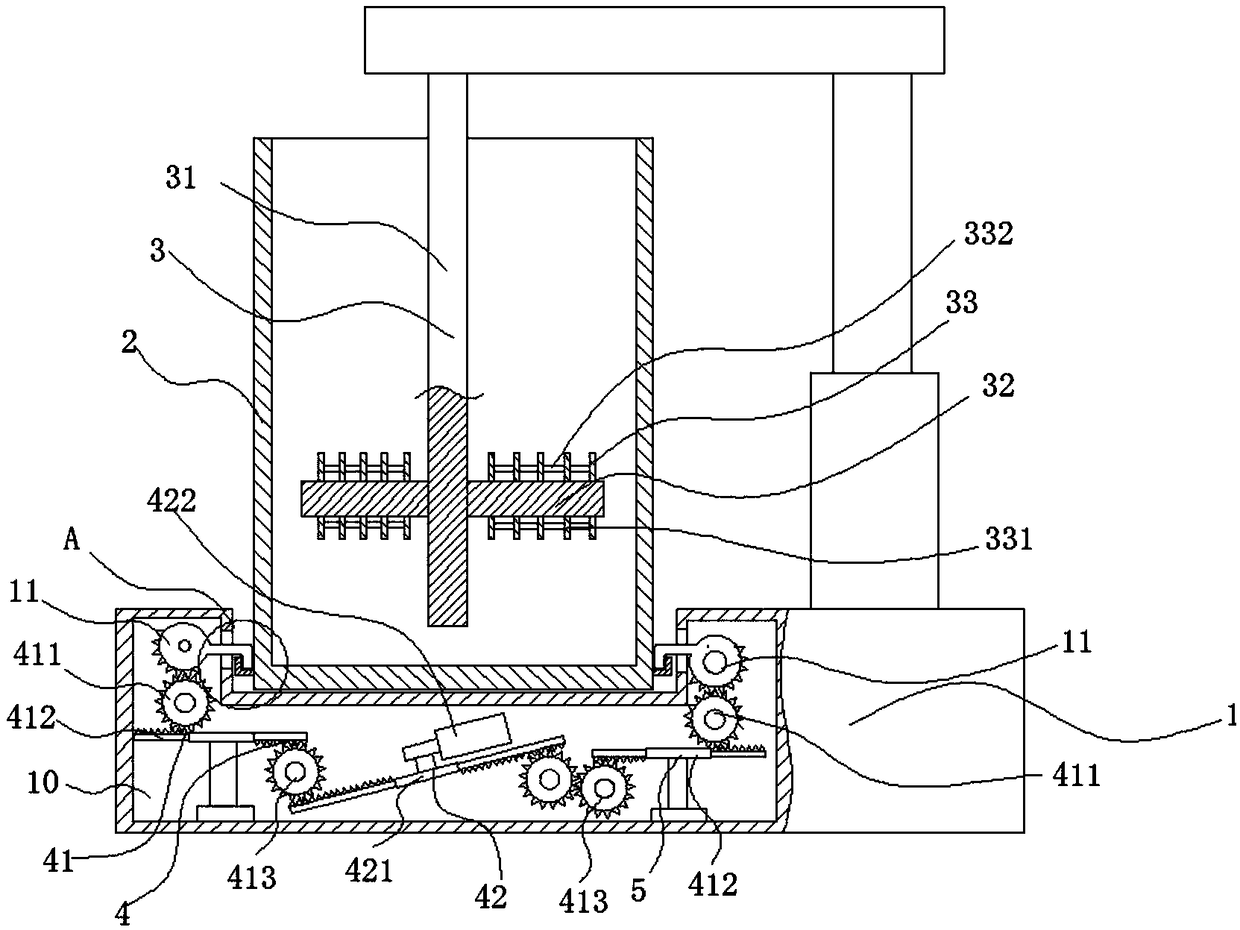

[0019] Such as Figure 1-5 As shown, a stirring device for ink processing includes a base 1, a stirring chamber 2 and a stirring member 3, the base 1 is a metal plate, and the stirring chamber 2 is a metal bucket; on the outer wall of the stirring chamber 2 A clamping part 21 is provided on the top, and the clamping part 21 is a circle of metal rings arranged at the lower part of the mixing chamber 2. A clamping groove 211 is provided on the clamping part 21. The clamping groove 211 is A concave ring formed by the upper end of the clamping part 21 being depressed downward; a placement cavity 10 is provided on the base 1, and the mixing chamber 2 is placed in the placement cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com