Bag breaking equipment for building cement bags

A technology for cement bags and construction, which is applied in the field of bag breaking equipment for construction cement bags, can solve problems such as low work efficiency and impact on physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

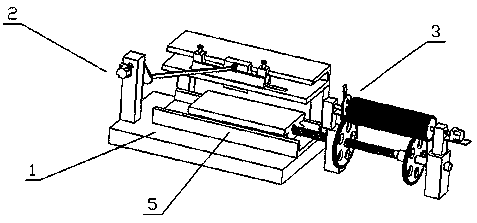

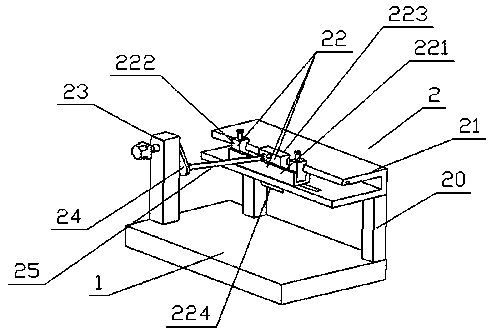

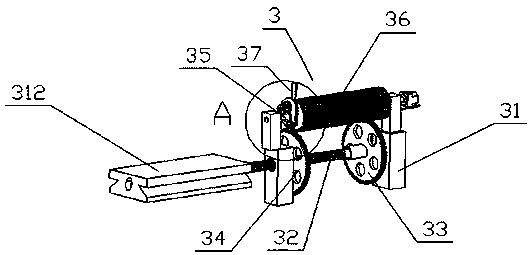

[0029] see Figure 1 to Figure 4 , the present invention is: a bag breaking equipment for cement bags for construction, comprising a bottom plate 1, a cutting mechanism 2 is arranged on the bottom plate 1, and a moving mechanism 3 is arranged on one side of the bottom plate 1;

[0030] Base plate 1 is provided with load-bearing block 20, and cutting mechanism 2 comprises the frame 21 that is arranged on load-bearing block 20, and frame 21 is provided with slide block assembly 22, and slide block assembly 22 comprises slide block 221, and slide block 221 two A baffle 222 is provided at the end, and a driving block 223 is arranged between the baffles 222. The driving block 223 is arranged in the slider 221, and a cutting hole is arranged at the bottom of the slider 221. A cutting knife 224 is arranged at the bottom of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com