360 degree horizontal rotating roller conveyor

A roller conveyor and horizontal rotation technology, applied in the field of conveyors, can solve the problems of rough and inaccurate control of the rotating seat 5, and achieve the effects of accurate angle, timely response and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

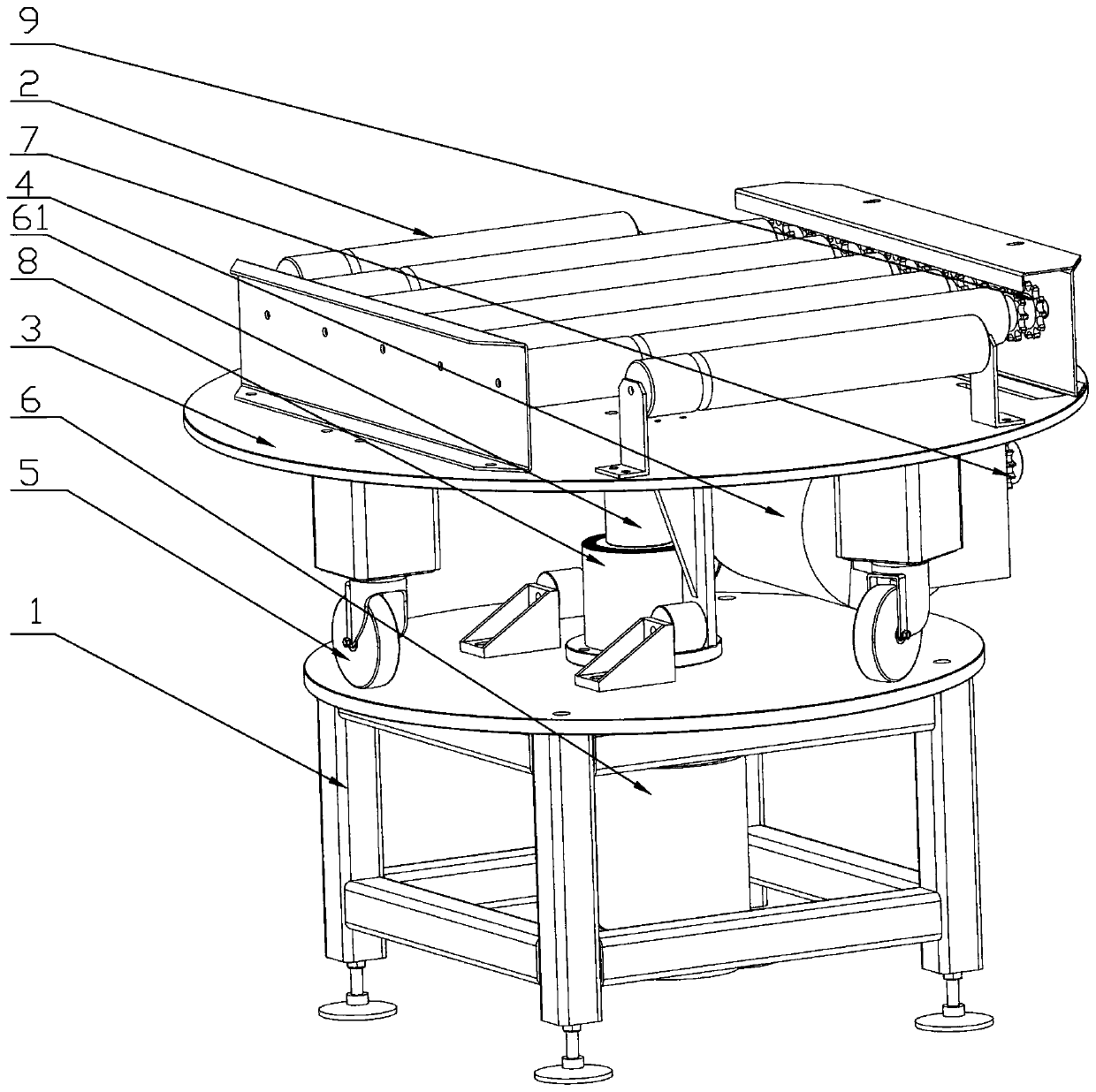

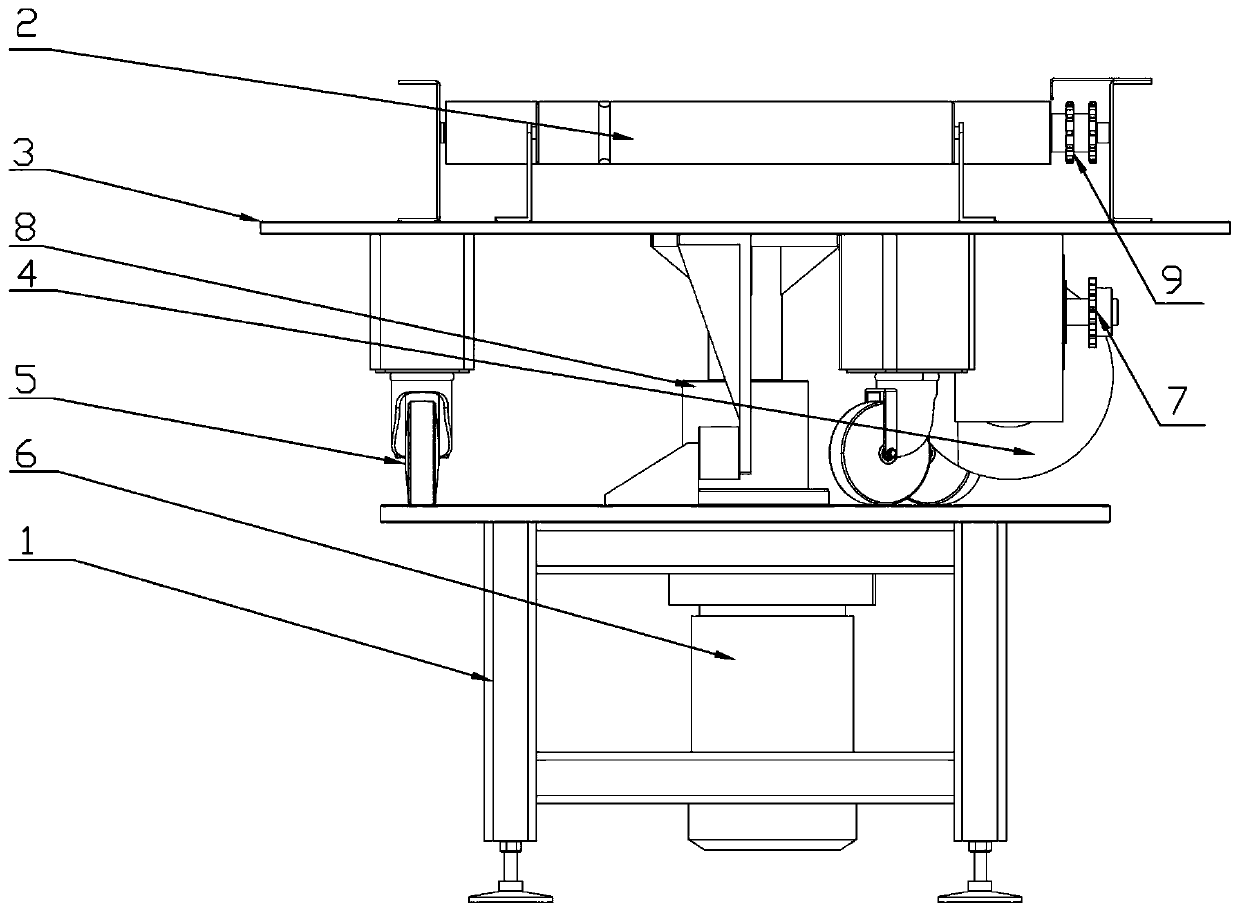

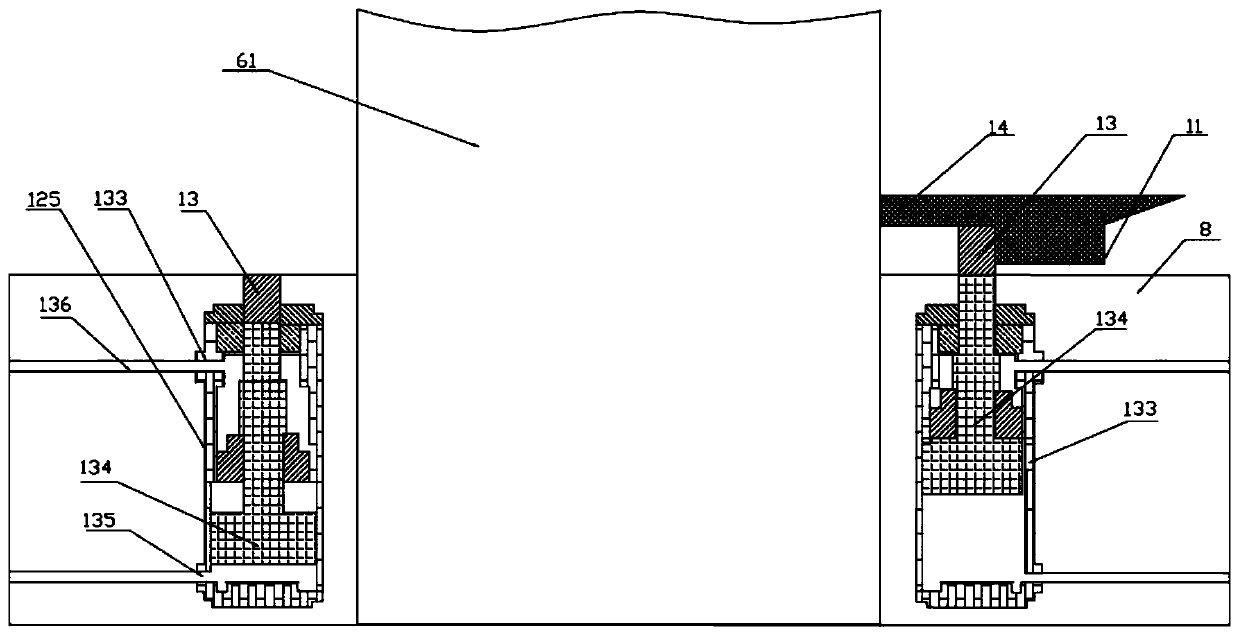

[0024] refer to Figure 1-Figure 4 , 360-degree horizontal rotary roller conveyor, the roller conveyor includes a frame 1, a roller machine 2, a rotating seat 3, a first driving device 4 for driving the roller machine 2, and a second driving device 6 for driving the rotating seat 3 to rotate , in order to be able to indicate each angle of the rotating base 3, the output shaft 61 of the second driving device 6 is fixed with an indicator needle 14 ( Figure 4 shown in ), the periphery of the output shaft 61 of the second driving device 6 has a ring seat 8, the position of the ring seat 8 is fixed, and the outer edge of the ring seat 8 is provided with 360 vertically telescopic baffles 13 , the outer edge of the ring seat 8 is provided with an angle scale 10, and the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com