Sweeper

A sweeping machine and body technology, applied in the field of sweeping machines, can solve the problems of high production cost, complicated structure, and inability to accurately control the water output of the water tank, and achieve the effect of low production cost, accurate water output, and elimination of self-priming water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

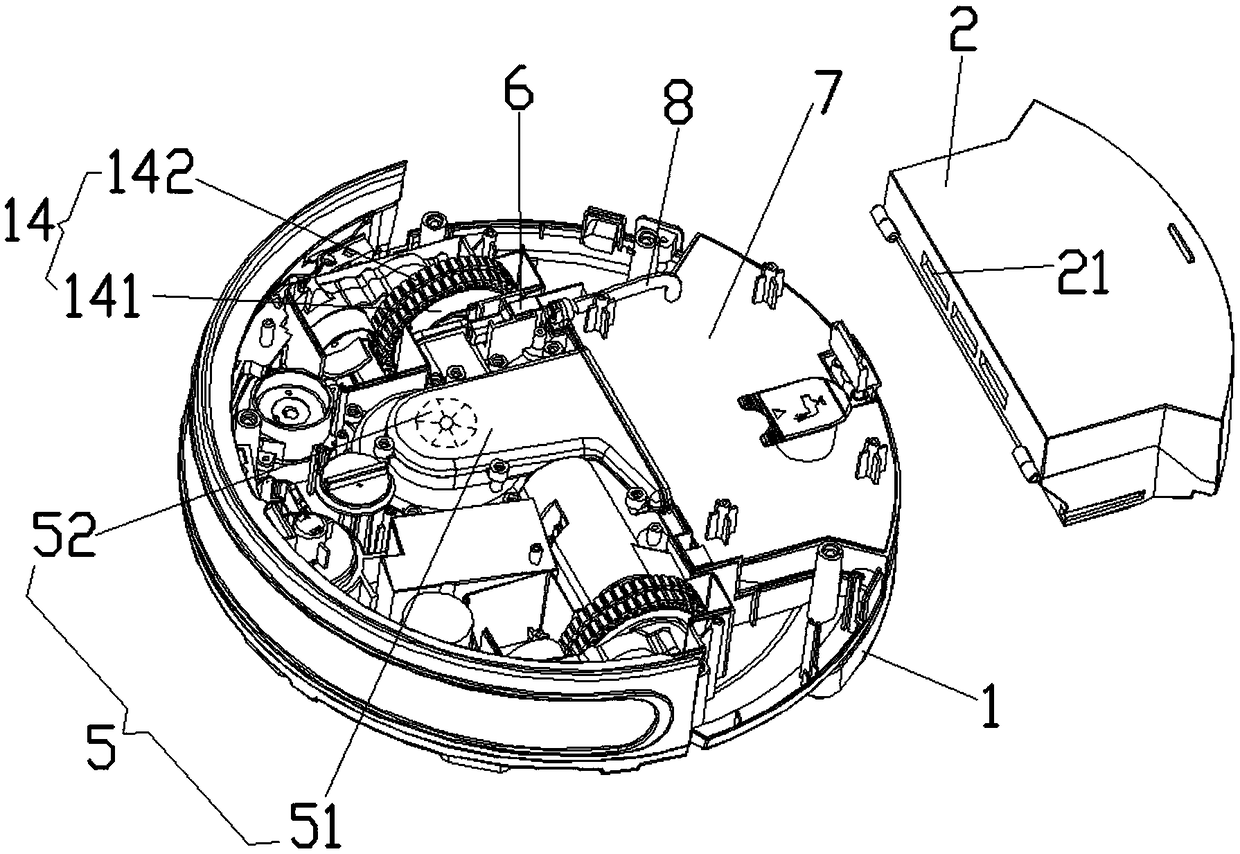

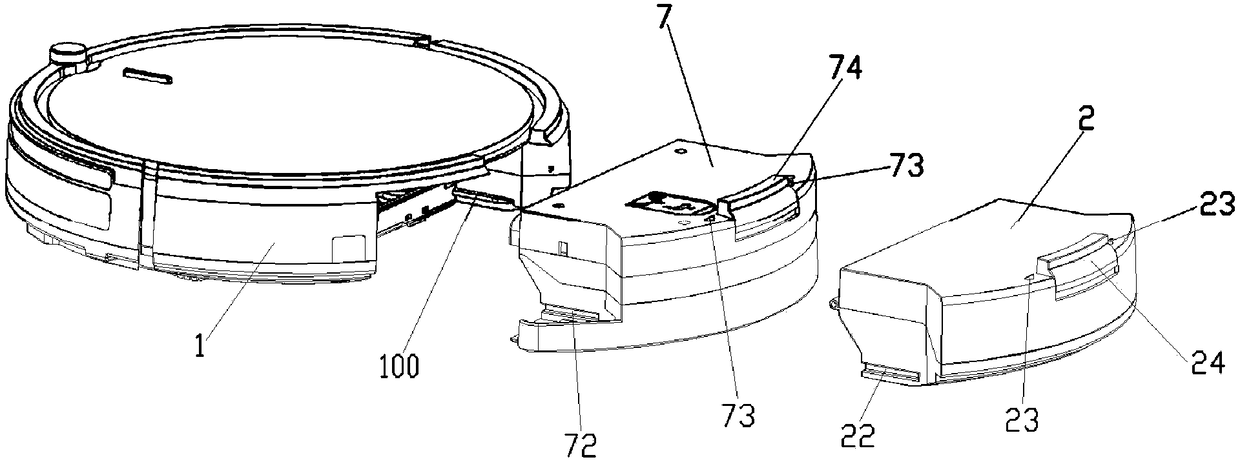

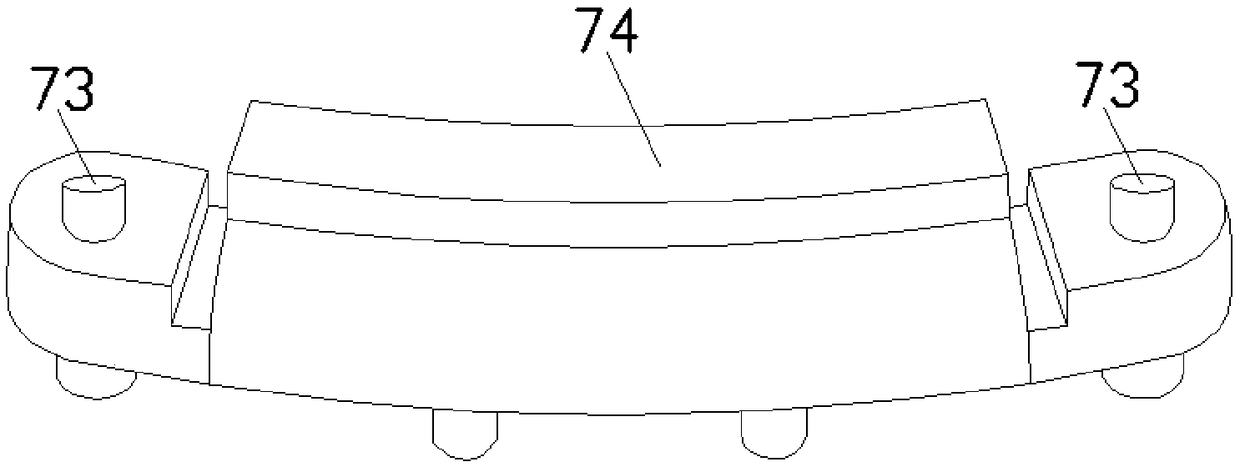

[0034] Such as Figure 1 to Figure 8 As shown, this embodiment provides a sweeping machine body, including a sweeping machine body 1, the bottom of the sweeping machine body 1 is provided with a universal wheel mechanism 13, a driving wheel set and a dust suction port 3, and the sweeping machine body 1 is also provided with an air pump 6 and a power supply for supplying power to the air pump 6. A water tank 7 can also be detachably installed in the sweeper body 1. The air pump 6 is connected to a conduit 8. An air pipe 71 is provided in the water tank 7. , the upper end of the air pipe 71 communicates with the conduit 8, the lower end of the air pipe 71 is close to the bottom wall of the water tank 7 and the lower end of the air pipe 71 has an air outlet, and the bottom wall of the water tank 7 is provided with a capillary outlet hole 9, so that the water in the water tank 7 has a first state that can flow out when the air pump 6 pressurizes the water tank 7, and when the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com