Arrangement for working a tube end

A technology of pipe ends and tools, which is applied in the field of devices for processing pipe ends, and can solve problems such as low power, cylinder damage, and complicated control of hydraulic cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

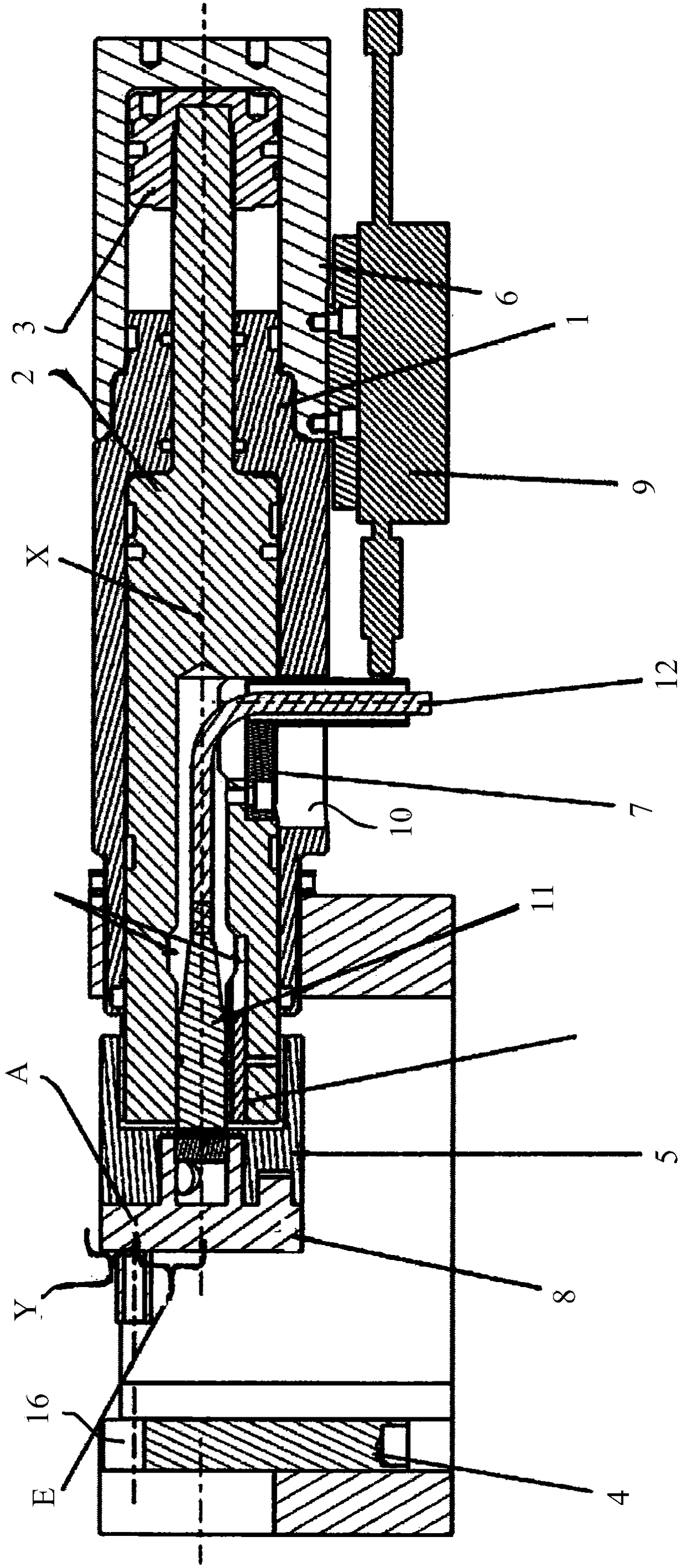

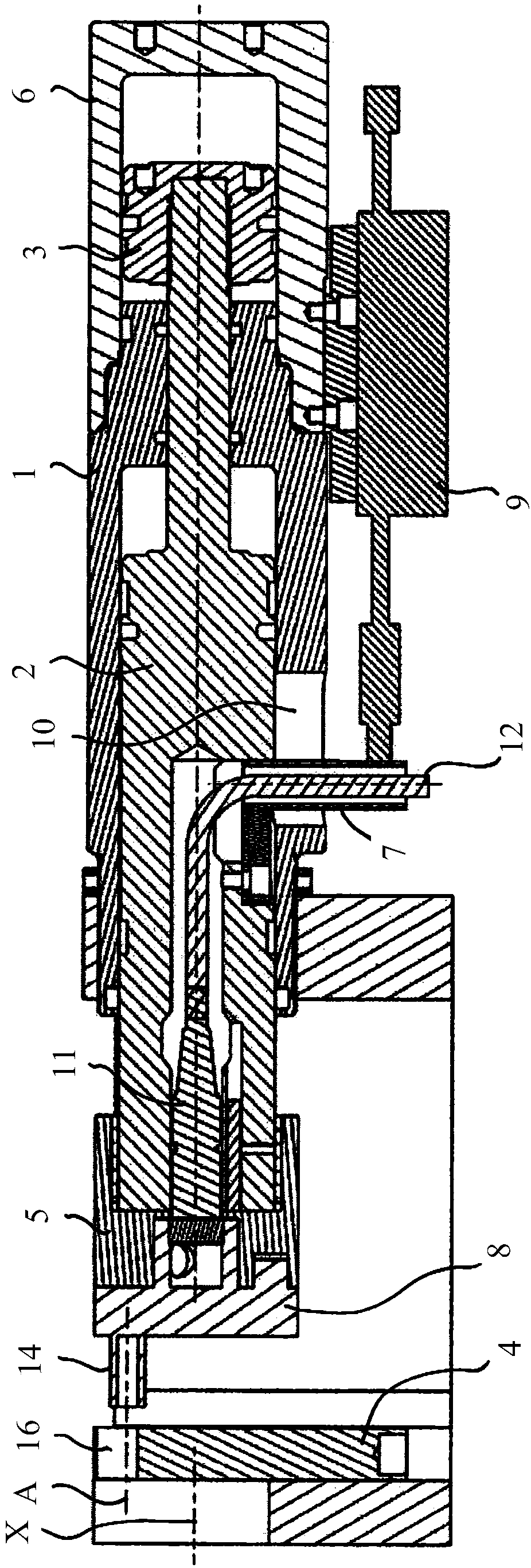

[0018] exist figure 1 with figure 2 In each case is shown a sectional view along the longitudinal axis X of an embodiment of the device for processing pipe ends according to the invention. figure 1 The first machining position is shown, where the pistons 2, 3 are retracted, figure 2 A second machining position is shown, where the pistons 2,3 extend from the operating cylinders 1,6.

[0019] These drawings will be described together.

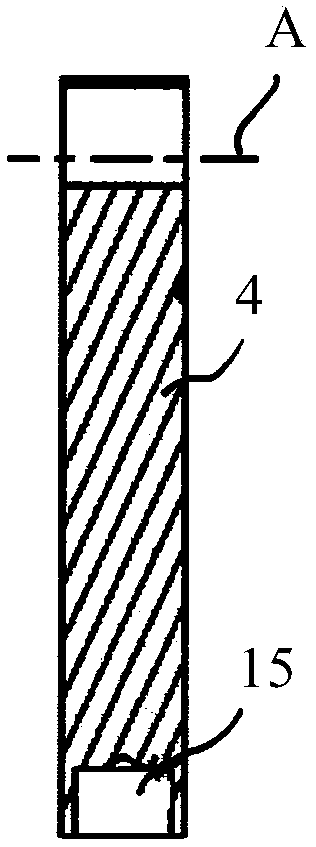

[0020] The pistons 2, 3 are displaceable along the longitudinal axis X, and the tube mount 4 is adapted to fix a tube end (not shown) in such a way that it is axially aligned parallel to the longitudinal axis. A tool holder 5 is provided at the end of the pistons 2 , 3 facing the pipe mounting 4 .

[0021] The operating cylinders 1, 6 are arranged in tandem, wherein the first stage cylinder 1 and the second stage cylinder 6 are arranged staggered along the longitudinal axis X, and the pistons 2, 3 comprise a first piston section connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com