Robot joint module

A technology of robot joints and modules, which is applied in the field of robots, can solve problems such as safety hazards and clutter, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

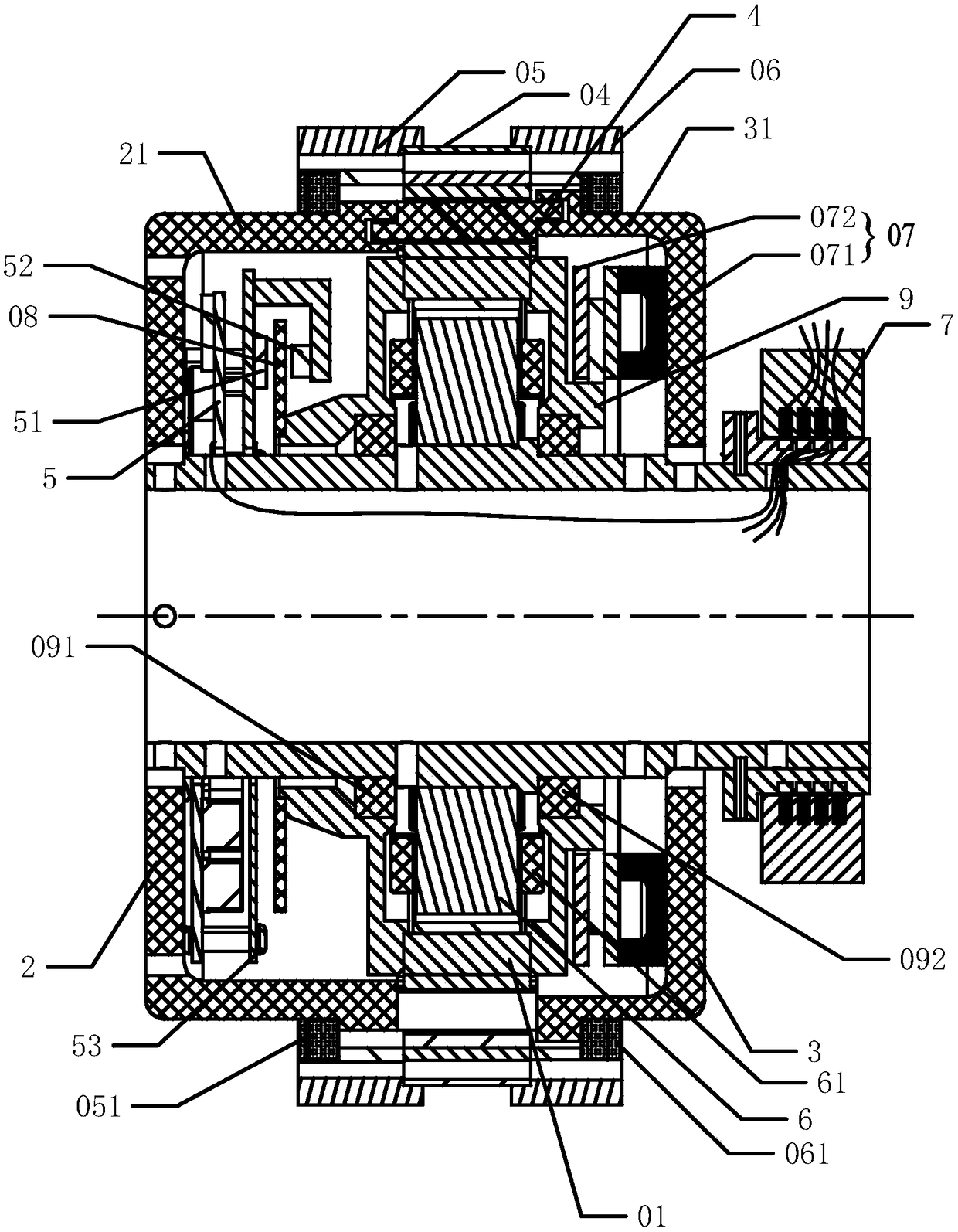

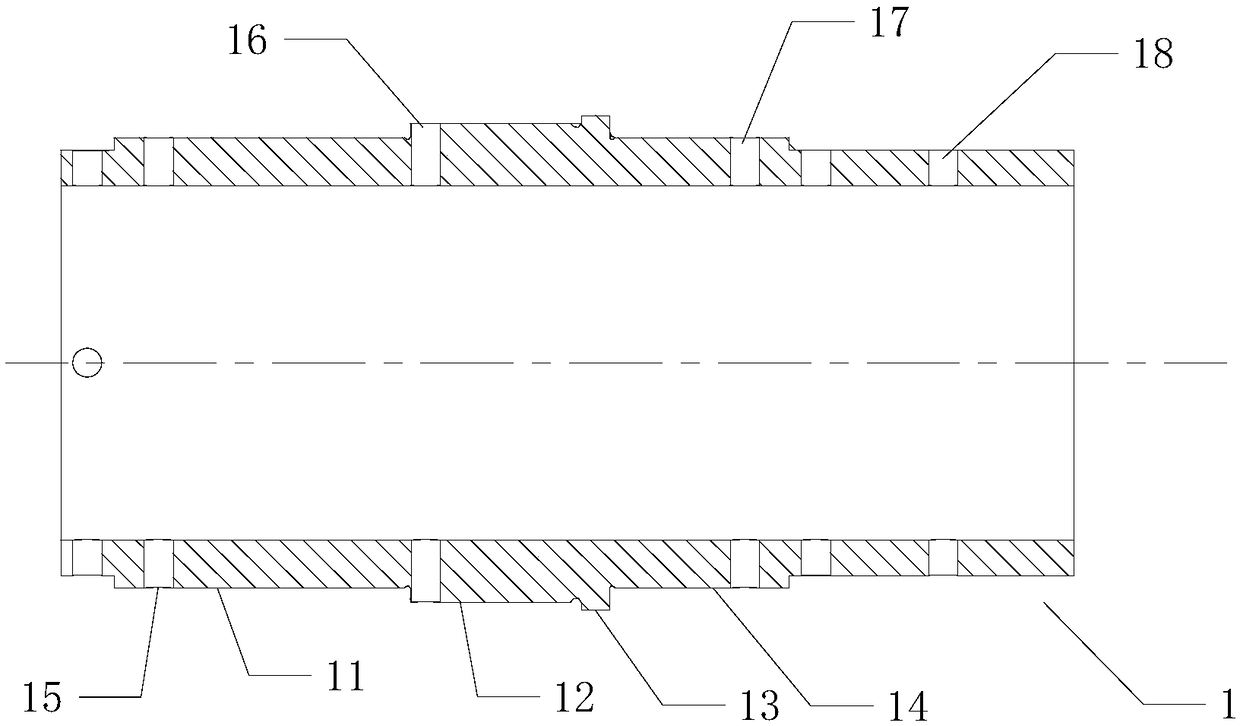

[0052] Attached below Figure 1~3 A robot joint module of the present invention will be further described.

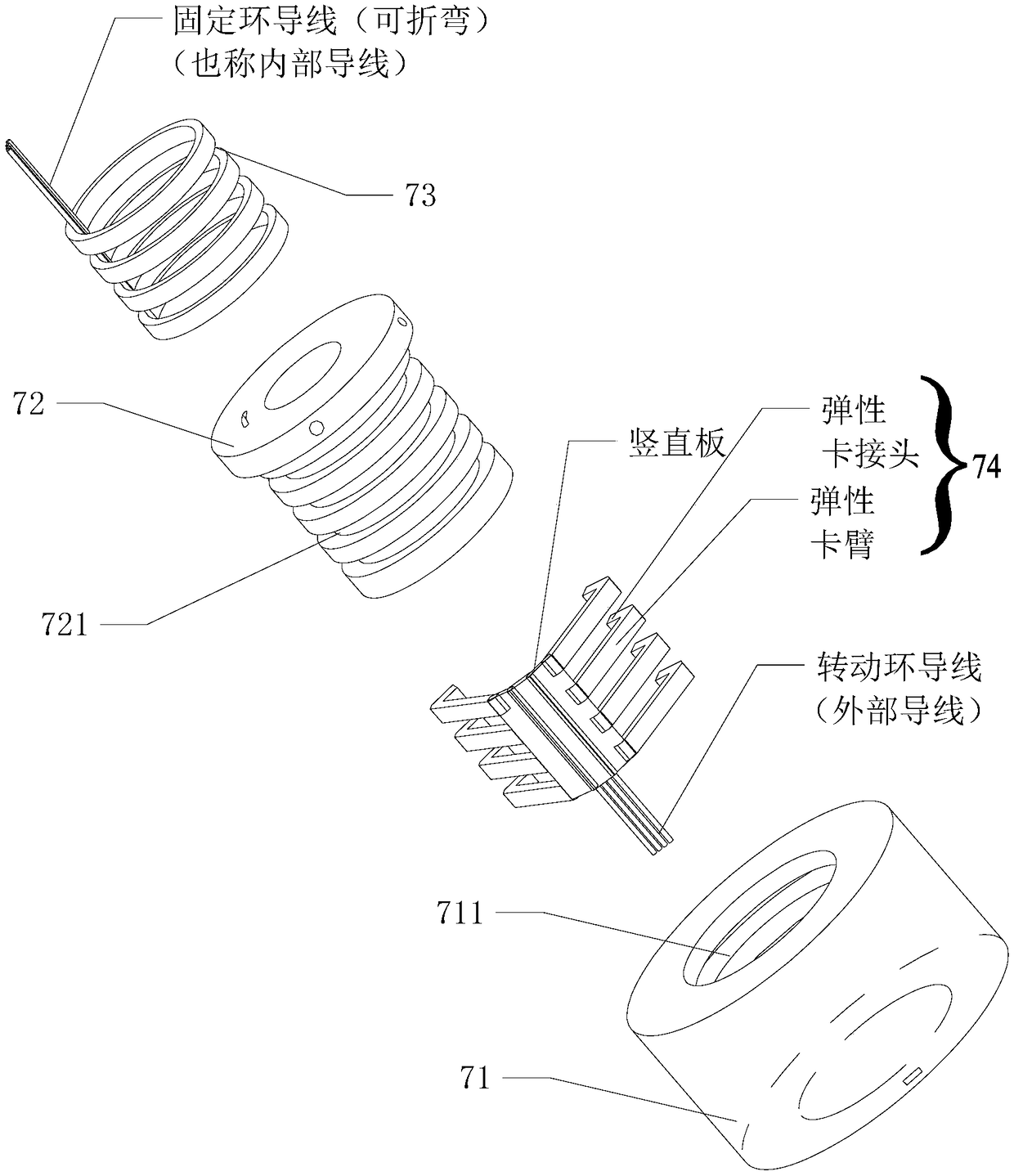

[0053] A robot joint module, comprising a straight shaft 1, and further comprising: a front magnetic adjustment support 2, a rear magnetic adjustment support 3, a magnetic adjustment armature 4, a circuit board 5, a stator core 6 and a slip ring 7;

[0054] The front magnet adjustment bracket 2 is sleeved on the outer circumference of the front end of the direct shaft 1, and the rear magnet adjustment bracket 3 is sleeved on the outer circumference of the rear section of the direct shaft 1; the rear magnetic adjustment bracket 3 protrudes forward from the first ring-shaped surrounding part 31 , the front magnetic adjustment bracket 2 protrudes backward from the second annular wrapping part 21; the two ends of the magnetic adjustment armature 4 are respectively plugged into the front end surface of the first annular wrapping part 31 and the rear end surface of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com