Brick straightening and loading machine

A car loading machine and component technology, applied in the field of brick car loading machine, achieves the effects of fast speed, easy rotation, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

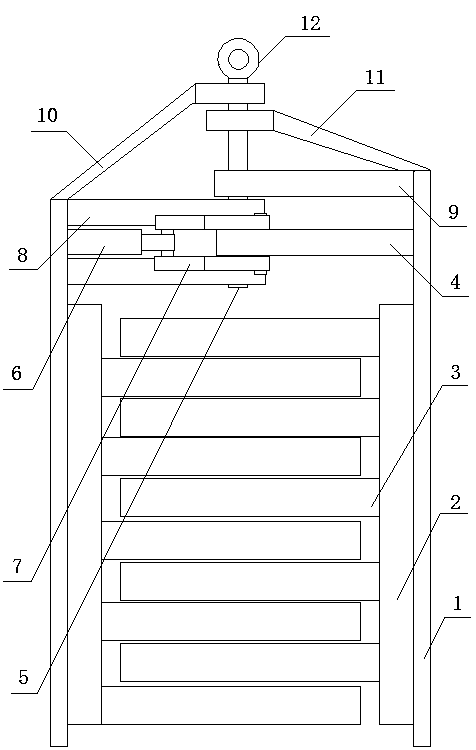

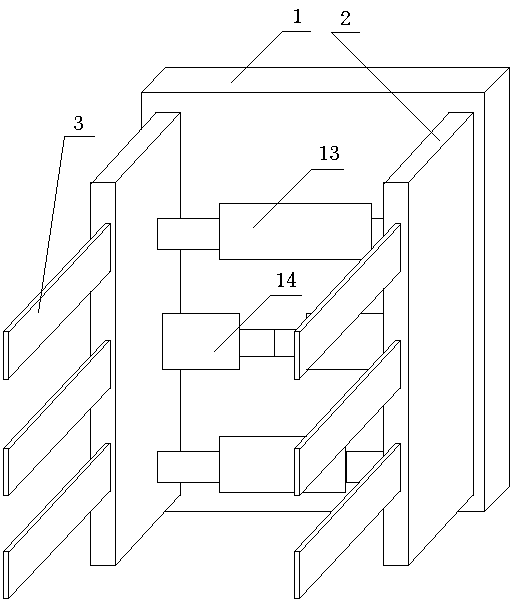

[0014] like figure 1 , 2 As shown, a brick straightening loading machine includes a clamp arm assembly I and a clamp arm assembly II, a hinge assembly connecting the clamp arm assembly I and the clamp arm assembly II, and a hydraulic control assembly. The hinge assembly is installed on the clamp arm assembly I and the top of the clamp arm assembly II, and make the clamp arm assembly I and the clamp arm assembly II rotate with the hinge assembly; the clamp arm assembly I includes a main frame plate 1, two auxiliary frame plates 2 and several clamp arms 3, in At least two sliding sleeves 13 are arranged on the main frame plate 1, and two sub-frame plates 2 are installed on both sides of the sliding sleeves 13, and are connected with the sliding sleeves through sliding rods, and several clamping arms 3 are symmetrically installed on the two sub-frame plates 2 respectively. , at least one pair of hydraulic cylinders 14 are set between the two sub-frame plates 2, and the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com