Pantograph traction device of track train

A technology for pulling devices and rail trains, applied in current collectors, electric vehicles, vehicle components, etc., can solve the problems of low measurement accuracy of pantograph relaxation force, achieve the effects of improving assembly efficiency, compact structure, and enhancing calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

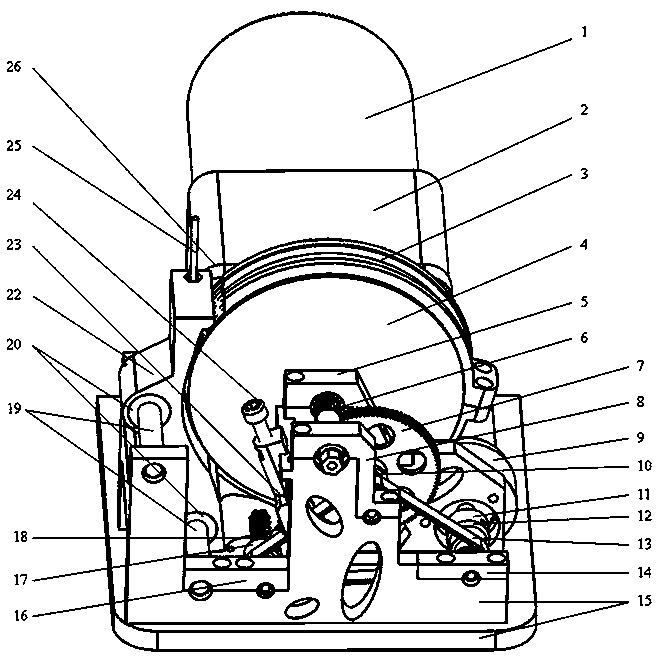

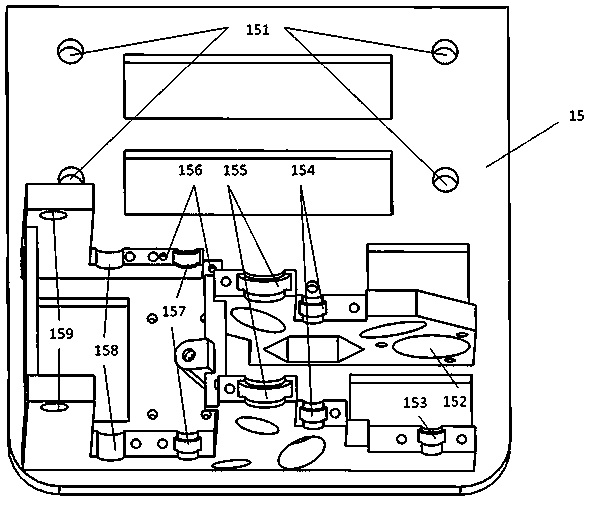

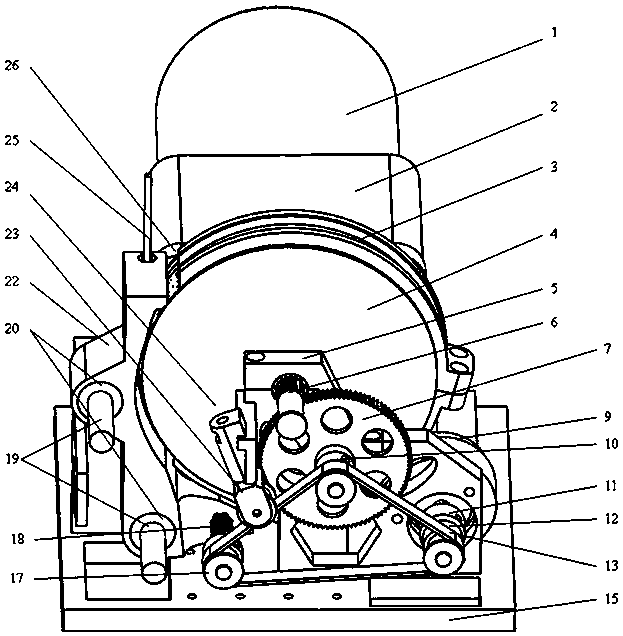

[0030] Specific embodiment one of rail train pantograph pulling device of the present invention, as Figure 1 to Figure 4 As shown, a mounting base 15 is included, and a driving mechanism is installed on the front half of the mounting base 15 through a mounting hole 151 , and the driving mechanism includes a driving motor 1 and a reducer 2 . In this embodiment, the second half of the mounting base 15 is equipped with a synchronous combination unit composed of a cable straightener 22, a rotary potentiometer 9 and a reduction mechanism integrated through a fixed frame, and the fixed frame includes front and rear frames arranged at intervals. body.

[0031] The output shaft of the speed reducer of the driving mechanism is equipped with a winding wheel 4, which is provided with a spiral winding groove on the peripheral surface of the winding wheel 4. The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com