Pressure error compensation method of vibration cylinder pressure sensor under variable temperature condition

A pressure sensor and error compensation technology, applied in the field of sensors, can solve the problems of error, discrete thermal conductivity of thermally conductive silicone rubber, large pressure, etc., and achieve the effect of solving the increase of error and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention are described below to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those skilled in the art, as long as various changes Such changes are obvious within the spirit and scope of the present invention as defined and determined by the appended claims, and all inventions and creations utilizing the inventive concept are within the scope of protection.

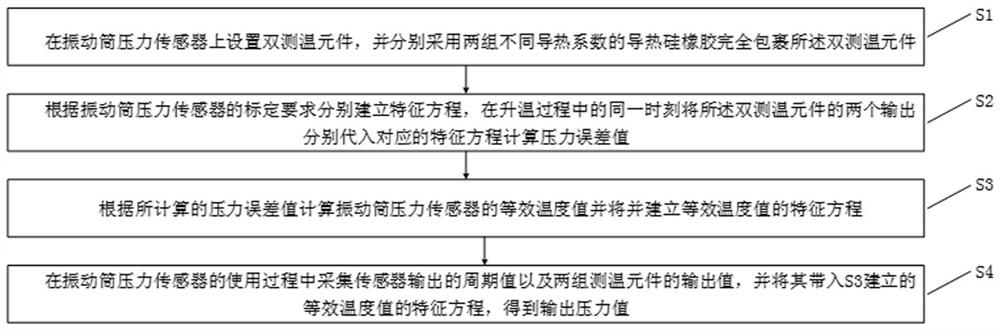

[0031] A pressure error compensation method for a vibrating cylinder pressure sensor under variable temperature conditions, such as figure 1 shown, including the following steps:

[0032] S1. Double temperature measuring elements are arranged on the vibrating cylinder pressure sensor, and two sets of thermally conductive silicone rubbers with different thermal conductivity are respectively used to completely wrap the double temperature mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com