Hoisting device for spare tire of truck

A hoisting device and spare tire technology, applied in the field of trucks, can solve problems such as large energy consumption, large shaking, and easy slipping of iron chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

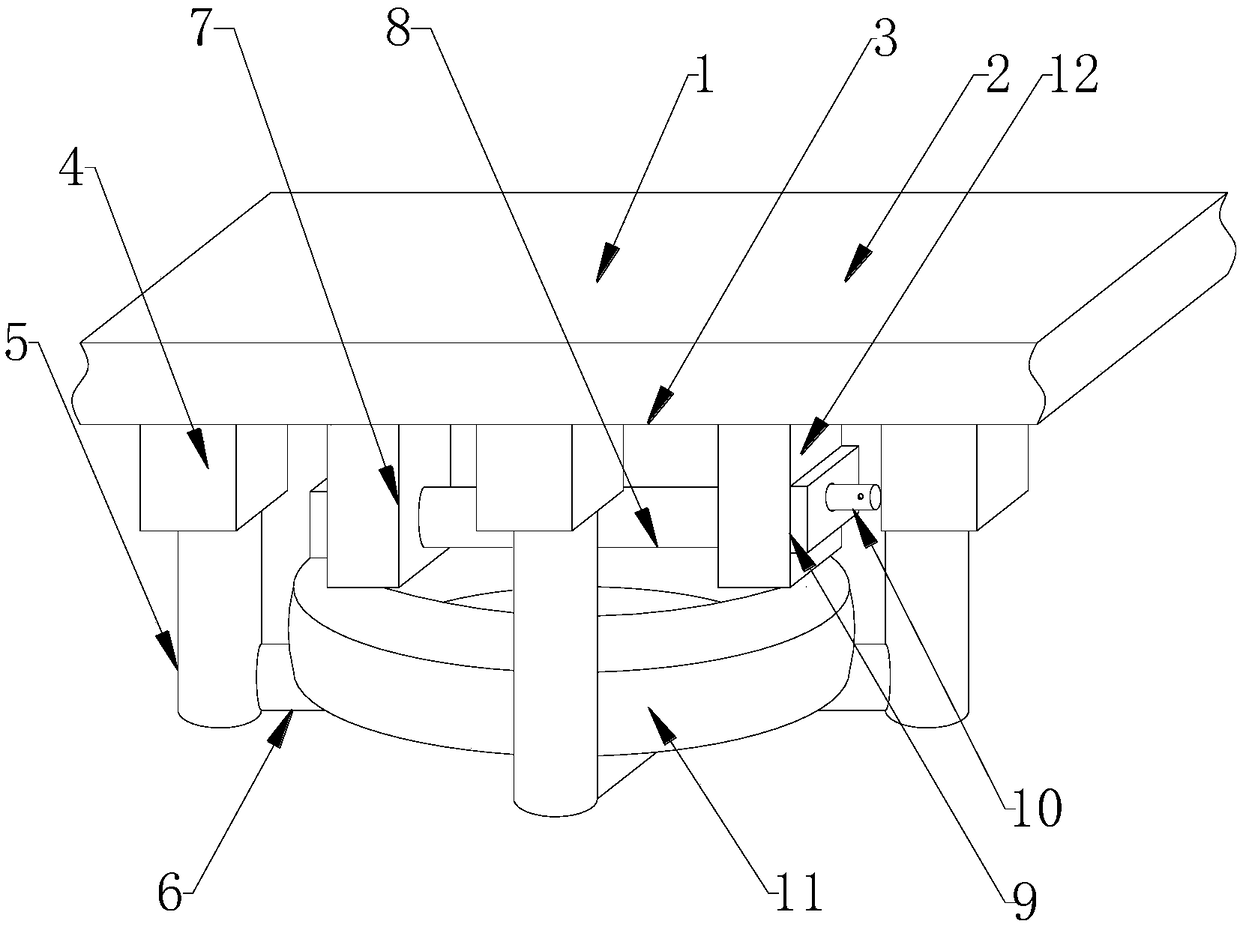

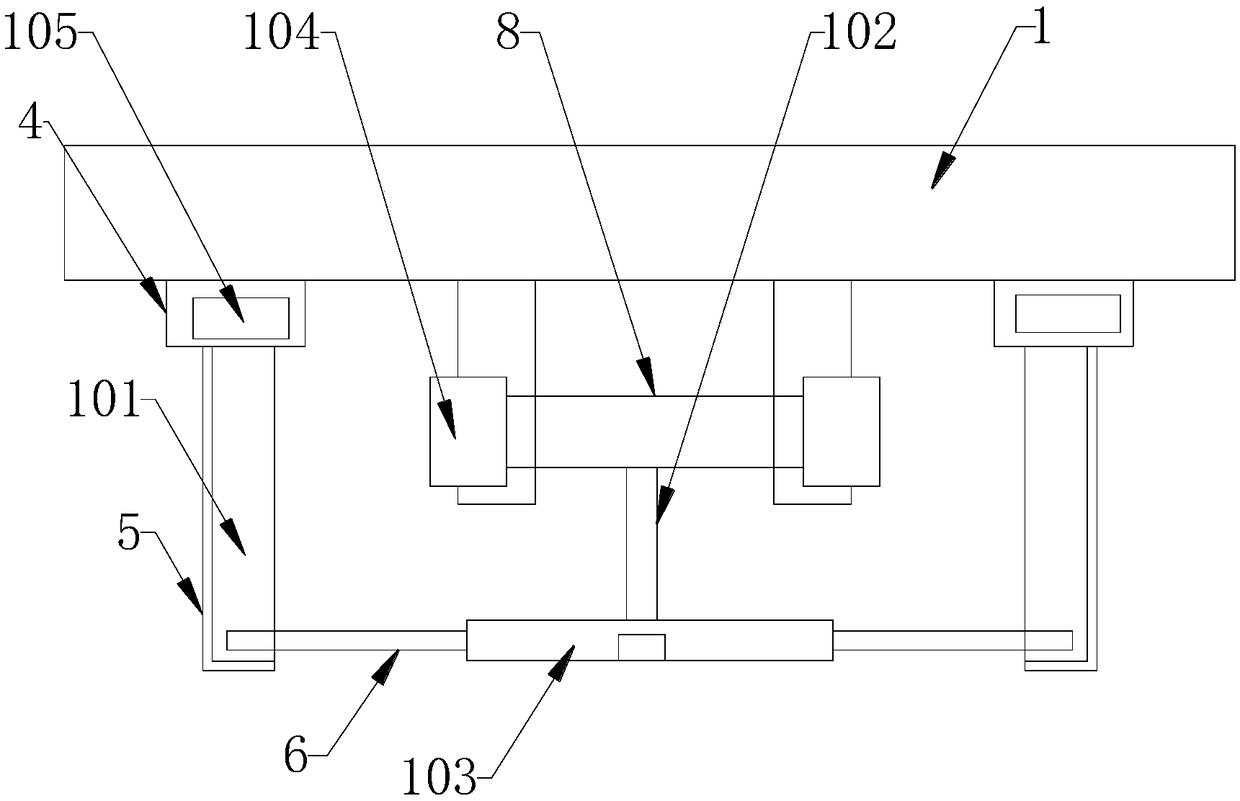

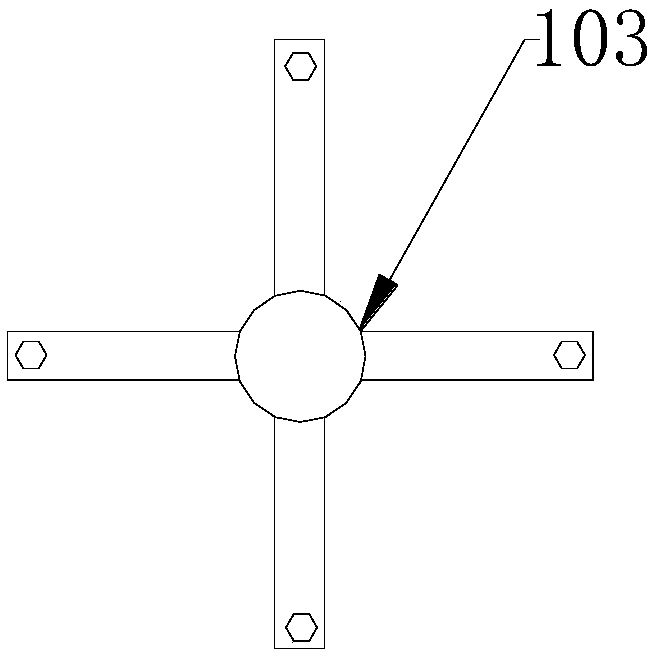

[0021] Specifically, if Figure 1 to Figure 4 As shown, it includes device main body 1, hoisting device 3, vehicle frame bottom plate 2 and hoisting device 3, vehicle frame bottom plate 2 is arranged on the top of device main body 1, vehicle frame bottom plate 2 is fixedly connected with device main body 1, and the bottom of vehicle frame bottom plate 2 A hoisting device 3 is provided, and the hoisting device 3 is movably connected with the frame bottom plate 2. The top of the hoisting device 3 is provided with four connecting plates 4, the connecting plates 4 are fixedly connected with the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com