Process for aseptic filling of beverage packaging comprising an interior drinking straw

A process, straw technology, applied in the field of systems performing the process, can solve the problems of component degradation or poor taste, high thermal load of beverages and packaging, energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

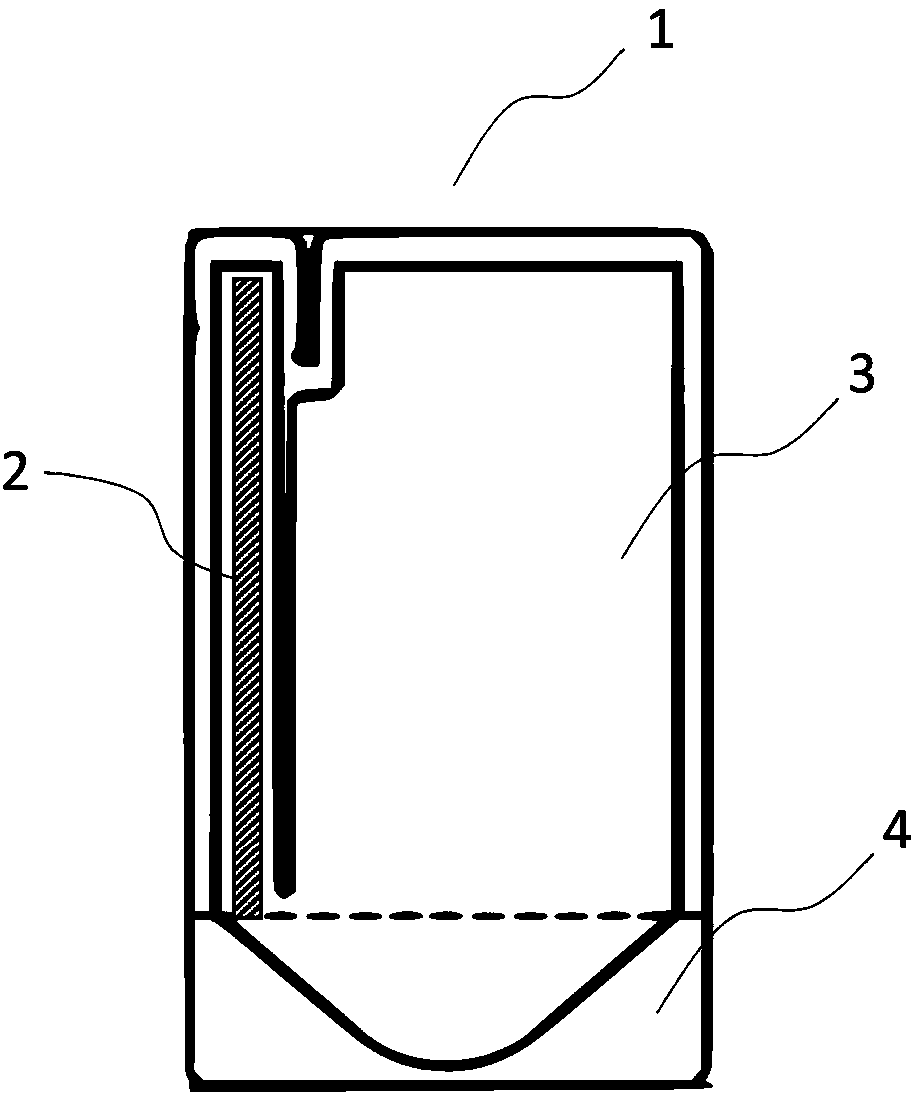

[0063] figure 1 A sachet package (1) containing a drinking straw (2) is shown. A drinking straw (2) is integrated in the sachet package (1) and extends into the beverage (3) contained in the sachet package. The pouch (1) is made of film material (4). This packaging enables safe and convenient application.

[0064] figure 2 A side view of the drinking sachet (1) is shown. The drinking straw (2) inside the package is not shown.

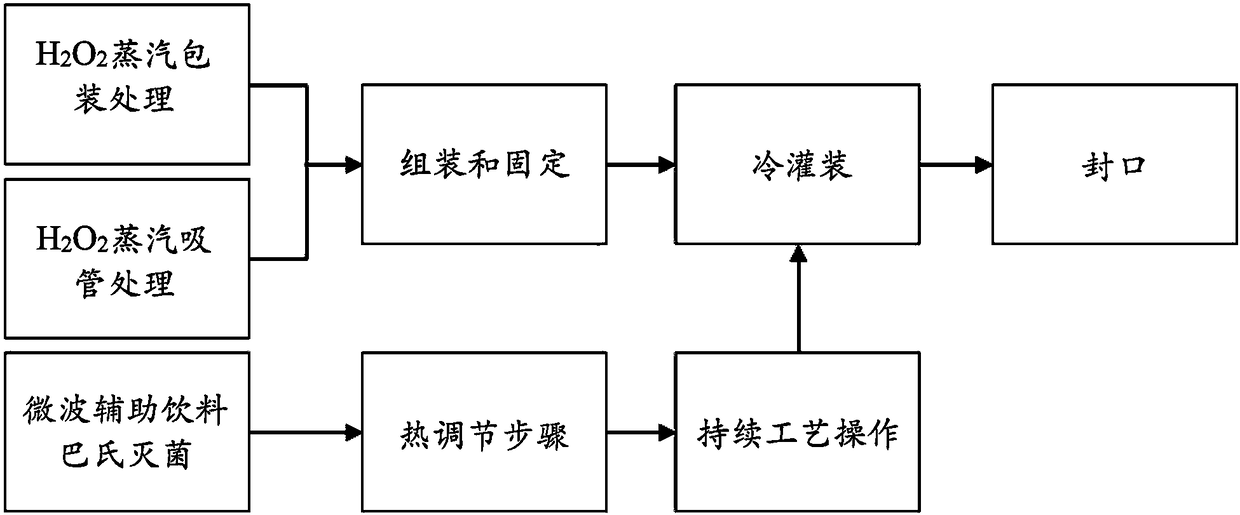

[0065] image 3 is a schematic diagram of the process of the present invention. In the first step, the beverage is pasteurized using microwave-assisted pasteurization. The output of the pasteurization step is sent to a heat conditioning step where the temperature of the beverage is regulated by a heat exchange device. The temperature-controlled pasteurized beverage is directed to the cold-fill process, or the pasteurized liquid can be transferred to a buffer. Both possibilities ensure a continuous production process. The beverage packaging an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com