Low-phosphorus SA542TypeDCL4a steel plate and production method thereof

A production method and steel plate technology, applied in the field of metallurgy, can solve problems such as harsh service conditions and unsatisfactory requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

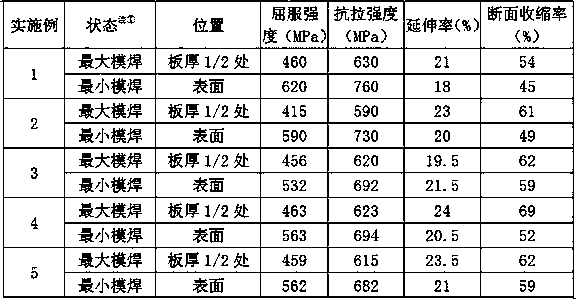

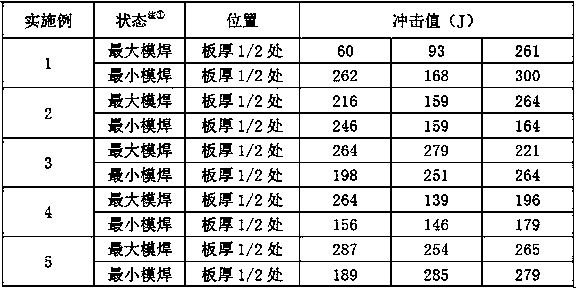

Examples

Embodiment 1

[0017] The chemical composition and mass percentage of the low-phosphorus SA542TypeDCL4a steel plate of this embodiment are: C: 0.15%, Si: 0.1%, Mn: 0.53%, Cr: 2.4%, Mo: 1.1%, V: 0.35%, S: 0.005%, P: 0.005%, the balance is Fe and inevitable impurity elements.

[0018] The production method of low-phosphorus SA542TypeDCL4a steel plate in this embodiment includes steelmaking, heating rolling and heat treatment processes. The specific process steps are as follows:

[0019] (1) Steelmaking: adopt electric arc furnace + refining furnace + die casting production process to make steel and prepare steel ingots, control the P in the molten steel after the electric arc furnace tapping: 0.004%, and control the P: 0.002% after the removal of P in the refining furnace; steel The liquid keeps vacuuming time for 20min, after vacuuming, the standing time is 10min;

[0020] (2) Heating and rolling: the steel ingot is heated and kept warm in a soaking furnace at a heating temperature of 1280°C for 3 ...

Embodiment 2

[0025] The chemical composition of the low-phosphorus SA542TypeDCL4a steel sheet and its mass percentage content in this embodiment are: C: 0.10%, Si: 0.08%, Mn: 0.40%, Cr: 2.1%, Mo: 0.9%, V: 0.30%, S: 0.004%, P: 0.003%, the balance is Fe and unavoidable impurity elements.

[0026] The production method of low-phosphorus SA542TypeDCL4a steel plate in this embodiment includes steelmaking, heating rolling and heat treatment processes. The specific process steps are as follows:

[0027] (1) Steelmaking: adopt electric arc furnace + refining furnace + die casting production process to make steel and prepare steel ingots, control P in molten steel after electric arc furnace tapping: 0.003%, control refining furnace P after de-P: 0.002%; steel The liquid keeps vacuuming time for 22min, after vacuuming, the standing time is 12min;

[0028] (2) Heating and rolling: the steel ingot is heated and kept in a soaking furnace at a heating temperature of 1230°C for 4 hours. After the billet is ope...

Embodiment 3

[0033] The chemical composition and mass percentage of the low-phosphorus SA542TypeDCL4a steel sheet of this embodiment are: C: 0.13%, Si: 0.07%, Mn: 0.52%, Cr: 2.3%, Mo: 0.99%, V: 0.32%, S: 0.005%, P: 0.004%, the balance is Fe and unavoidable impurity elements.

[0034] The production method of low-phosphorus SA542TypeDCL4a steel plate in this embodiment includes steelmaking, heating rolling and heat treatment processes. The specific process steps are as follows:

[0035] (1) Steelmaking: adopt electric arc furnace + refining furnace + die casting production process to make steel and prepare steel ingots, control the P in the molten steel after the electric arc furnace tapping: 0.004%, and control the P: 0.001% after the removal of P in the refining furnace; steel The liquid keeps vacuuming time for 23min, after vacuuming, the standing time is 13min;

[0036] (2) Heating and rolling: the steel ingot is heated and kept in a soaking furnace at a heating temperature of 1250°C for 3.3h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com