An ultra-high antibacterial performance austenitic stainless steel for medical implant stents

An austenitic stainless steel and performance technology, applied in the field of ultra-high antibacterial performance austenitic stainless steel materials and their preparation, can solve the problems of human health impact, reduced service life time, inability to apply, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

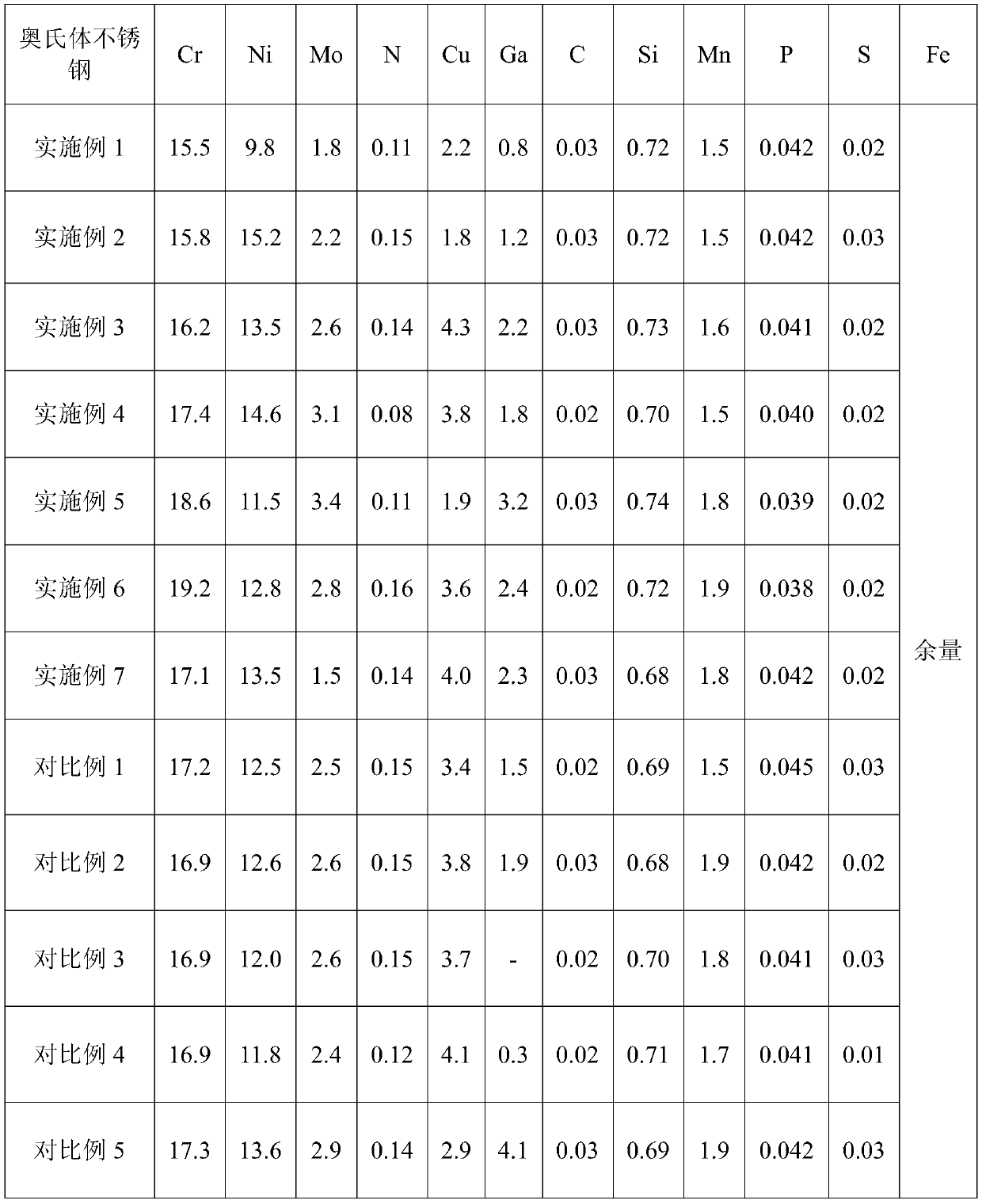

[0026]According to the chemical composition range set by the ultra-high antibacterial performance austenitic stainless steel material, the present invention adopts 15 kilograms of vacuum induction furnace to smelt the embodiment and comparative example to forge 10 kilograms of ultra-high antibacterial performance austenitic stainless steel respectively, and its chemical composition is shown in Table 1 .

[0027] The main chemical composition (wt.%) of the austenitic stainless steel of table 1 embodiment and comparative example

[0028]

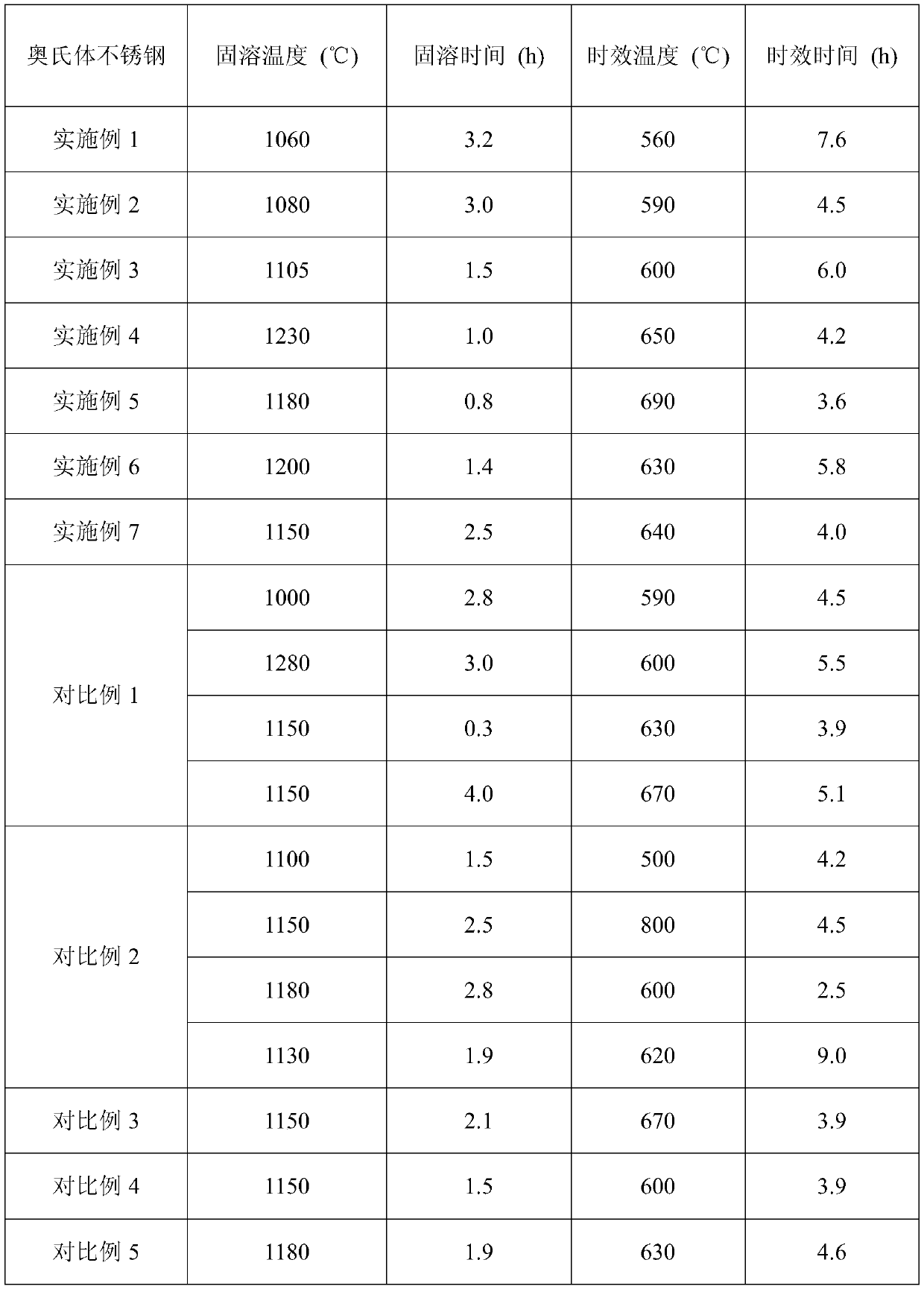

[0029] According to the parameter range of the heat treatment method set by the ultra-high antibacterial performance austenitic stainless steel of the present invention, the detailed parameters of the solid solution and aging heat treatment formulated are shown in Table 2.

[0030] The heat treatment process parameter of table 2 embodiment and comparative example

[0031]

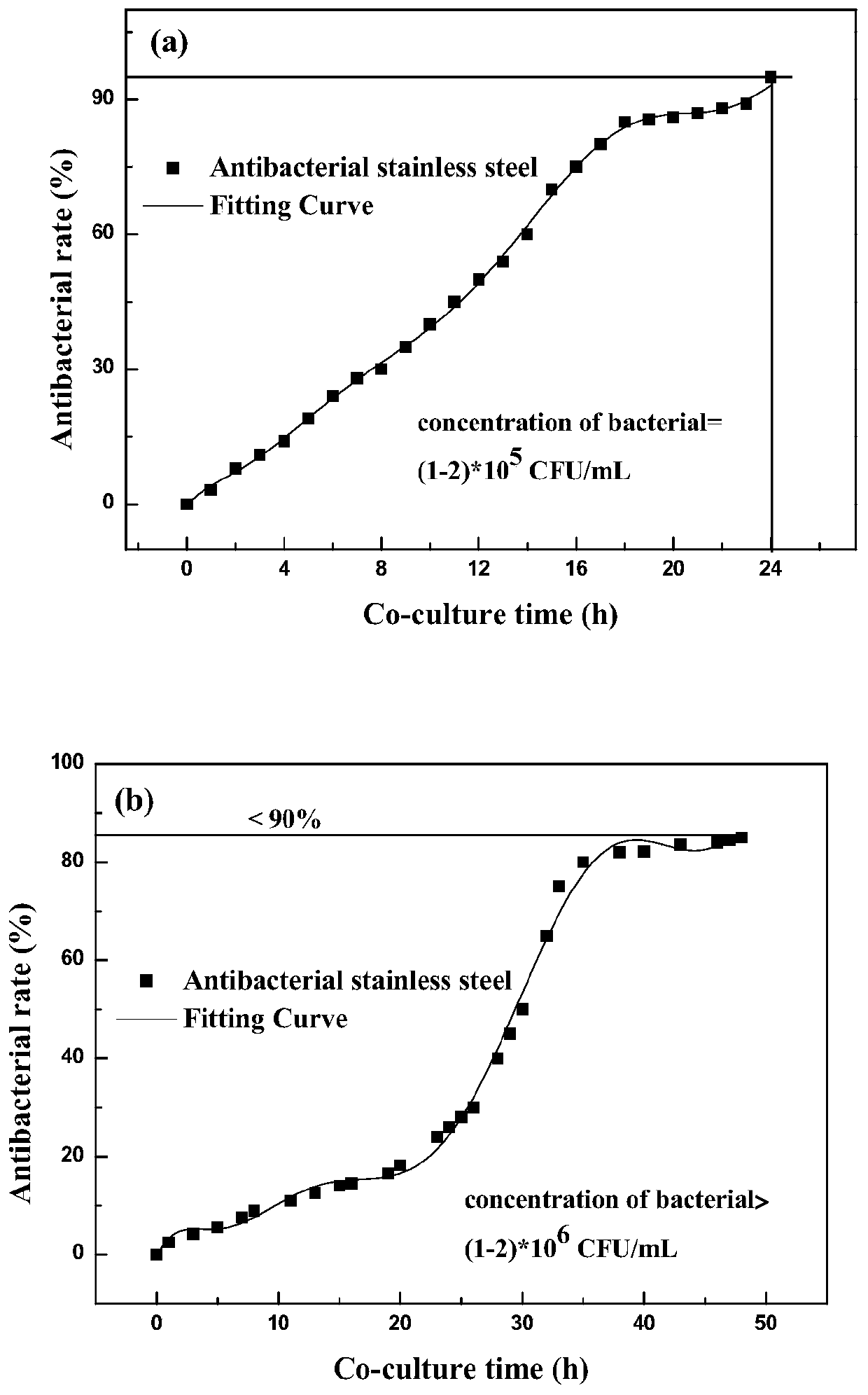

[0032] 1. In vitro antibacterial performance test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com