Ditching equipment for burying a petroleum pipeline underground

A technology for oil pipelines and equipment, applied in the field of trenching equipment, which can solve problems such as dust influence, high labor intensity, and slow trenching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

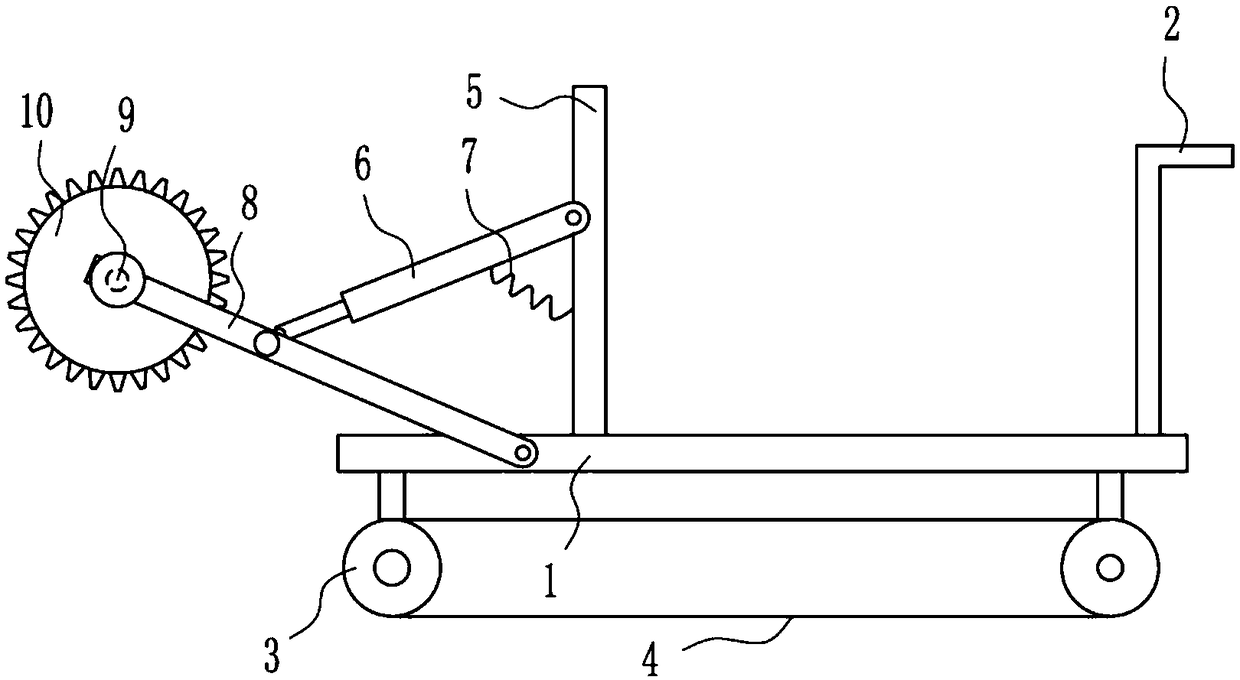

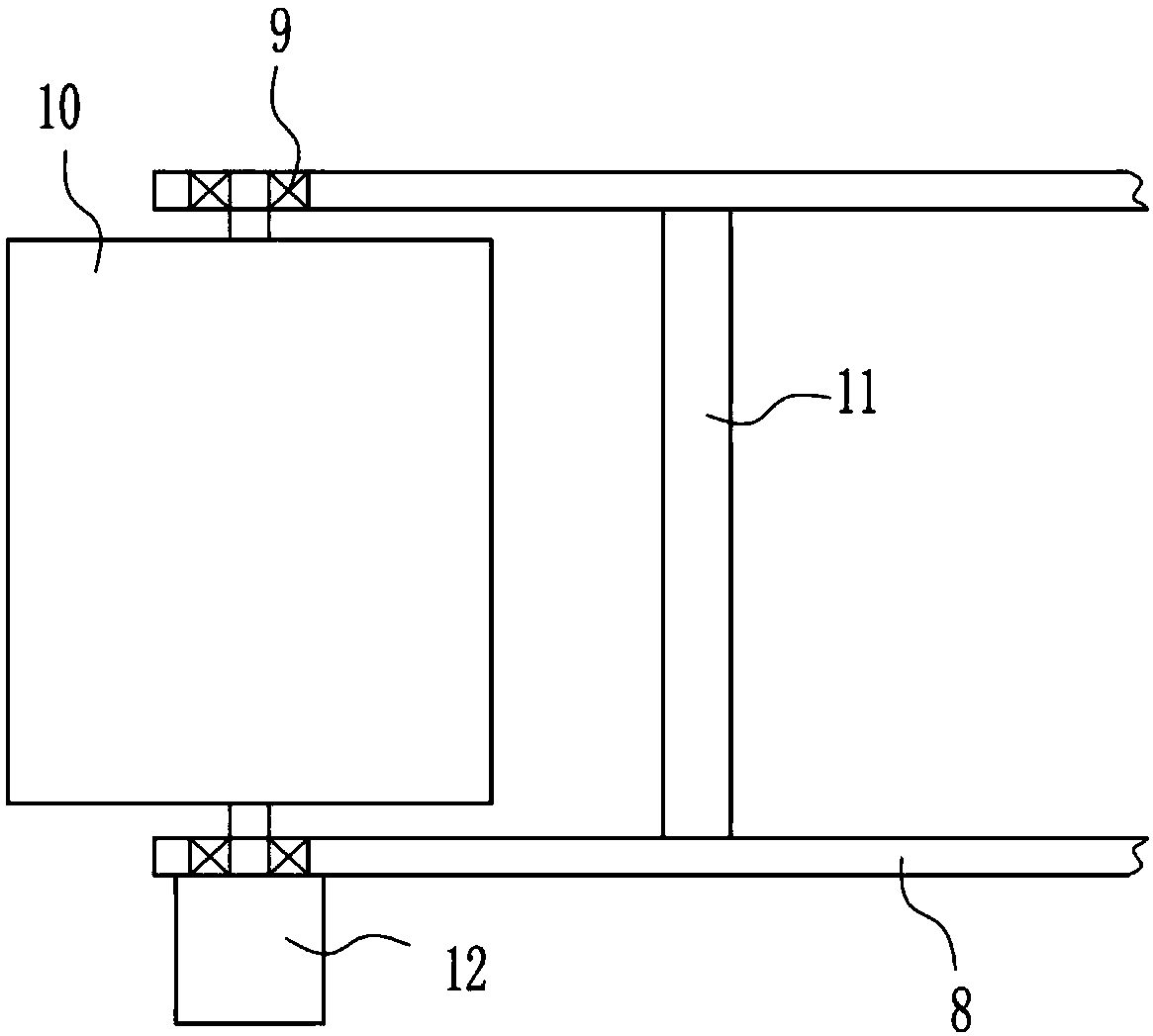

[0022] A kind of trenching equipment for buried oil pipeline, such as Figure 1-5 As shown, it includes base plate 1, push handle 2, sprocket wheel 3, chain belt 4, vertical rod 5, cylinder 6, first spring 7, movable plate 8, first bearing seat 9, crushing wheel 10, connecting rod 11 and the first A motor 12, a push handle 2 is installed on the right side of the top of the base plate 1, a sprocket 3 is installed symmetrically on the left and right sides of the bottom of the base plate 1, and a chain belt 4 is connected between the sprockets 3 on the left and right sides, and the left side of the front side of the base plate 1 and The left side of the back side is rotatably equipped with a movable plate 8, and a connecting rod 11 is installed between the left side of the movable plate 8 on the front and rear sides, and the first bearing seat is installed on the left side of the movable plate 8 on the front and rear sides. 9. A crushing wheel 10 is connected between the first be...

Embodiment 2

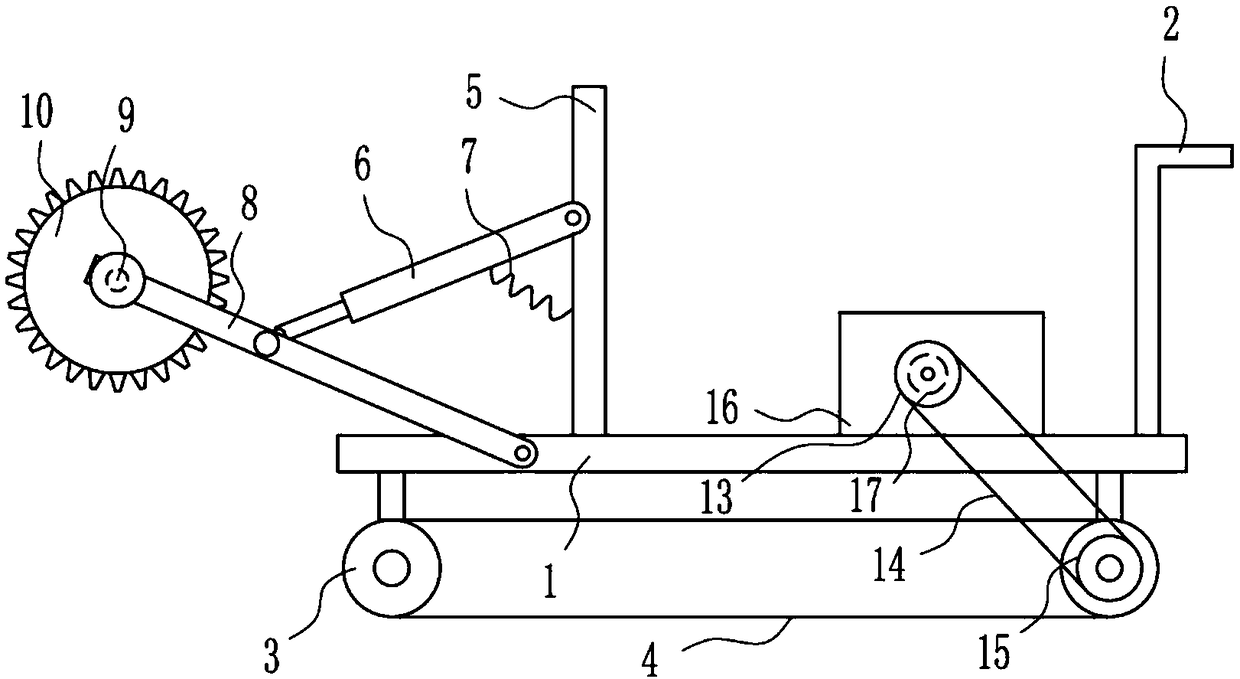

[0024] A kind of trenching equipment for buried oil pipeline, such as Figure 1-5As shown, it includes base plate 1, push handle 2, sprocket wheel 3, chain belt 4, vertical rod 5, cylinder 6, first spring 7, movable plate 8, first bearing seat 9, crushing wheel 10, connecting rod 11 and the first A motor 12, a push handle 2 is installed on the right side of the top of the base plate 1, a sprocket 3 is installed symmetrically on the left and right sides of the bottom of the base plate 1, and a chain belt 4 is connected between the sprockets 3 on the left and right sides, and the left side of the front side of the base plate 1 and The left side of the back side is rotatably equipped with a movable plate 8, and a connecting rod 11 is installed between the left side of the movable plate 8 on the front and rear sides, and the first bearing seat is installed on the left side of the movable plate 8 on the front and rear sides. 9. A crushing wheel 10 is connected between the first bea...

Embodiment 3

[0027] A kind of trenching equipment for buried oil pipeline, such as Figure 1-5 As shown, it includes base plate 1, push handle 2, sprocket wheel 3, chain belt 4, vertical rod 5, cylinder 6, first spring 7, movable plate 8, first bearing seat 9, crushing wheel 10, connecting rod 11 and the first A motor 12, a push handle 2 is installed on the right side of the top of the base plate 1, a sprocket 3 is installed symmetrically on the left and right sides of the bottom of the base plate 1, and a chain belt 4 is connected between the sprockets 3 on the left and right sides, and the left side of the front side of the base plate 1 and The left side of the back side is rotatably equipped with a movable plate 8, and a connecting rod 11 is installed between the left side of the movable plate 8 on the front and rear sides, and the first bearing seat is installed on the left side of the movable plate 8 on the front and rear sides. 9. A crushing wheel 10 is connected between the first be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com