Integrated speed-regulating hydraulic valve group

A hydraulic valve group and speed regulation technology, which is applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve problems such as the top deviation of the distribution channel and hole collapse, and achieve the effect of avoiding top deviation and hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

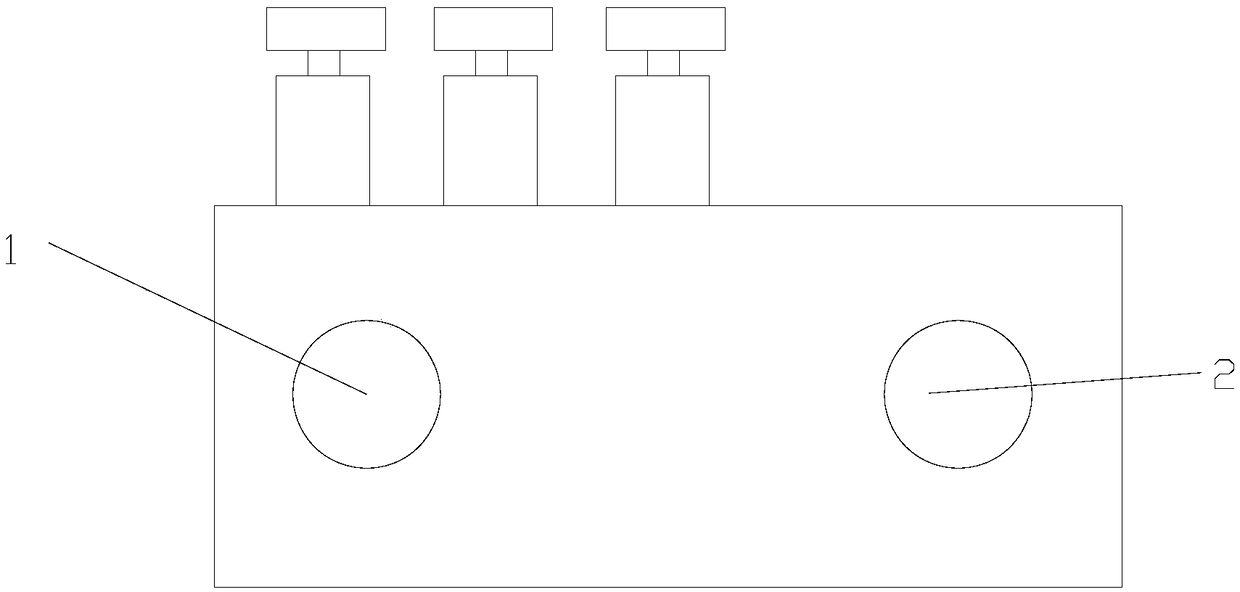

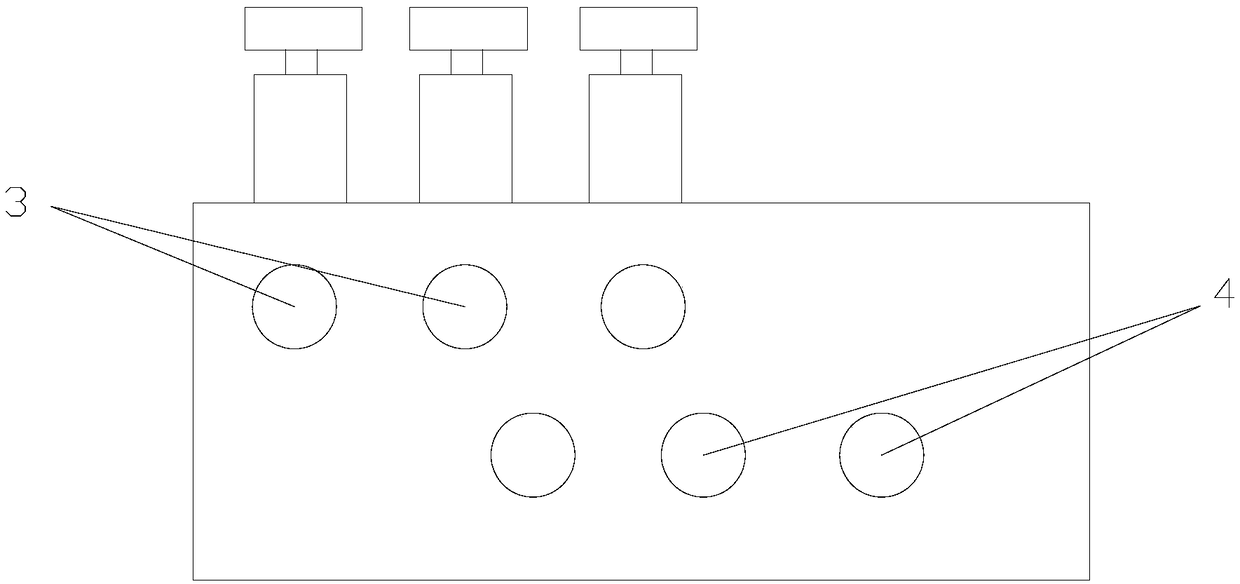

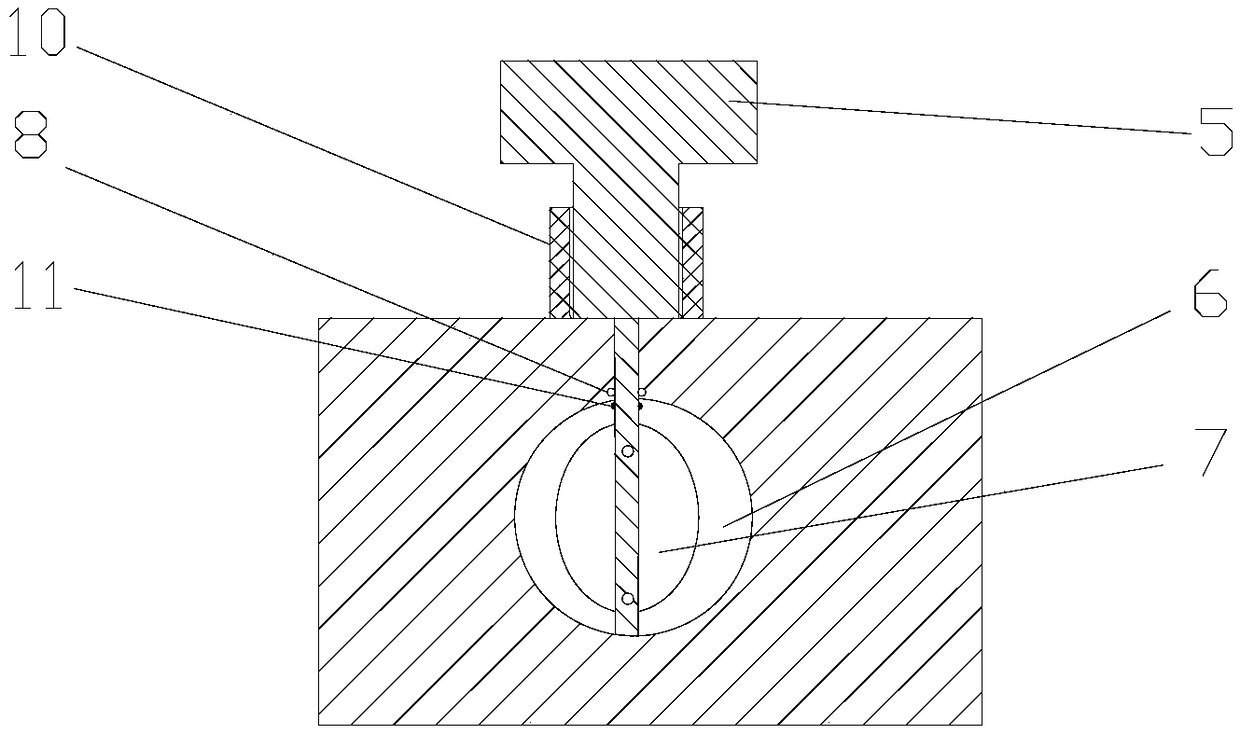

[0015] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 back view of the image 3 It is a structural schematic diagram of the speed regulating mechanism in the present invention. As shown in the figure, the integrated speed regulating hydraulic valve group in this embodiment includes a valve block, and the valve block is provided with a main oil inlet port 1 and a main oil return port 2 , a plurality of diversion outlets 3 and a plurality of diversion inlets 4, the total oil inlet communicates with a plurality of diversion outlets through a diversion passage arranged inside the valve block, and the total oil return port communicates with a plurality of diversion outlets through a confluence passage arranged inside the valve block It is connected with a plurality of diversion inlets, and also includes a speed regulating mechanism for independently adjusting the flow rate of the liquid in each diversion outlet; the number of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com