Unloading device

A technology of unloading device and sealing device, which is applied to the equipment loaded into the pressure vessel, the pressure vessel, and the equipment discharged from the pressure vessel, etc. It can solve the problems of foreign matter entering the pipeline, increasing operation complexity and uncontrollability, and achieves Simple unloading operation, avoiding frequent daily cleaning, saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

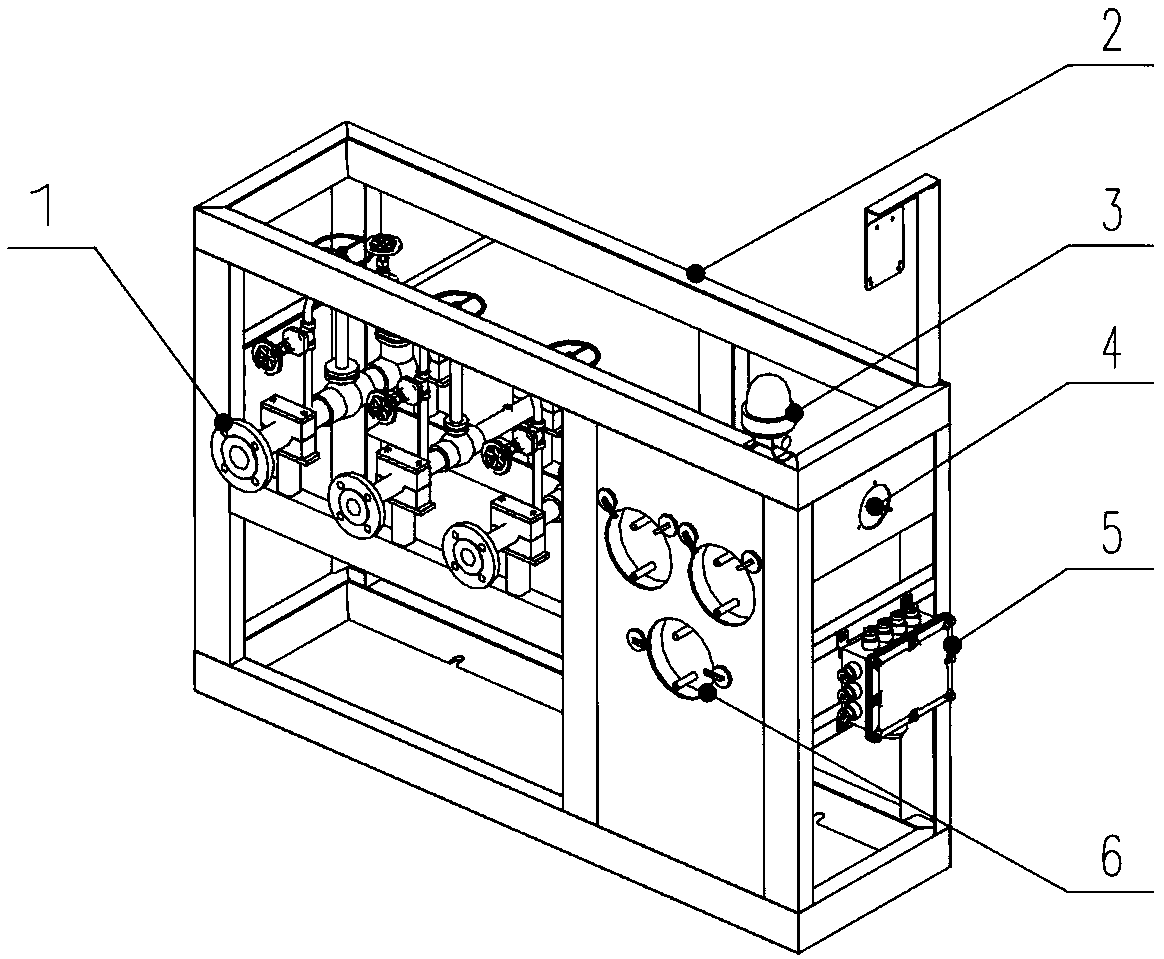

[0018] Such as figure 1 As shown, an unloading device includes a pipe assembly 1 and a frame assembly 2. The pipe assembly 1 connects the tank truck and the LNG storage tank when the LNG tank truck is unloading liquid to realize the transportation of LNG. The pipe assembly 1 is arranged on the frame On the assembly 2, the frame assembly 2 is used to assemble the supporting pipes into 1. The unloading device also includes the unloading flange fixing and sealing device 6. The unloading flange fixing and sealing device 6 can provide the fixing and sealing of the unloading hose flange after the unloading is completed. For sealing function, the unloading flange fixing sealing device 6 is arranged on the frame assembly 2 .

[0019] The fixing and sealing device 6 of the unloading flange is composed of a flange fixing plate, a flange sealing gasket and a rotating fixed lock. There is a flange sealing gasket inside, and at least 2 rotating and fixing locks are arranged on the outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com