Device for quantitatively measuring micro rotating torque of gear in real time and use method thereof

A rotational torque, real-time quantitative technology, applied in the field of measurement, can solve the problems of indeterminate quantification, difficult adjustment of rotational torque, failure, etc., to achieve the effect of increasing stability and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

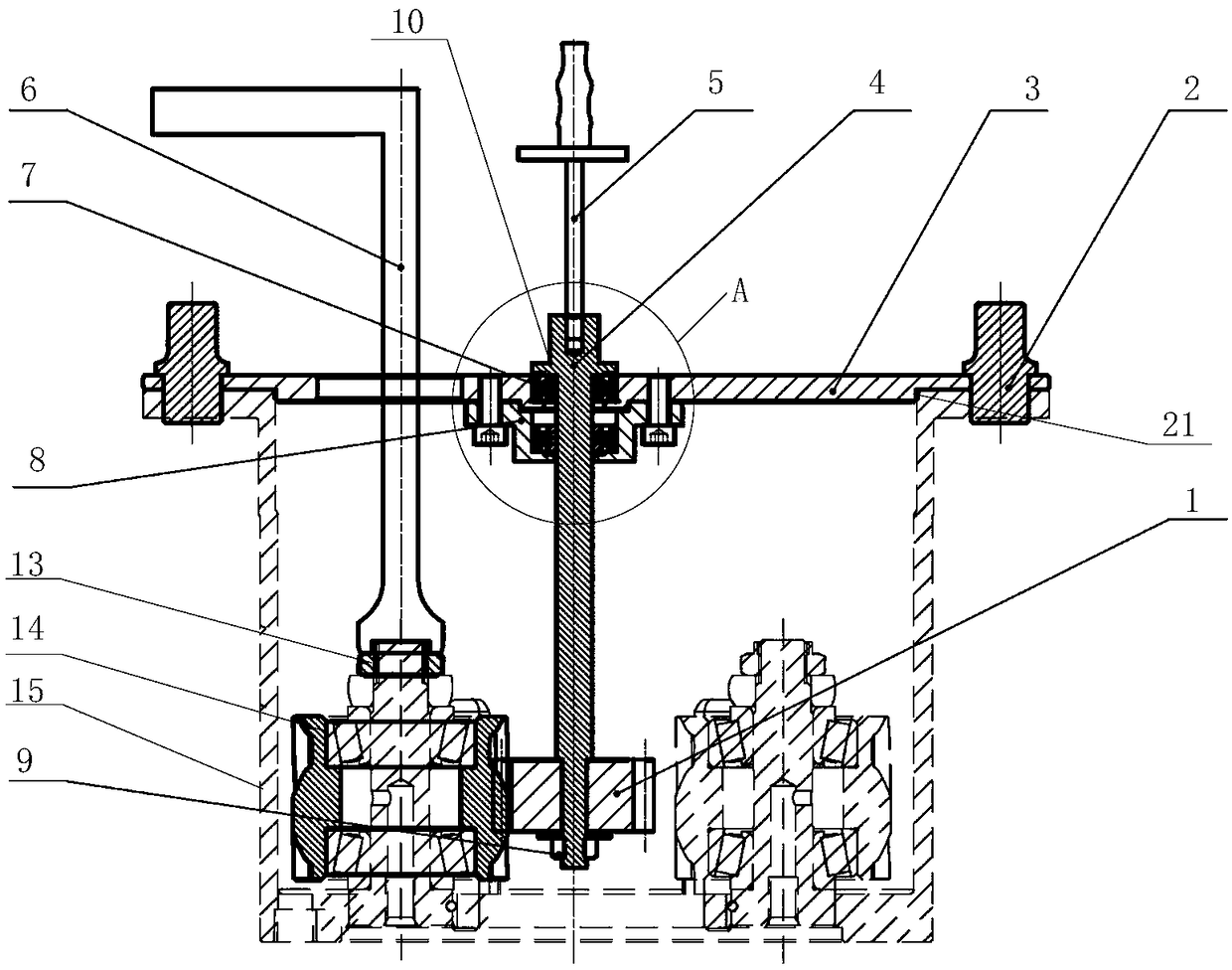

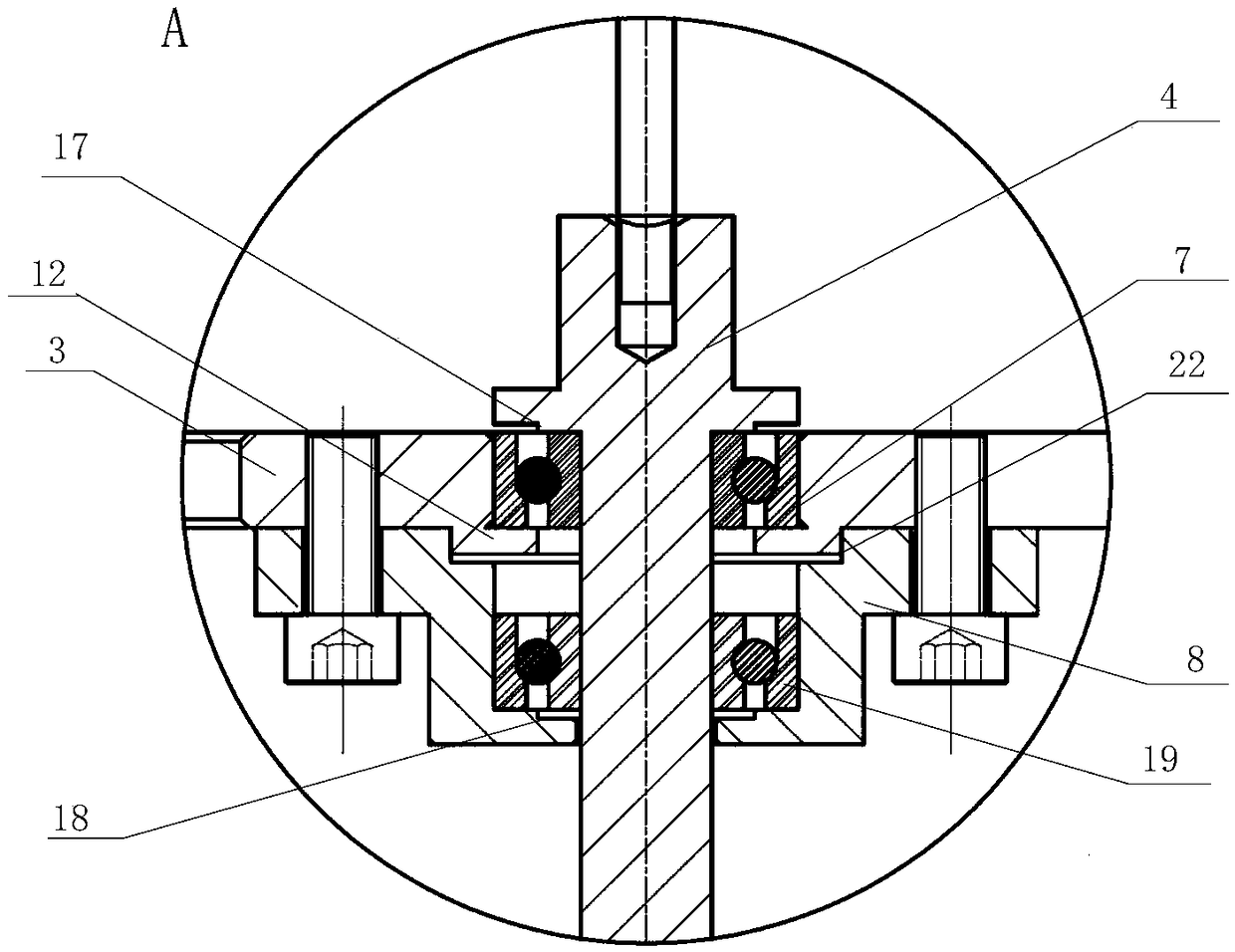

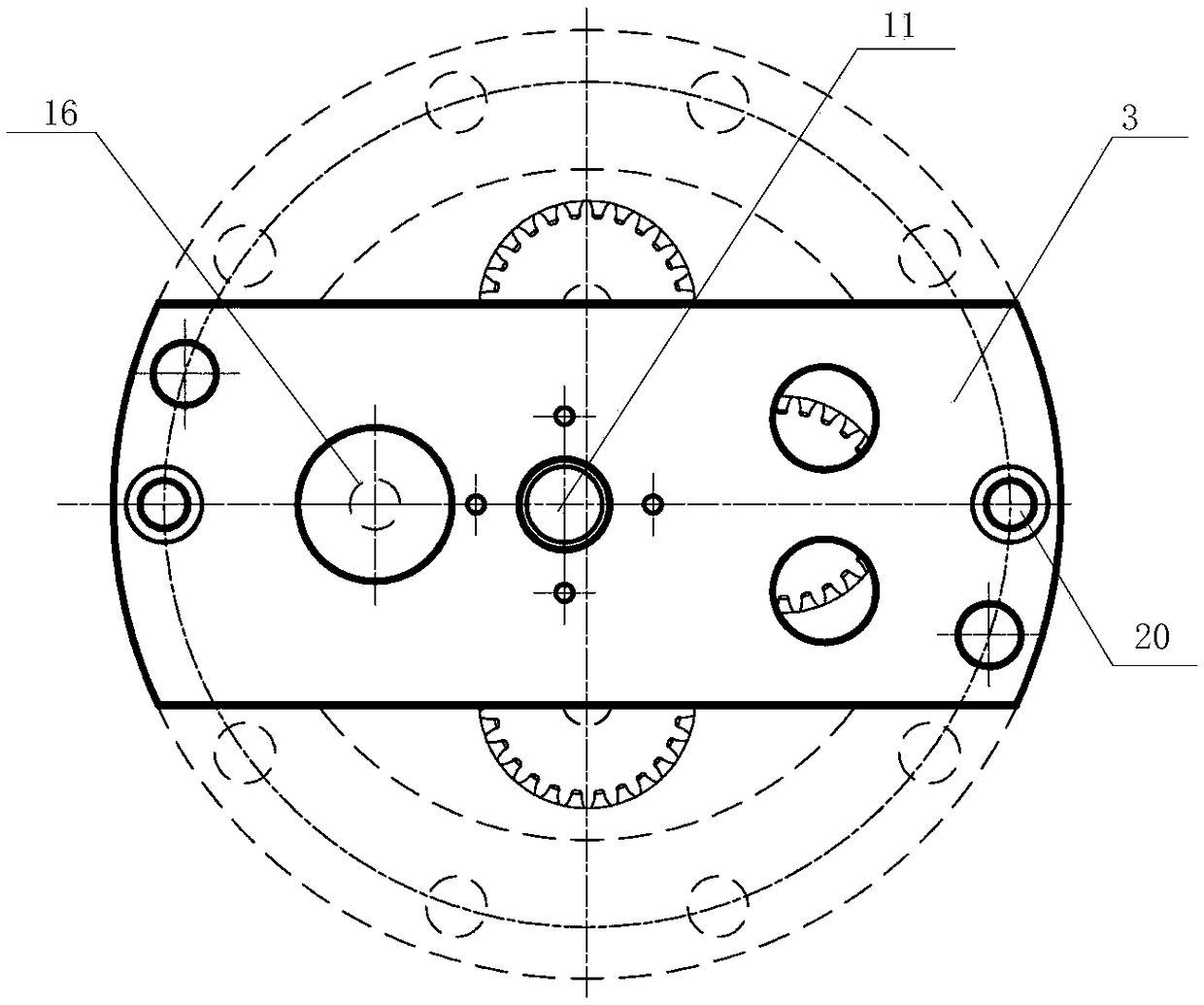

[0055] (1) Place the support plate 3 on the upper edge of the planet carrier 15 to be measured, and position it with the first notch 21 .

[0056] (2) After confirming that the transmission gear 1 is meshed with the planetary gear 14, use the two positioning pins 2 to completely position the support plate 3.

[0057] (3) Insert the dial type torque screwdriver 5 in the inner square hole of the transmission shaft 4, after the fixed torque wrench 6 passes through the second through hole 16, insert the head of the locking nut 13 on the upper end of the planetary wheel 14.

[0058] (4) Rotate the dial-type torque screwdriver 5 at a constant speed and observe the scale of the dial-type torque screwdriver 5. If the indicated value is greater than the upper limit of the rotational torque, turn the fixed torque wrench 6 counterclockwise to loosen the lock nut 13; if the indicated value If it is less than the lower limit of the rotational torque, turn the fixed torque wrench 6 clockwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com