Elastic-tooth returning-straw burying operation assembly

A spring-tooth and straw technology, which is applied in agriculture, farming machines, agricultural machinery and machines, etc., can solve the problem that the burial rate and burial depth of returning straw cannot meet the farming standards for no-tillage operations, and the land cannot adapt to less tillage Or the requirements of no-tillage and sowing operations, and the impact on the popularization and application of straw returning agronomic techniques, etc., to achieve the effect of reasonable force, novel structure, and smooth land surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

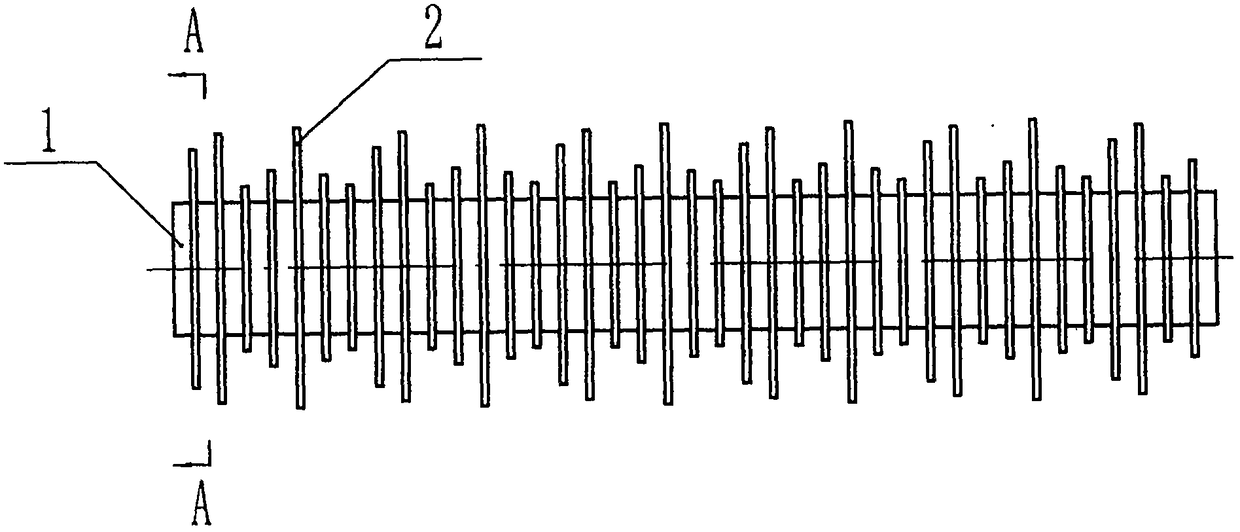

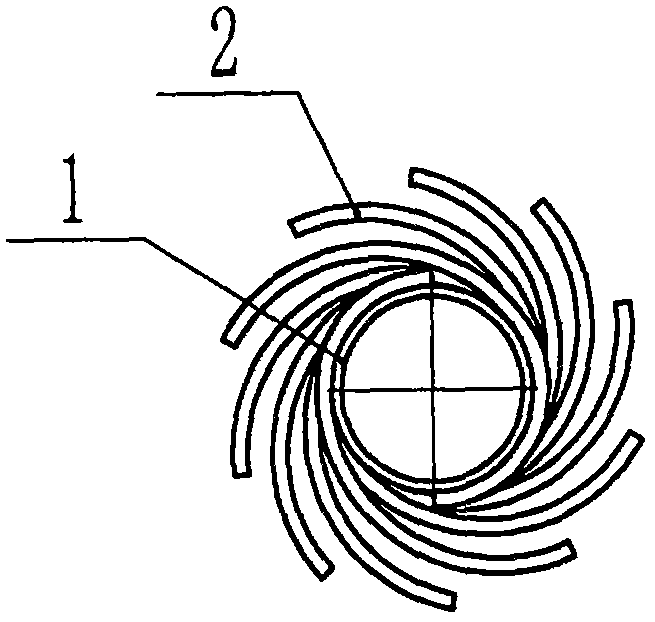

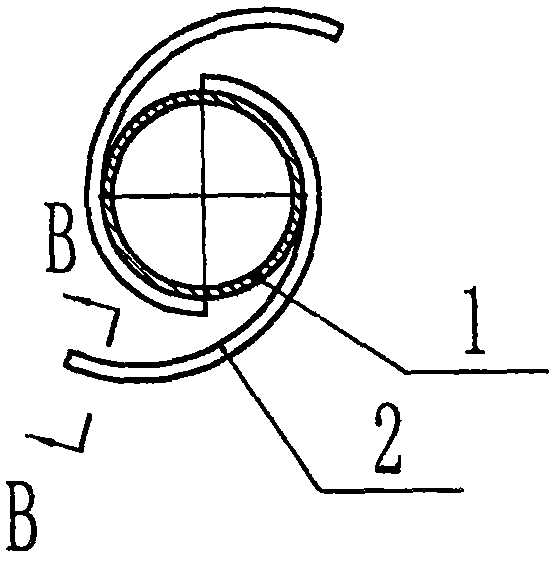

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A spring-tooth-type straw burying operation assembly for field returning. On the assembly shaft 1, N spring teeth 2 are evenly arranged in a double-headed helical arrangement along the axial direction. The spring teeth 2 are composed of a fixed section 4 It is connected with the buried operation section 3. The fixed section 4 is in the shape of an arc surface as a whole, and the radius size of the inner surface of the arc surface matches the radius size of the outer surface of the assembly shaft 1. The overall embedded operation section 3 It is involute surface shape, and the cross-section of the buried operation section 3 is rectangular.

[0014] During operation, the actively rotating assembly shaft 1 drives the spring tooth 2 to rotate, and the spring tooth 2 presses the returning straw into the soil after rotary tillage and crushing to complete the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com